Thanks Jim!

More console work, time to fabricate the hemmed surround for the insert. In order for the surround to be seamless, we need to do some welding.

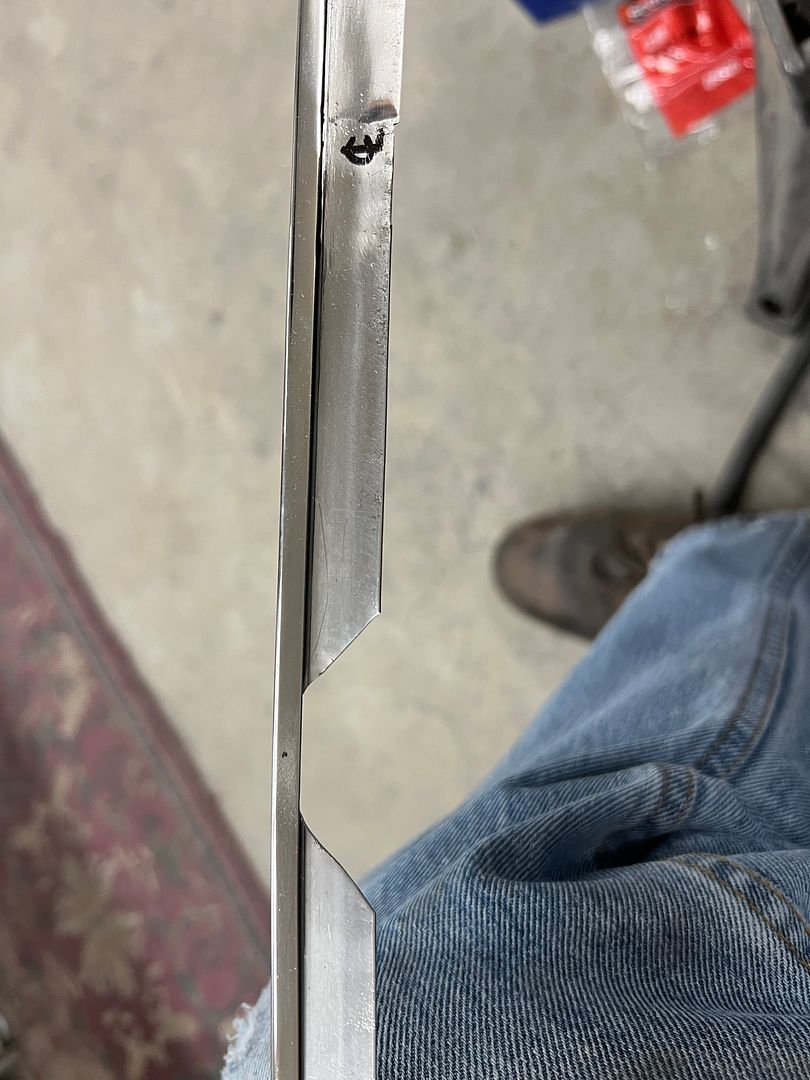

For our corners we relieve the flange and trim the back side to about half the hem width. This gives us less material in the tucks for shrinking in the corners.

We cut a fake insert out of 18 gauge CRS with rounded corners to use as a hammer form, gives us something to hammer against when we heat up the corners.

_IMG_8985.png)

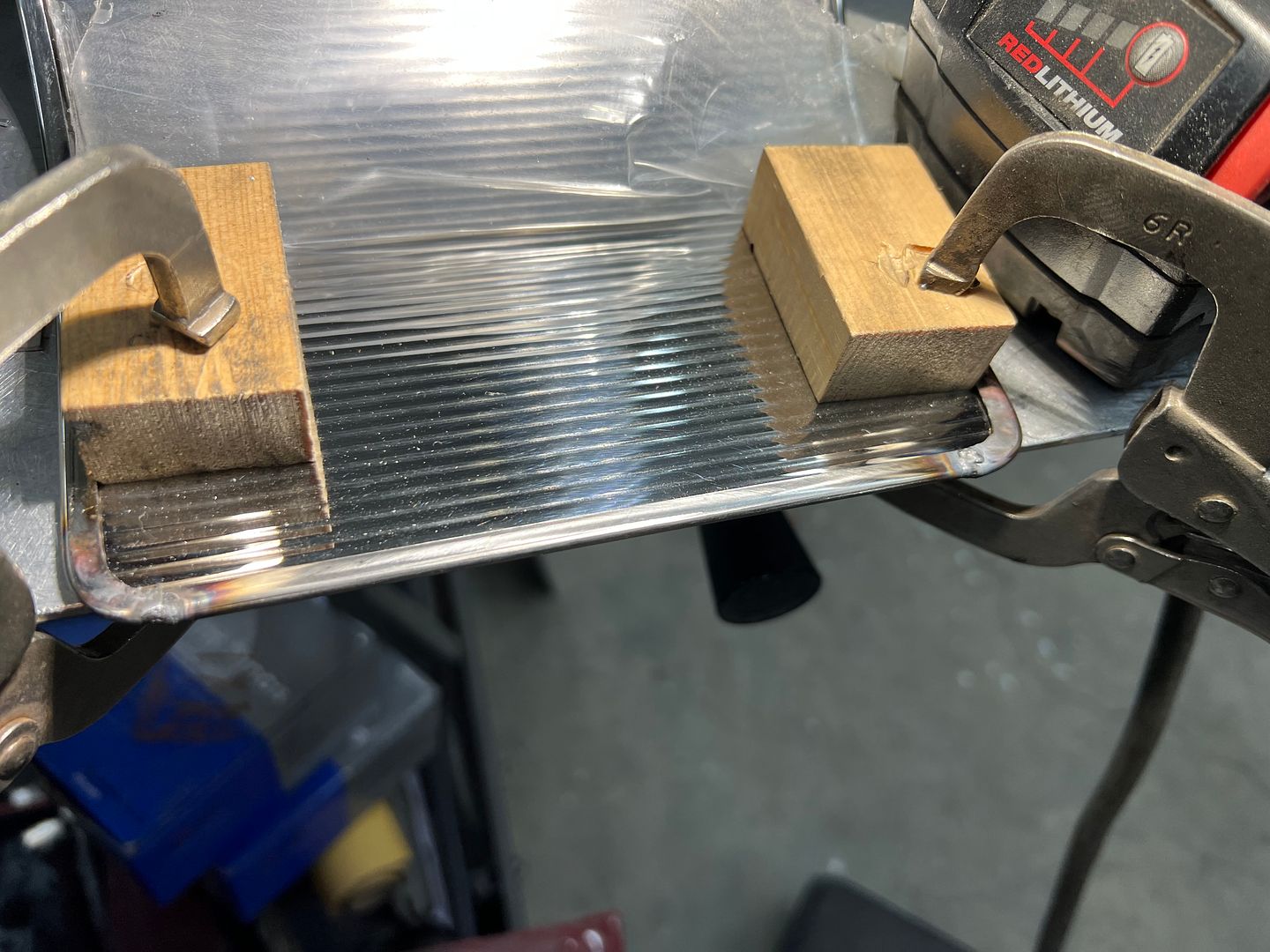

Everything's a tool, and when the PVC pipe is the only thing in the shop that matches our needed radius, it's what we use for a radius bender.

To prevent our hem from closing during the radius forming, some 18 gauge strips were placed in the hem.

Press studs used to attach to the console and will be hidden underneath the center panel.

Insert cut out to match our poster board sample, then it gets 800 grit, then 1000 through 5000 foam pads, then buffed..

https://youtube.com/shorts/Wlbrs908h...H0gssNlu9xhBkm

https://youtube.com/shorts/Wlbrs908h...H0gssNlu9xhBkm

Then we cover it with frisk film to protect our buffed surface.

Test fit...

Installing the surround to the filler panel

Still have to touch up some areas with the buffer (heat from tacking the press studs) but here's the test fit.

https://youtube.com/shorts/0FhzILNBY...Pzr-q_-0oYgu6S

https://youtube.com/shorts/0FhzILNBY...Pzr-q_-0oYgu6S

.