if you turn this air cooler 90* and hook the compressor to the top you can get away with using one drain at the bottom

copper will cool better than black pipe and go together quicker, but black pipe will cool well too

unless your doing a commercial shop, 3/4 anything is big enough, my shop is all 1/2'' copper

the drops should come out of the top of the header. ''T'' up and 2 90*s to turn down

a ''T'' down will allow dirt and moisture to run down your drops

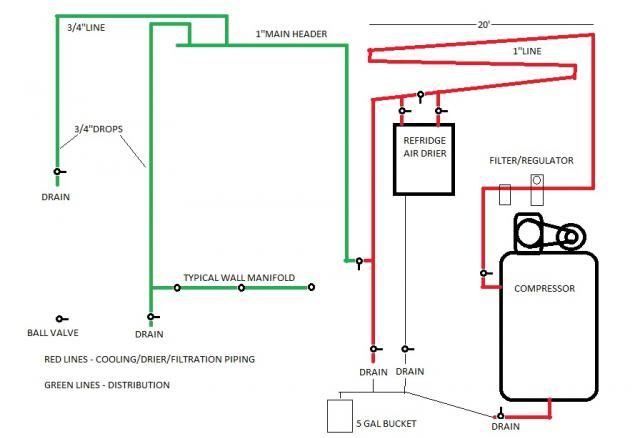

here is how i ran our commercial shop; 3 lifts, paint booth, cnc plasma table and 6 guys using air tools

1'' black pipe for the main header, 3/4'' copper for the drops

the cooling loop is 30 ft of 1'' black pipe anchored directly to a block wall, we also run a air dryer