Thanks guys!!

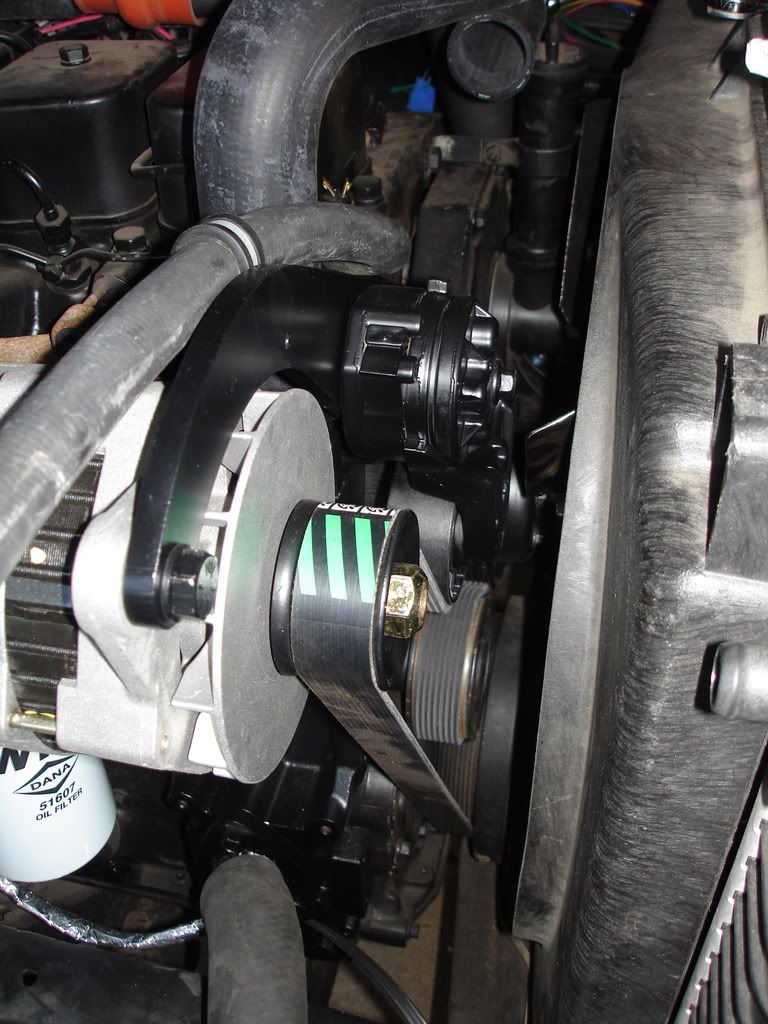

I have been getting more done lately, just not had the time to post pics. I tore the brackets and what-not off of the front of the motor and got them painted up and re-installed:

I got my heater supply hose figured out. With the Adel clamp supporting it, it clears everything nicely (it doesn't look like it does in the pic though)

I figured out my lower hose. It fits good, but the pic makes it look like it is sitting on the inner fenderwell. It actually clears by a little bit, but will probably make contact at some point, so I added the anti-abrasion sleeve for good measure.

I finished up the harness off of the Horton fan clutch and added an anti-rotation device. Nowhere in the instructions did it say that one was required, but I did not want to rely on the shear strength of a couple 16ga wires to keep it straight, so I made one of my own. I also added a .125" steel rod to the harness to prevent it from being sucked into the fan.

In this next pic you can see the mounting point for the Horton harness on the outside of the fan shroud. The Adel clamp holds the harness nice and tight and with the .125" rod in there it should be good to go. I got the upper hose done also. I had to do it with two hoses for a couple reasons. The combination of the water outlet housing I used pretty much eliminated the use of an off-the-shelf hose and when I modified the intercooler pipe, I got it just a bit too long on the intake end and it interfered with what would be a stock hose from a Dodge, so I had to piece one together. It worked out pretty good as I am able to use two of the same part number hose which is a typical generic 90* hose, so availability will be good when replacement time comes. I used a piece of 1.75" tubing to connect them. I welded a bead around the ends for hose retention and added two support rods that go down to the cylinder head. I did not any of the rod that I thought I had here, so I ended up using two pieces of .625" solid bar stock. It's a bit heavy, but it won't break and at this point, what's a little extra weight??

I also got my battery cables made. This is the only pic I got that is decent enough to post. With everything being black, they just blend in. I used fine stranded 1/0 cable and put an old-school asphalt coated abrasion resistant sleeve over it for good measure. This is the driver's side battery:

I'm getting closer......