The next problem to solve is the fact that the speedo housing on this 205 is for a cable speedo, and my truck has an electronic speedometer. Electonic speedo housings for the 205 do exist, but they are rare as hen's teeth. They were only made in 1990-1991, and only in 1-ton crew cab pickups. In other words, they are impossible to find, and if you do you'll pay dearly for it.

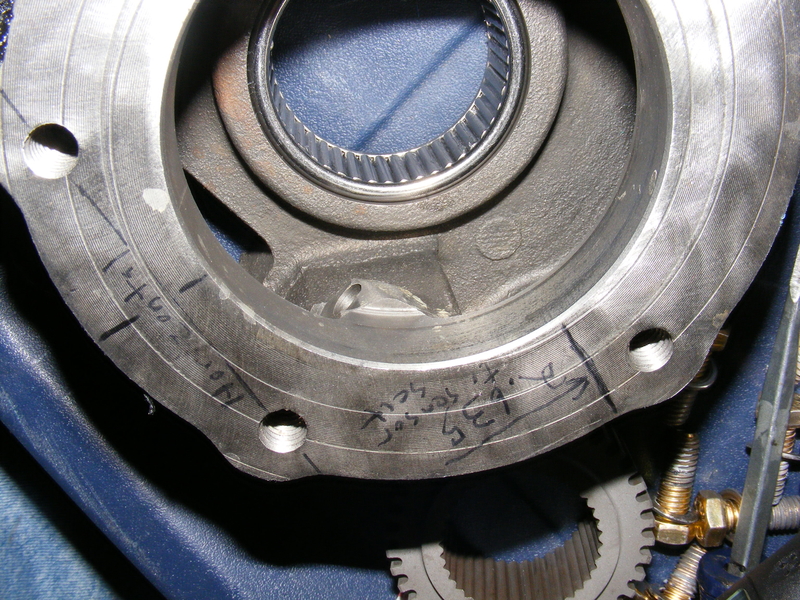

Once again, I had options: Either use an electronic speedo pickup that threads into the cable speedo drive, or modify my housing for a VSS and replace the speedo drive gear with a 40 tooth reluctor. I chose the latter option since it is a bit cleaner. It involved marking the housing with dimensions using a Sharpie, and giving it to Todd to drill, counterbore a flat seat, and tap for the VSS:

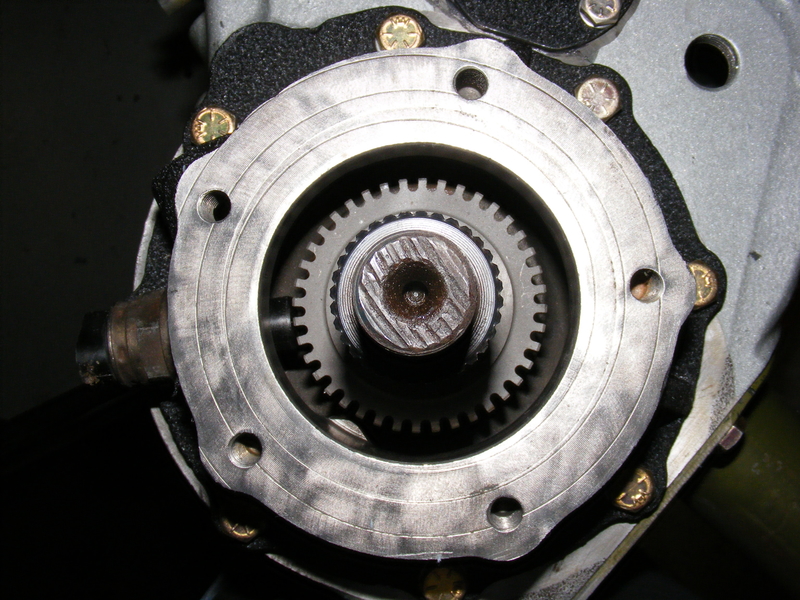

As it turns out, the speedo gear/reluctor splines on the 241 are the same as a 205, and I just happened to have a 241 reluctor. It's wider than the 205 gear, so I turned equal amounts off both faces until it was the same width as the 205 speedo gear. When I went to assemble it I found a cast boss in the housing hit the reluctor, so I had to use a rotary file to cut away the tip of the boss. Here's the result:

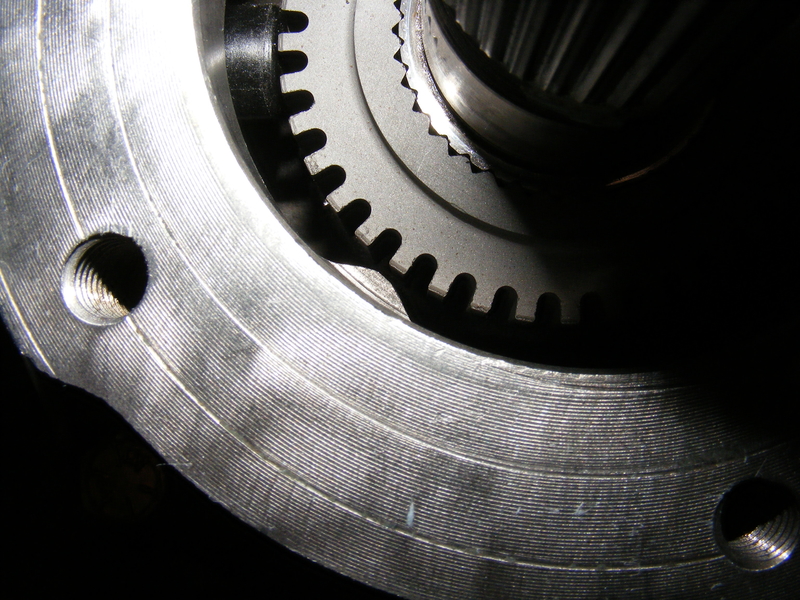

This is the boss I had to cut down:

The finished product:

In that last pic you can see the hole where the cable speedo drive threaded in. I have the piece that screws in there, and I welded a -6AN male fitting to it and put a cap on it. It makes an excellent fill port for a clocked 205, and it will serve another purpose...

Finally, I needed two other items to make the case ready to install. First was a spacer/clocking ring. I could have used the short 32 spline input and cut a notch in the 4500 tailhousing to clear the rear shifter shaft, but I didn't really want to. Plus, I wanted to clock the case up, and the ⅜" thick clocking rings usually used are prone to leaking. A spacer to allow use of the long input will eliminate the need to cut the 4500 tailhousing, and it is thick enough that it won't warp and leak. So, I drew it up on Solidworks, emailed Todd the file, brought him a piece of aluminum. It turns out the aluminum was a hair too short, so I TIG welded an aluminum bead around the pilot ring to give the needed extra material. If you look close you can see the where it was welded. Without that extra material the pilot was barely (like a few thou) too short when a gasket was used between the trans and spacer.

In that pic you can also see the second final item I needed: a linkage to actuate the rear shifter shaft. Once the case is bolted to the trans, that shaft is only accessible from the side, so a linkage is needed to hook up a shift rod or cable. The red aluminum Heim joint is where the shifter rod will attach. The linkage and bracket holding it are all stainless steel, so no paint is needed

That's it for now. On the next episode, I'm gonna get

dirty :wink: