I was trying to figure out how I was going to build the fuel system for this truck. I had the tank, pump and hoses from the donor truck, which would have been awesome to use. While the tank is similar in length and width, it is about 4-1/2" taller, which would make it hang down under the bed too far, so that idea was scrapped.

The original 16 gallon tank is a bit small and was corroded pretty bad on the outside. I had a 20 gallon saddle tank and I could use it as is with an inline fuel pump, but it would be kinda noisy and it's not baffled inside to keep fuel around the pick up tube, which isn't a huge problem when you're running a carb with float bowls to hold fuel, but is a problem with EFI.

So I'm going with a new tank for an 87 but will get an aftermarket pump for the 60 psi needed for the LS. BTW, the TBI systems run at around 12 psi so the stock 87 style pump wouldn't work. It bothered me to not use parts I already had though, so I came up with a plan to use the old saddle tank as a reserve tank. The low pressure electric fuel pump that used to fill the carb will now be used as a transfer pump to the main tank. So if fuel is getting low and I don't feel like stopping I can flip a switch and pump gas from the passenger side to the driver side tanks. I could put a full dual tank set up but that would cost quite a bit more to do and isn't really needed.

Aux fuel tank...

One of yesterday projects was taking out broken exhaust manifold bolts. One was sticking out far enough to get a vise grips on it and was easy to pull. The other was broke off about an 1/8" inside the head and has been a tough mother to fix. I tried welding a nut, but it wasn't working. These are fairly small diameter and the weld just kept jumping to the side and not sticking to the bolt. Then I tried drilling but wasn't getting the center. So I used the manifold as a guide, but the holes are much larger diameter than the bolts so you can't use it as a guide as is. I found a 7/16" bolt that fits the manifold hole tight, cut off a piece and drilled that centered to use as a guide.

Still not done though. It's kind of a PITA because you have to drill the plug out to size for each stage then drill the head. As the bits get bigger, they also get longer and even with my angle drill head adapter thingy I'm running out of room. You may be asking why I didn't fix this BEFORE putting the engine in and that is what I keep asking myself while dicking around with this.

Anyway, I'll probably have to drill and tap it out to the next bigger size.

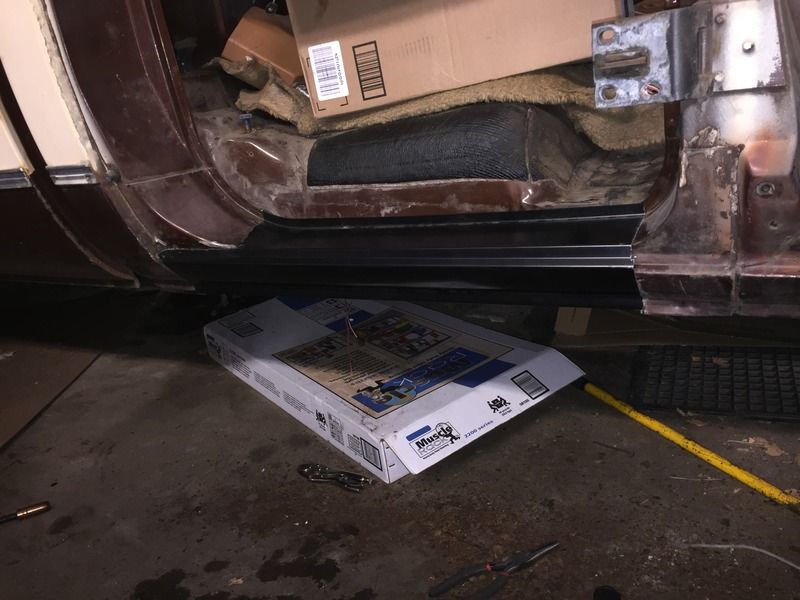

While I was doing that, the boy started doing rust repair. I think he was hesitant because he doesn't have much experience. Went to school and is working in a shop but not really cutting and welding much. So I'm guiding him from my vast experience (only slightly more than his

).

The front rocker is cut out...

The rear is cut out and the patch is starting to get fit into place...

I should be picking up the new tank this week. I'll hopefully get the broken bolt fixed tonight, but might have to pull the engine at least part way out to fix it, or cut off a drill bit shorter. I need to get some inner rocker patch panels and another pair of outers.

Next unsolved mystery is the AC pump. I have a pump but no bracket. And from what I've read the truck bracket probably wouldn't work anyway.