Lots has been said about heater cores, but I haven't seen a write up on replacing one, so here's my abridged version:

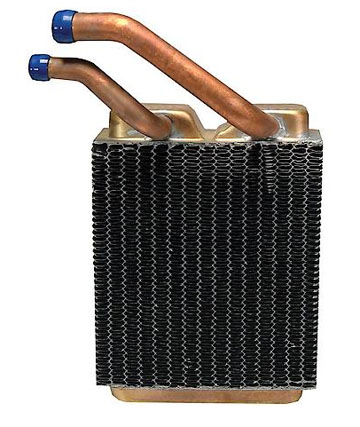

Purchased my core from Advance Auto, it's now in my '64 C10 with Thrift Air. It's not as tall, but width and length are the same. The tubes that connect to the cooling system are a little low and I'll cover that later.

The large bolts in the engine compartment aren't the only ones that hold the heater box in place, there's 2 hidden on the cab's firewall behind the glove box. One is easy to get to, the other can be reached if you have a good collection of extensions for your socket set, just need to maneuver the socket between the heat vent box and glove box cardboard. If you have firewall padding, you'll need a deep socket to get to them and be careful not to lose a nut inside the padding or you can kiss that baby goodbye. On the inside of the cab, there's no need to undo the 3 bolts where the heating system and the heater box join just under the glove box.

The nut on the left is one of the two from behind the glove box and it's stamped steel. I find them to be a PITA for a few reasons, so I purchased washer nuts to replace them.

Once you have the heater box off, take off the tiny bolts that holds on the lid, there's 2 C clamps holding the heater core in place. Although the replacement core isn't as tall, it still was a good fit when the clamps went back on. I've read that installing the larger Deluxe Heater core in a Thrift Heater can be an issue due to a plate inside the box, but maybe they stopped putting it in around '64 or the Baltimore plant didn't use them because mine didn't have it.

After putting the new core in and reassembling, I found that the bracket on the outside front corner that supports the tubes that connect to the cooling system was too tall, so I fashioned a replacement bracket by heating some scrap steel and shaping it around a large lag bolt. It's not as rigid as the original one, but it works. I wouldn't put it back on without some type of support, one wrong move and you could snap a tube off where it's soldered to the core.

That's all the stuff worth mentioning, everything else was a piece of cake. I'll let you know in a few months if my cab is warm for winter.