Quote:

Originally Posted by 70custom20

Ryan, I have to agree with everyone else that those welds look absolutely great. Steady hand, right amount of filler wire on each dip, etc..... I do some Tig welding at work, I'm a Steamfitter (Pipefitter) most of the time I'm stick welding though. I have two welders at home, a Millermatic 175 MIG, and a Lincoln 175 square wave AC/DC that do a decent job for what I neex to do. I wish I was better at welding on aluminum, but I just don't do it often enough. I have been told that the newer machines like the Miller dynasty are a dream to weld with. Anyway, just when I think some of my freehand TIG welds look good, I look at guys like you and I'm reminded that I'm average at best.  Kurt |

Thanks! Fitting is an awesome craft. i enjoy doing fit up work as much as welding. it is nice to work something into just the right place. and its nice to weld it that way too. My stepdad is a union fitter. i dont think he does steam, but i really dont know.

i've heard the dynasty series is awesome too. i hope to test that myself one day, but for now my little everlast is doing its tricks. i decided to get the green one on the chance that i really didnt like the inverter. i do like them, but i am too new to them to feel as proficient as i'd like. i also shopped a little smaller than i will next time. this one is a 250A machine but pulse cuts the applied amperage down enough that i would like a bigger machine. other than that it does fine. i was burning 3/16 309l rods with it just to see how it stick welded and was pretty impressed.

my MIG is a MM250, i learned on that very machine in HS so i like it, but i really would like to get something a little different i think. the Lincoln 255s are nice, but the Miller 300xmt i mig with at work is by far my favorite mig power source that i could ever hope to afford as a hobbyist. i welded with an Axcess 450 for a while in my younger days and

that is Mig welder. but also $8500 or something. and way to big for a garage. But fun to play with.

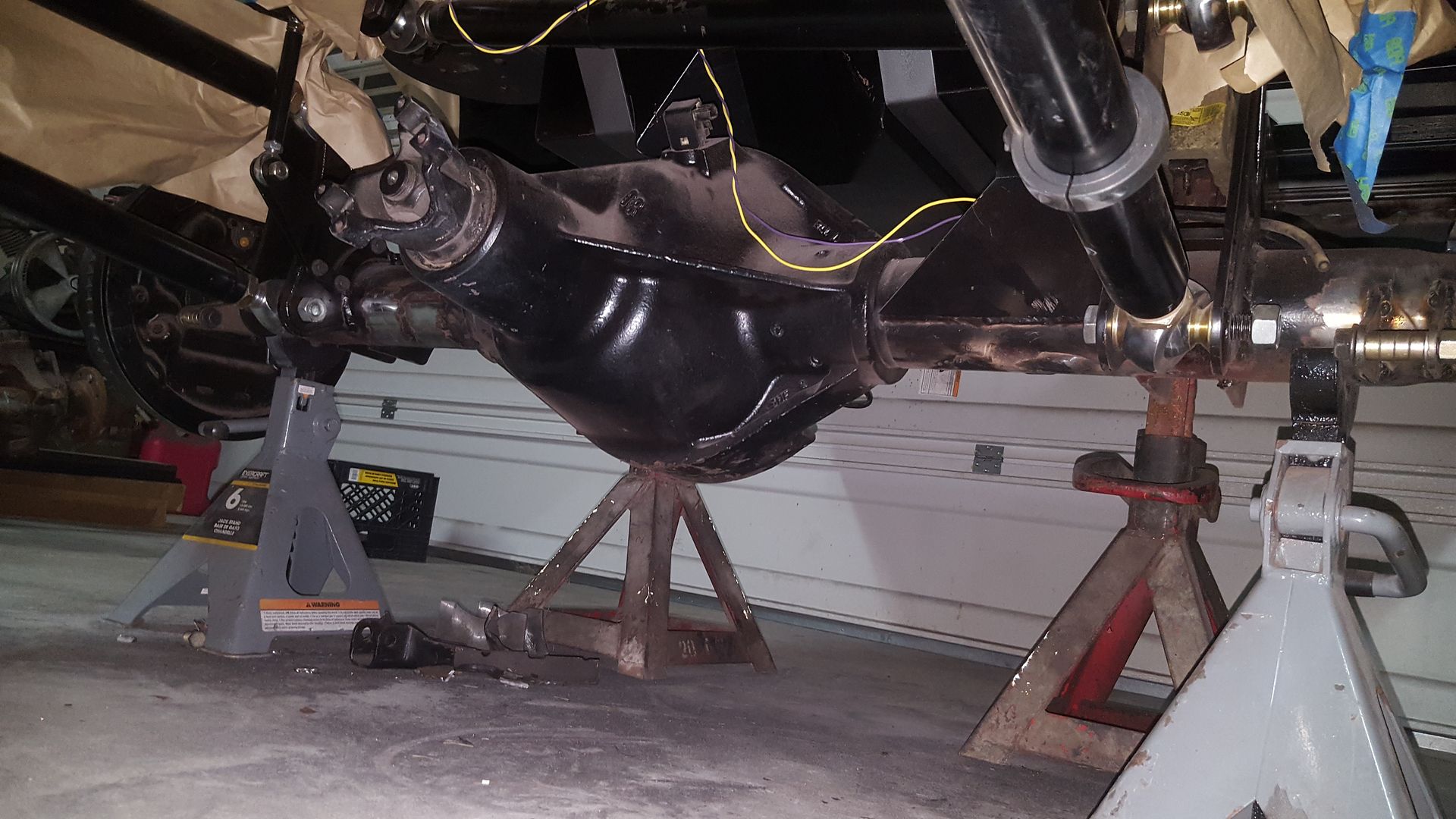

i got the rear limit straps installed.

the frame side

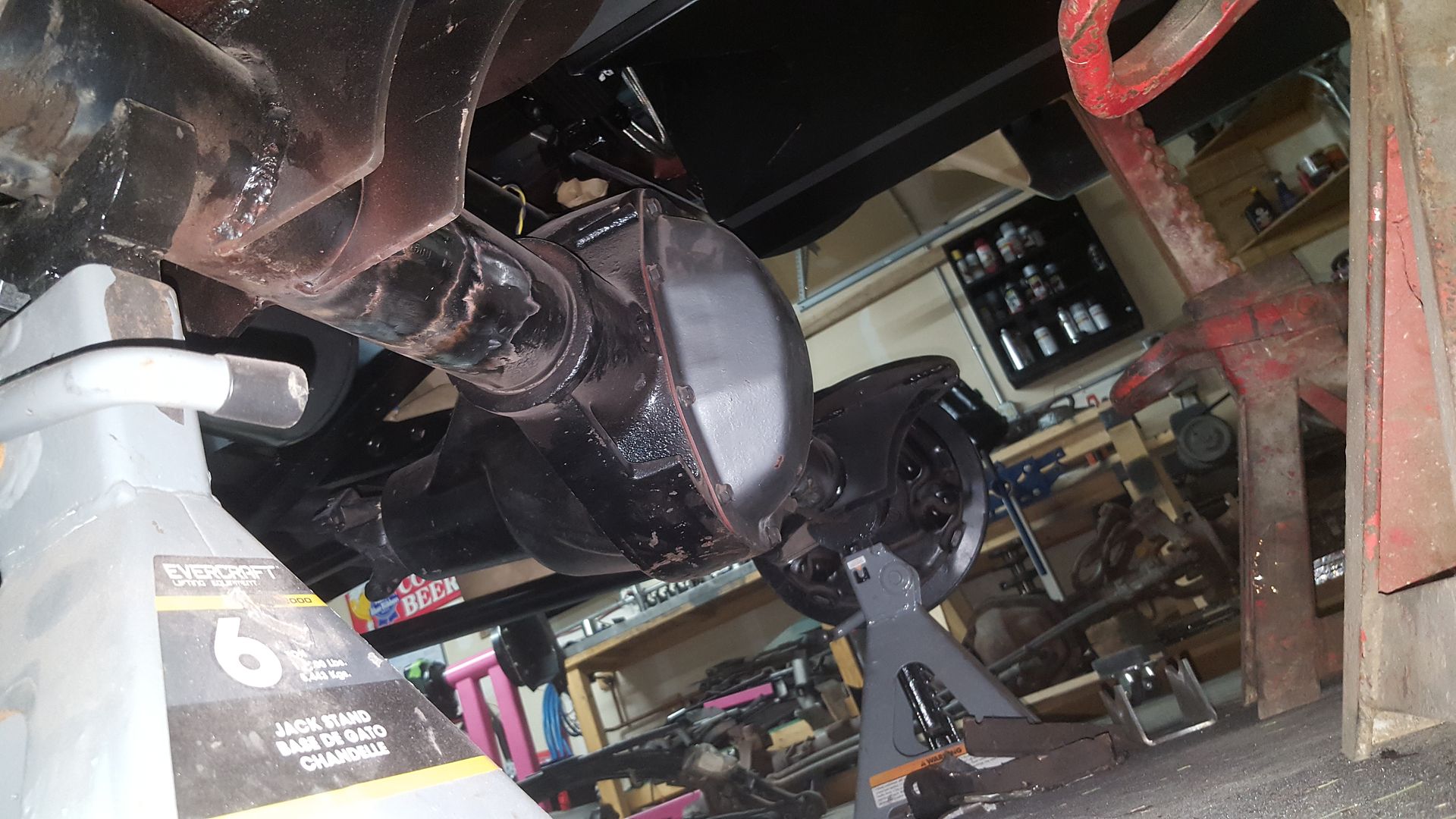

axle side.

the tabs are probably overkill at 3/16" thick. better safe than sorry, right?

welded the lower shock tabs at this time as well.

welded the uppers

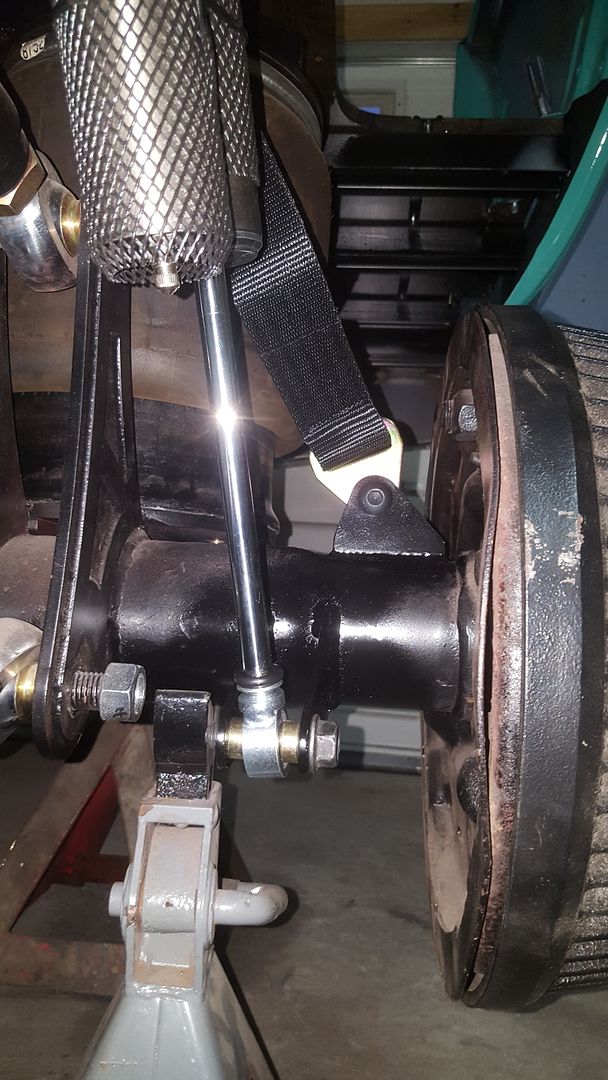

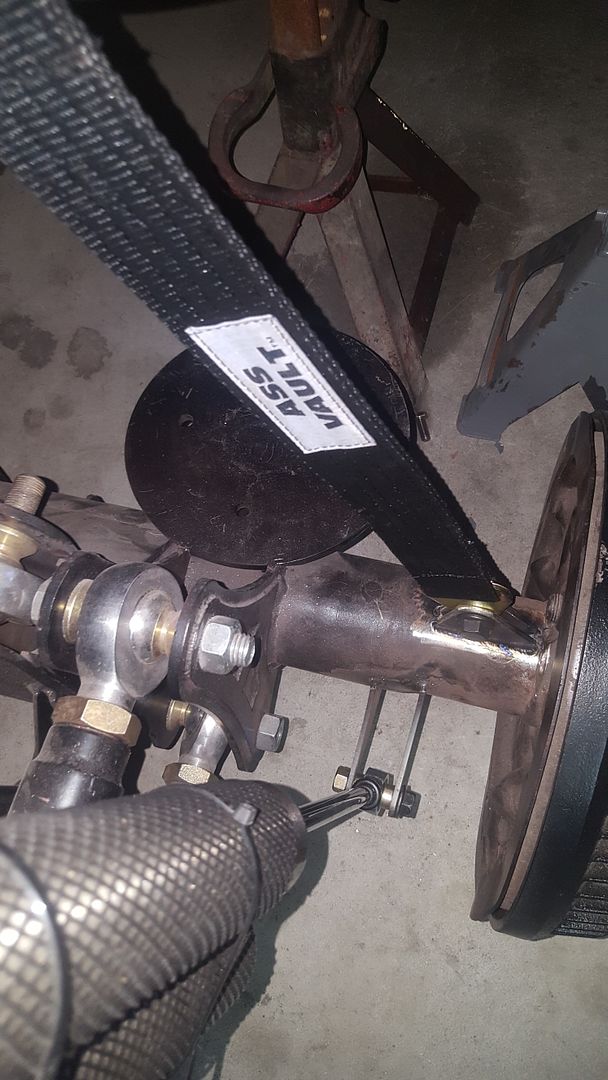

the straps from Ruffstuff are burly and fairly priced, and they come with a comical tag

painted the upper shock mounts too.

a way long time ago i was going to try to incorporate the dodge shock mounts on the axle. that died a long time ago, but i just ignored them. i finally got my crap in a pile and ground the ugly SOB's off. looks better than i figured it would