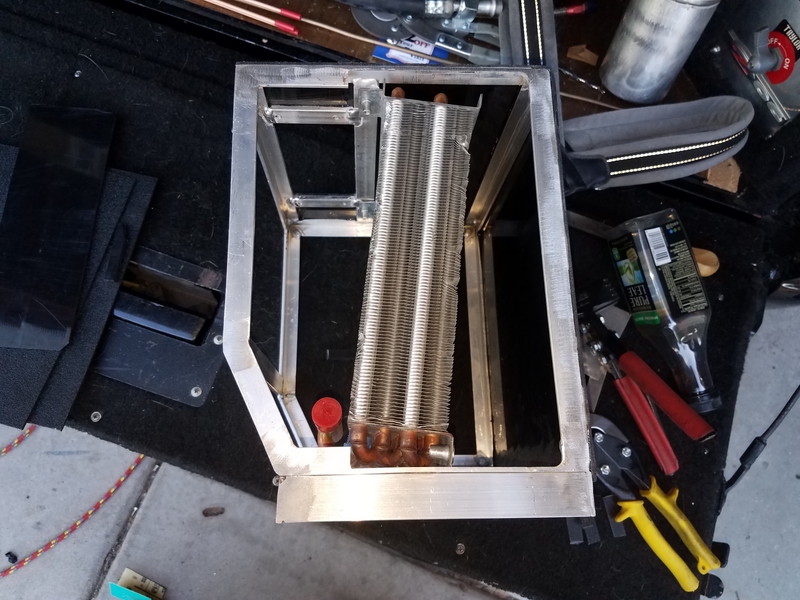

Still working on the evaporator housing. I made a few mods to the initial design. I found that mounting the evaporator at a slight angle gave an increase in room behind the evaporator for the expansion valve without reducing the outlet area, which is A Good Thing™:

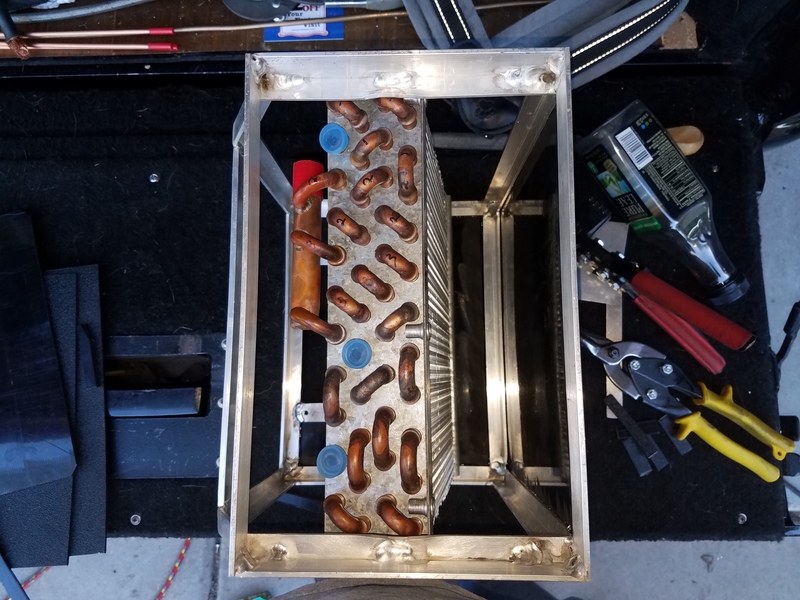

Here's a view of the firewall side. On the bottom, which is actually the left side if you were viewing it installed in the cab, you can see the outlet extension. This is what the housing containing the heater core and distribution doors will slide onto:

Top view. You can see that I already have ABS glued to the front and right side:

This is a view looking into the outlet extension. The face of the evaporator on the right is the outlet. The end of the evaporator will be covered by more ABS and will be on the inlet side. The little blue caps cover the open tubes where the three distributor tubes will eventually be brazed. The black crud in the corner welds is where I dipped the tungsten into the weld puddle because I was welding by sense of smell at that point

I have discovered that welding is a perishable skill. If you don't do it often you lose the muscle memory and your skills deteriorate. Unfortunately, so does your eyesight as you age. My welding skills, especially on aluminum, used to be MUCH better than they are now.

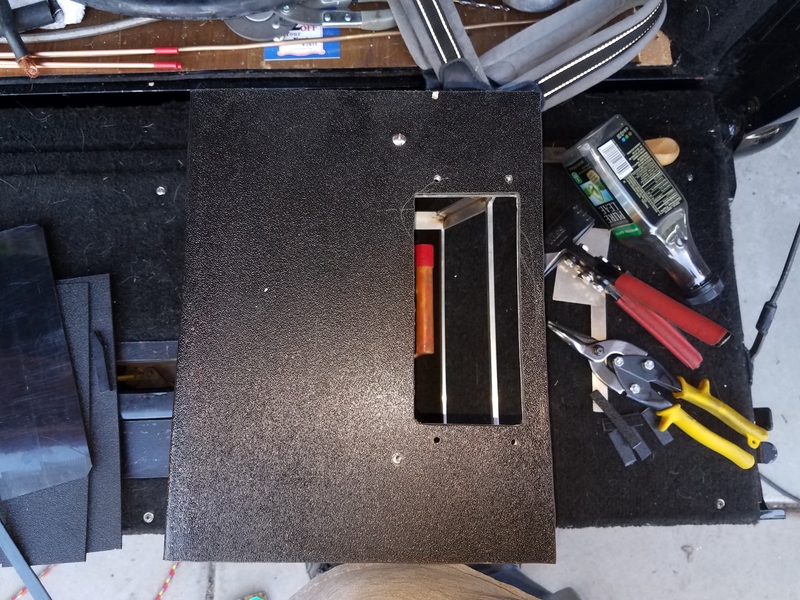

This is the right side. The square hole is where the blower blows into the housing:

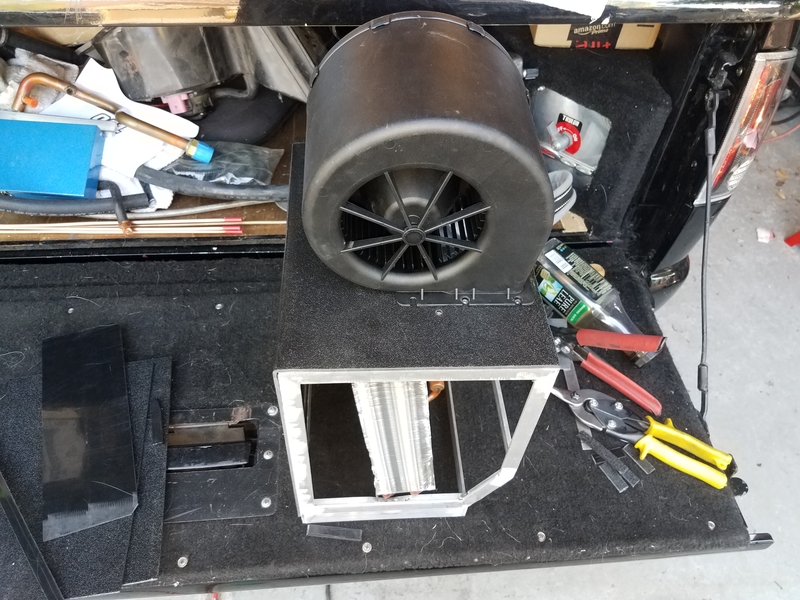

What it looks like with the blower in place:

I now reached the point where I needed to glue two more ABS panels on before I can proceed further, so as of tonight it is sitting with panels clamped in place letting the adhesive fully cure overnight:

This is the adhesive I am using. The place I buy from has a good assortment of products by 3M, Norton, and SEM. Of the products, this one was recommended by the manufacturers literature for bonding metal to metal, metal to plastic, and plastic to plastic. It's a 2-part urethane adhesive. It's not as strong as the epoxies, but the epoxies weren't recommended for use on plastic:

After I glued the first panel on and let it cure overnight I tried to rip the glued seam apart and it just laughed at me, so I think it is strong enough for an AC housing

I also got a tube of moisture-curing urethane seam sealer for sealing gaps and especially for sealing the condensate tray. It's half the price fo the two-part urethane adhesive and thicker. I don't want air leaks, and I really don't want a condensate leak!

That's it for now. Stay tuned for the next exiting episode!