Made some good progress in last week or so...90% of the suspension is done, interior gutted, firewall mods near complete, clutch master cylinder is near done, waiting on parts to arrive to complete some other stuff, and cross member/mods done.

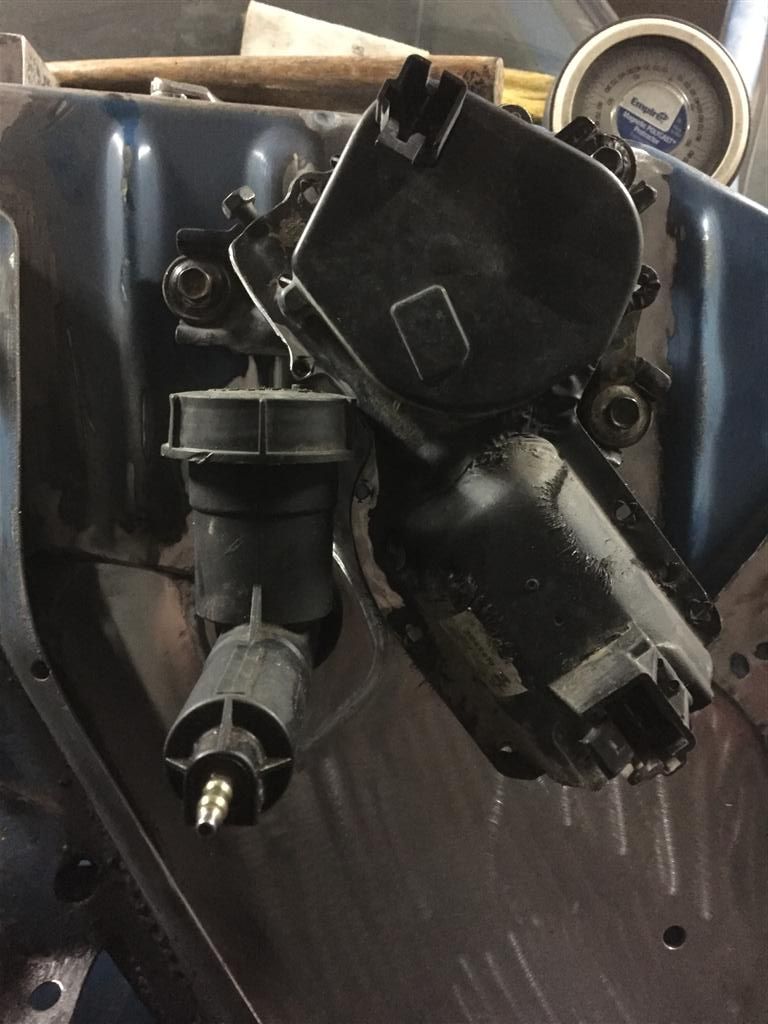

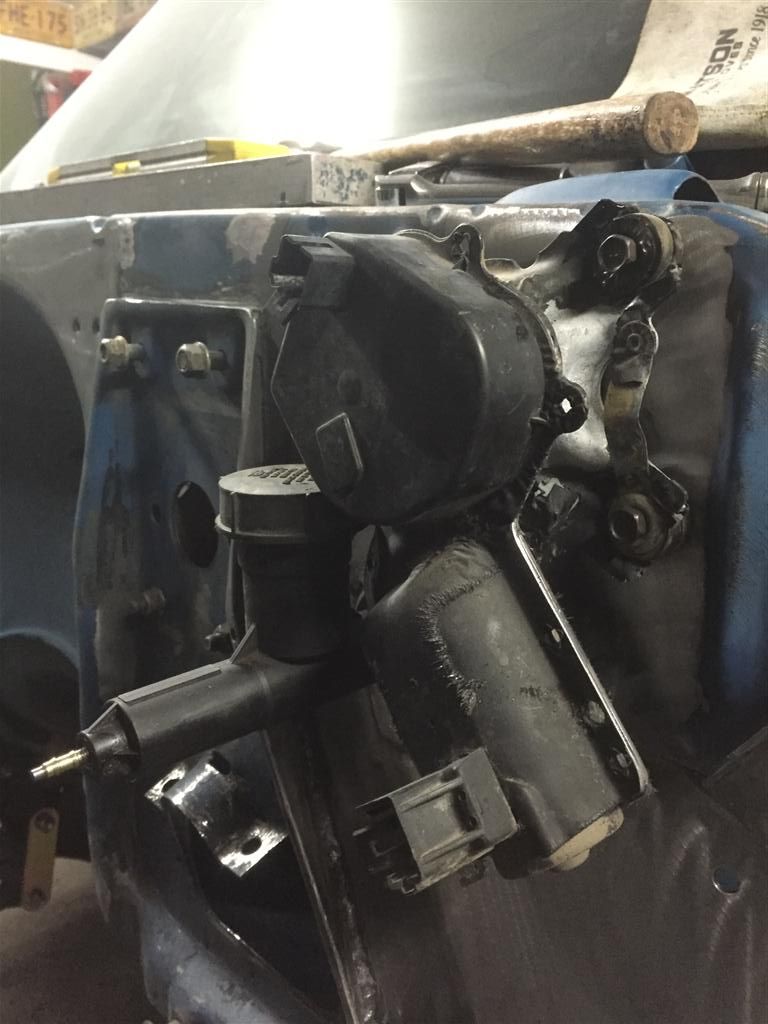

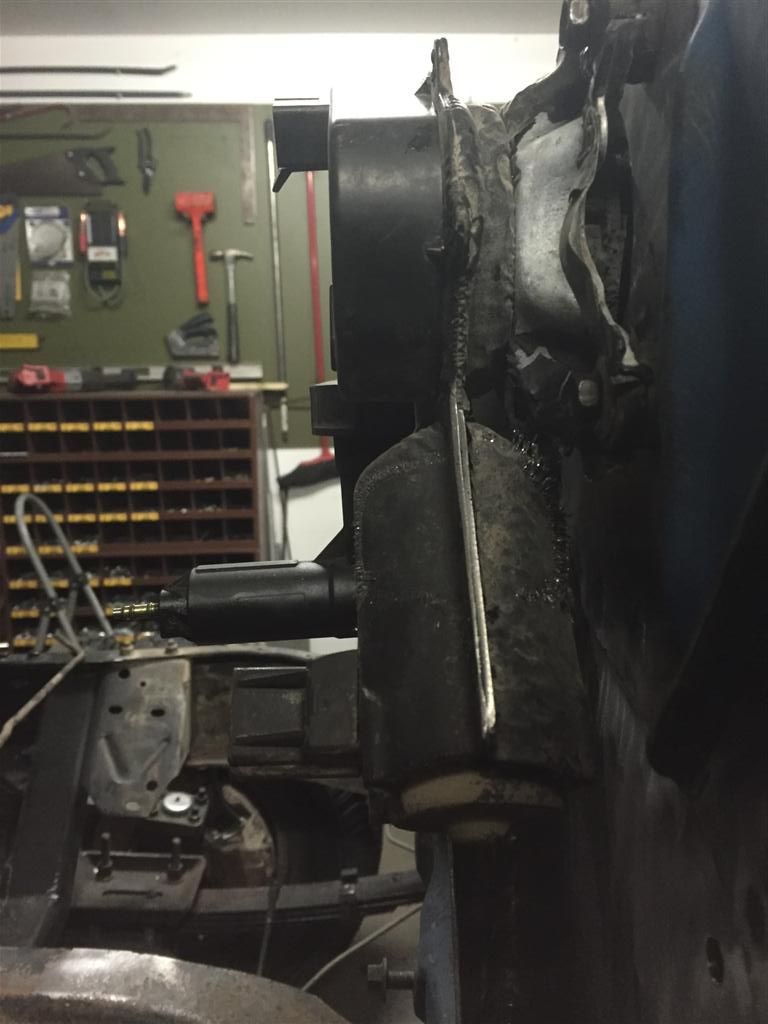

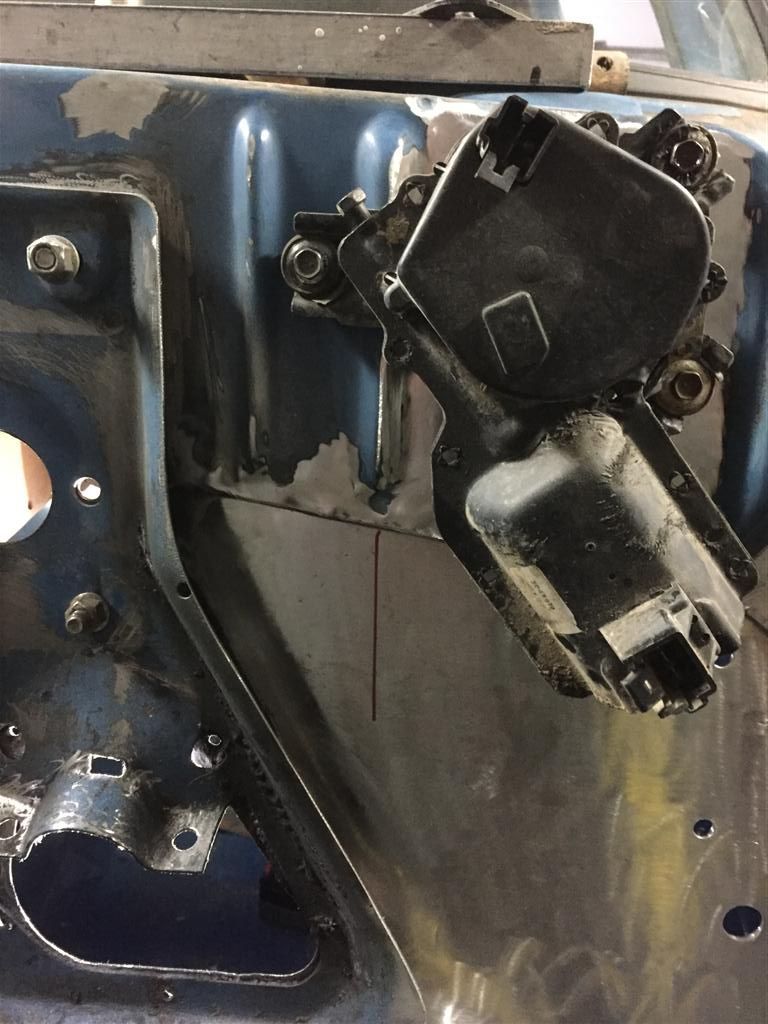

Clutch master cylinder was donated by a 1995 F250....benefit: a lot lighter clutch pedal, because it's a bigger bore, but not to big to over extend the dodge slave cylinder, or make the engagement location to touchy. Along with this the fire wall may not to be strong enough and will eventually crack/fail over time and usage. So I chopped out the area where the fuse block and master comes through the firewall and spliced in some 3/16" plate to help out the situation. I ordered a new wiring harness anyway, and this cleans it all up/gets rid of all the crappy looking holes that are no longer going to be needed. As you can see in the pics, the clutch master cylinder is ridiculously close to the wiper motor, this being that it was mounted as high as possible to attain as much of a straight shot to the master cylinder/rod/pedal assembly to avoid premature wear on the seal inside the master. They don't like much side load and may fail sooner than normal. Ended up with 2* inside and 2* on the master in relation to the fire wall so we should be gold on that. This master cylinder also rotates when mounted around 2" counter clockwise, so fluid level top ups/checks are easily attained regardless how bad it looks.

Also went and filled in nearly all the swiss cheese holes in the firewall....GM must have had a competition to see how many useless holes they could put in here...just cause. Not going to spend a pile of time smoothing it out, but want to get a reasonable decent look to it before it gets hammered with soundproofing and bed liner. Clean and simple. Trimmed up a few pieces on the firewall as well...here and there, rolled the firewall seam for transmission clearance.

Cab floor or even as a whole ended up much better than I had expected...floors are near mint. Some light bubbles showing but clean steel underneath when hit with a flap disc really quick.

Still trying to decide on a color for it....not looking for a high maintenance color...so considering possibly a silver or green. Interior is going a two tone grey/charcoal so either would work I guess. Motor/trans/tcase is more than likely going Cummins tan...Seriously considering doing a color matched bedliner throughout the truck...inside and out. Have a design in mind to make it stand out somewhat and still keep it very much the work truck/head turner/daily driver I intend it to be when completed.

Front brake lines end up being 2wd versions with the mounting tab removed, and adjusted hard line at the caliper. More than long enough for a driver plus some. Going with the setup I have, then using a braided line....tends for a very touchy pedal on some applications so decided to keep it simple with stock parts.

Tons of pics to update....