I promised plumbing, so here we go! I already mentioned that I moved the fuel lines to the drivers side frame rail due to the fact that the exhaust runs down the passenger side, and the lift pump is located on the drivers side of the engine. Likewise, I decided to relocate the brake lines to the drivers side frame rail

I would have preferred to use stainless steel for the brake lines, but it requires expensive tools to double flare, so I chose to use cupronickel line instead. Cupronickel is typically 90% copper 10% nickel, although I have found some alloys that also included iron. In any case, the purpose of the nickel is to prevent the copper from work hardening and cracking. OE's used the stuff many years ago, but they went to steel due to cost..

Anyway, I am using the same 1 ton master cylinder and hydroboost that I had on before. I eliminated the stock prop valve/RWAL unit because it didn't proportion properly with rear disk brakes. I replaced it with an adjustable unit from Wilwood, mounted to a custom bracket:

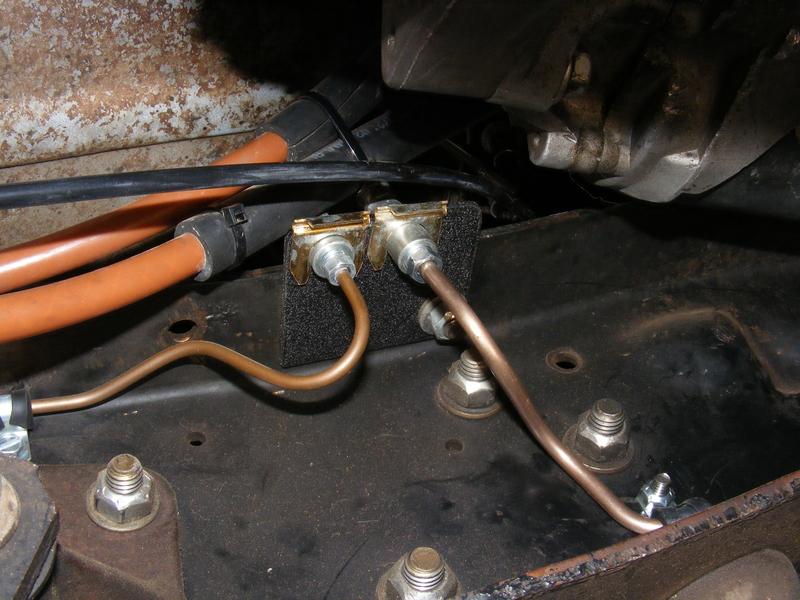

The hard lines run down the firewall, then transition to a pair of Teflon soft lines to bridge the body-to-frame gap. Here is where the hard lines reconnect on the frame side:

The line on the left is 3/16" and goes to the rear brakes. The line on the right is ¼" and goes to the front. The 3/16" line had to pass through the boxed section of frame, but there was no way to clamp it in there and it was too long of a span to have unsupported. I solved the problem by running it through a piece of ⅜" stainless tubing with flared ends (to avoid cutting into the soft cupronickel) and supporting the more rigid stainless tube at both ends:

Bracket that drops rear Teflon line to the axle:

Up front, the ¼" line heads to a tee on the front crossmember. You also see the 3/16" line feeding the drivers side caliper, with plenty of Adel clamps retaining everything:

Tee on front crossmember with 3/16" lines heading off to each front caliper:

Caliper hoses are new. I used Teflon brake hose rather than rubber:

I also got vent lines hooked up. I used ¼" air brake line for the vent tubes and connected them with either AN fittings or, in the case of the transmission and axles, using an intermediate rubber hose:

So that's it for now. Nothing exciting, but it's amazing just how much time this all takes...