I posted this over in the "Make it handle" thread, but I'll post it here too to keep everyone up to date.

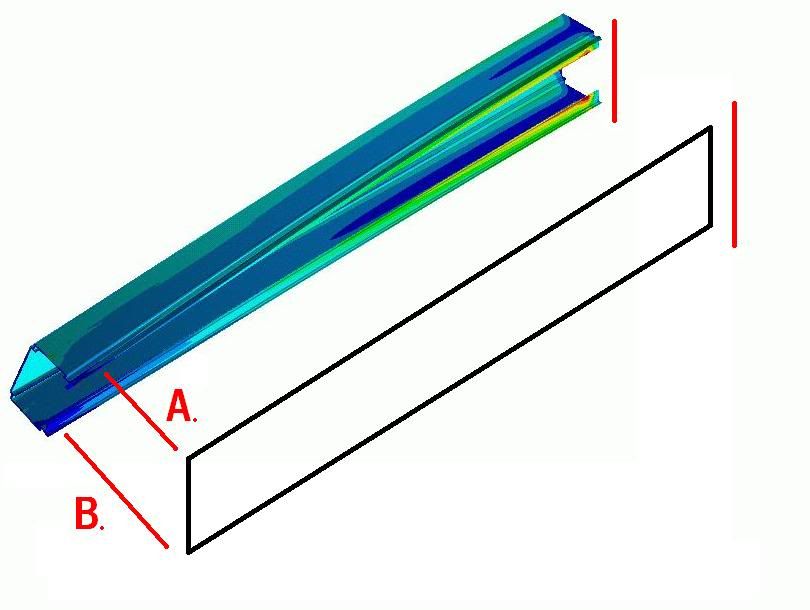

The distance between the upper and lower sections of the frame C channels changes as the frame twist. An upper and lower X member will tie the top and bottom flanges of the C channel together and won't let the distance between them change. If I just made a single layer X member and welded it in the frame rails, it wouldn't hold the frame rails from spreading top-to-bottom.

I made this drawing in paint to show how the distance between the frame rails change as they twist. Notice how distance "A" is shorter than distance "B". Just one brace in the center would still allow the frame to pivot around that one brace, no matter how strong the brace is. Upper and lower X members with triangulated vertical bracing in between should lock down the distance of the rails, keeping them from twisting.

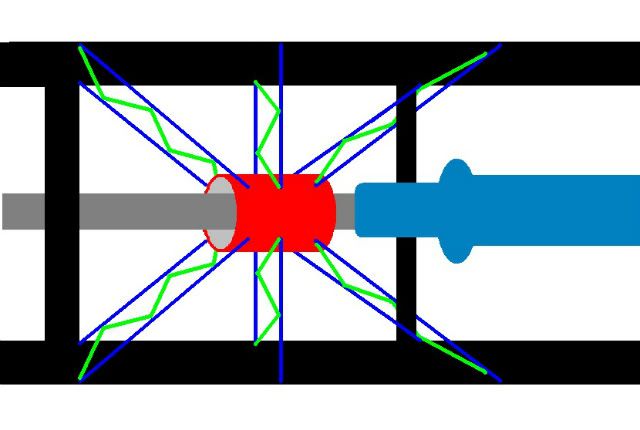

This is sort of what I'm planning on building, just not in such bright colors.