When we last left our intrepid swapper he was enjoying a burger and beer in Crown King after enjoying the fuel-sipping economy of a 6.2L GM diesel. At that point, I should have simply been happy with the swap, cleaned up a few odds and ends (i.e. wiring), and started on some bodywork to fix the previous wheeling damage. Had I done this I would have saved a bunch of money and time, and been using my truck for the last few years rather than working on it.

By this point my interests in wheeling and how I wanted to use my truck had changed dramatically. I was no longer interested in spending a day wheeling stupidly difficult terrain, only travelling a mile or three, damaging my truck, and not really going anywhere or doing anything. I preferred the type of wheeling I had just completed with the Hummer and Jeep guys, more of the scenic exploration over moderate terrain. I also wanted it to remain a camping and hunting rig - a RELIABLE camping and hunting rig! For these uses the increased range and economy were very welcome, but at 165HP I had lost 35HP over the gas engine, and it was most noticeable on mountainous highways. I had already researched adding a turbo, and in fact had laid my hands on a Holset HY-35 as well as a set of 6.5 turbo exhaust manifolds. I was also concerned about the future reliability of the 4L60 trans, so I had obtained a late model, aluminum-top SM465 manual transmission, but the trans swap wouldn't happen until after the 6.2 was turbo'd and had the fuel turned up.

Three things happened that would change my plans for the 6.2. The first was Nick's suburban build (the bastidge!!) This made me think a Cummins swap into my Blazer would be uber-cool, but I figured it would be too expensive and so I didn't really consider it too seriously at the time.

The second thing was another friends decision to do a 12V swap into his 1991 square body crew cab Chevy to replace his gas-swilling 454. Now, normally a Cummins swap donor comes in the form of either a complete Dodge truck, or an engine pulled from a Dodge truck, and the price tags are usually north of two grand for a real high miler and three+ for something between 100k and 150k miles. Minimum. Often they are even more.Then we found a guy who scraps out medium duty delivery trucks and busses and had P-pumped Cummins engines that he had pulled. And he was asking only a grand for a good runner! We went down there, fired one up, and it purred like a very loud kitten. Good oil pressure, minimal blowby, immediate starting, everything you look for, Cash changed hands and my friend hauled his prize home..

Which brings me to the third thing: I had just got my tax return from Uncle Sam, and it was way more than enough for one of these MD engines. I already had the Cummins itch, and now I had money burning a hole in my pocket. With a complete lack of forethought or planning I piled into my friend's crew cab, headed down to the guys yard, listened to another engine run, and traded money for a half ton of Cummins:

The first thing you notice is that it is BIG. The second is that it is incredibly scuzzy. It took a whole day of degreaser, oven cleaner, pressure washer, and elbow grease to get it cleaned up. The oven cleaner, pressure washer, and elbow grease also blew off much of the paint, so I had to paint it. I sprayed 5 Star Xtreme epoxy primer on first, since there was a fair bit of bare metal showing after the cleanup job. The paint used is Western's 3rd Dimension acrylic urethane in genuine Cummins beige (for future reference, the 3rd Dimension number for that color is DS-7366-A). I used 3rd dimension because I already had the reducer and hardener from another project, it's fairly durable, and it only costs $20 a pint.

Those who notice little details will see that the pic of the engine in the bed of the crew cab has a front sump and an SAE #2 flywheel housing, while the painted engine has a rear sump and a Dodge second-gen flywheel housing. The pan on a Cummins is reversible, but the oil pickup isn't. Getting a rear sump pickup required a trip to the local Freightshaker parts joint and trading the counter guy a sizeable wad of cash for the pickup I needed. The flywheel housing came from a guy on 4BT swaps and was much more reasonably priced. I also installed a new pan gasket and replaced the rear main seal, but that wouldn't be the last of the repairs needed before the engine could be installed.

When I had the pan off to rotate it and swap the pickup I decided to check the main and rod bearings. The mains were in excellent shape.

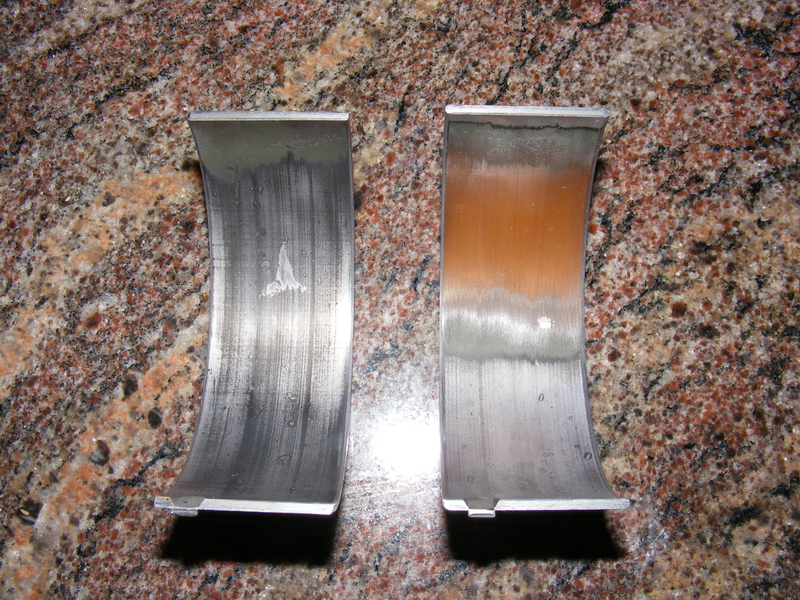

The rod bearings, not so much...

You can see the bearing material is completely worn off in one area of the top bearing half, exposing the copper layer beneath, while a strange mark is eroded into the other half (looks like a three pointed star). I did some research and found that the exposed copper is likely due to lugging the engine excessively, while the strange mark is cavitation erosion. The cavitation erosion is apparently common on Cummins rod bearings after enough hours are on the engine and don't seem to do any harm since that portion of the bearing is lightly loaded.. The lugging damage is not normal, but is expected from the types of folks who drive busses and delivery vans

Anyway, the crank surfaces were fine so I replaced the rod bearings with gen-u-ine Cummins replacements.

The next item that needed attention was the turbo. It had lost it's thrust bearing causing the compressor wheel to get cozy with the compressor housing. That required another significant outlay of cash, this time to the local turbo parts shop:

As my wallet gets bled dry I keep telling myself "This is fun!"

Stay tuned for the next episode called "Ramen noodles and Cummins mods"...