OK, so I got axles in, Yay... But I still can't even roll the truck forward because I don't have a tie rod to keep the front wheels straight. Well, remember those built-by-Todd parts in the cardboard egg tray in the previous posts? They just happen to be ⅞-18 right and left hand tapped bosses for building tie rods, drag links, and Panhard bars. I combined one right and one left with a suitable length of 1-½ .120" wall 4130, some TIG welding, a coating of wrinkle paint, and some tie rod ends from Parts Mike end ended up with this:

Now that I had a rolling chassis again, I could address the next item: a transmission. I was originally going to run an Allison, and even had one built and ready to go, but I sold it to someone who needed it worse than I did. Then I brought home an Eaton-Fuller FS-6406. I got it for a good price, and planned on throwing OD gears into it, but it was just too much trans for a Blazer. A one ton truck that tows a lot (and routinely breaks NV5600s and G56's), yeah it's the hot ticket, but a 365lb 6 speed is just too much gearbox for a K5. I would have to substantially surgically alter the floor and firewall to accommodate the trans, and i just didn't have it in me anymore. So I sold it off to a guy who actually needs it for his dually on 37's.

I still needed a trans, and there was only one practical choice. The problem is, I don't like it. I'm talking about the NV4500, and anyone who knows me knows I hold this trans in very low regard. The first through fourth gear portion is decent enough (although the 465 is better IMO), but fifth gear is a complete crap design, and the gearbox has smallish countershaft bearings. OTOH, it can be fixed up and it has the OD I need, so it's what I ended up with if I ever want this heap to roll under it's own power again.

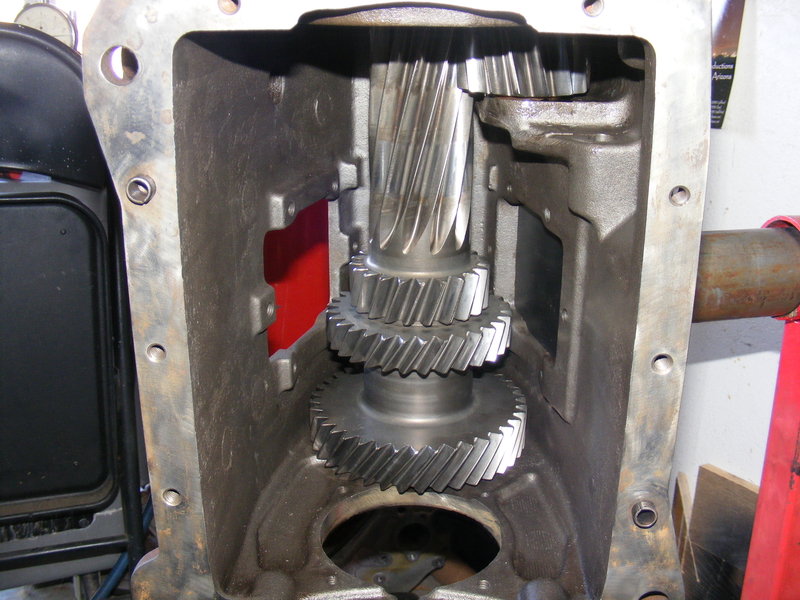

Because I wanted to run a round pattern 205 that I already have, and it has a GM bolt pattern and GM 32 spline input, I chose to run a late GM NV4500. Parts are interchangeable with the Dodge version, which allowed me to run the aftermarket 1-⅜" input shaft designed for hot-rodded Cummins apps. I found one for sale from a guy on 4BTswaps for a good price. It was out of a 350 Vortec truck, so it had no mainshaft damper but a spacer sleeve instead. Not a big deal, but the damper was put on the units that went behind the 4.3 V6 to keep gear rattle down, so I expect I may end up with some gear rattle. We shall see. Anyways, here's the trans in pieces:

If you look at the following pic you will see that the end of the countershaft has 16 wide-spaced splines in it. The shaft can accommodate 48 splines that size, but New Venture chose to only run a third of the maximum. Why? I dunno. SInce the input-to-countershaft multiplication is something like 1.8:1 there is a LOT of torque applied to those splines when at full throttle, even in a gas motor. That they survive at all is a miracle.

Usually, it is the mainshaft gear that has issues. It's small and retained with a spanner nut. Over time the torque can work the gear back and forth, eventually working the nut loose. The nut backs off and the gear follows it, walking off the splines. There are numerous fixes, but my favorite is

this. Unfortunately, they only make that lock for the Dodge 29 spline shaft, so I used a piece of female 32 spline input that was cut off of a NP241 and a piece of chromoly tubing with 4 tangs cut in it, welded it together, and made my own.

The 4500 does have one outstanding feature: good synchros.

Those fiber-layered rings make the synchros work way better than older grooved brass synchros in transmissions like the 465. The only drawback is that they work best with the special fluid made by Castrol with costs $20 a QUART! And the trans holds a GALLON! Since the trans doesn't oil well with only a gallon it is recommended to put 4.5 quarts in it, so I was forced to buy 5 quarts. Did I mention it's $20 a quart? Yay....

I did need two new hard parts though. The synchros in third were completely wasted, and the owner obviously kept grinding it to find it. This destroyed the 3-4 slider and the coupler splines on the third synchro hub. I was lucky that a fellow wheeler had a good assortment of NV4500 parts on hand and was able to hook me up. Other than that the trans was in very good shape. I was even able to re-use the bearings, although how long they will last behind a Cummins I can't say. I did put all new synchros in the trans, of course.

Eventually I got it all together:

Those with sharp eyes and familiar with the NV4500 will notice that the bolts retaining the aluminum tailhousing aren't the stock 12-point New Venture units. I managed to windmill the head on one of them, and the rest were a bit sketchy. Regular 6 point bolts don't leave enough clearance for the socket, so I used metric Allen bolts instead.