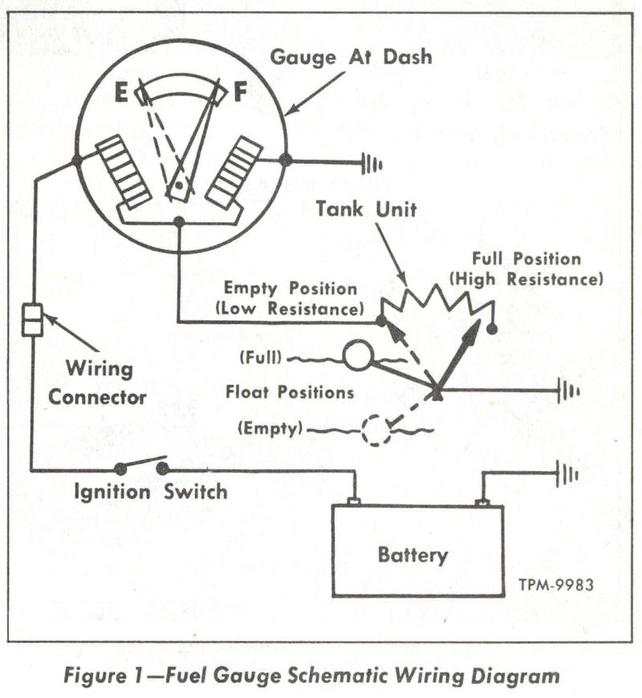

As you know the gauge reading is proportional to the resistance of the gauge combined with the sending unit resistance. That is, the higher the resistance, the higher the gauge reading and the lower the resistance the lower the reading.

This would suggest that either the sender resistance is not exceeding 1/4th of 90 ohms or approximately 22 ohms. this is give or take because the sender reading is variable and not linear.

OR

The resistor on the gauge is low enough not to allow the gauge needle to advance to full.

This would not seem to be the case when the gauge needle goes to the three o'clock position when the sending unit wire is disconnected. Have we established that in Mr. JJZEPPLIN's case?

There is also the possibility that there is a defect on the needle deflection coils inside the gauge itself. The thing to understand is that the amount of resistance on these coils allows them to pull the needle left or right depending on which coil has the least resistance. These coils are protected by the resistor on the gauge as well as affected by it.

Here is a favorite diagram of mine on the fuel indication circuit on many vehicles.

I don't think it shows the complete wiring on the gauge internals but is trying to show the relationship of the sending unit resistance to the gauge.

The variance on the gauge resistors is probably due to the gauge needle, coil windings on different models and the number and size of their windings.

I might suggest an experiment to test my theory. The resistance across the fuel gauge terminals is 44.4 ohms per the picture in the first set. Let's reduce the ohms of this resistor by an amount that only allows 1/4 tank reading on the gauge when it includes the full 90 ohm tank resistance. Keep in mind that this resistor protects the gauge coils, so a small nine volt battery might work for the power input without damaging the gauge.

I see that you have used a battery charger with probably a 2 amp setting so that should fit the bill.

So here's what we have.

Battery positive to the gauge positive terminal.

sender resistance of 90 ohms to sender side with the end of the resistor grounded to the ground terminal.

Battery negative connected to the same ground terminal as the sender resistor. This should give a reading of full on the gauge. I'm out of state at the present so I can't do this myself to prove my theory.

Next we will substitute a lessor value resistor for the one on the back of the gauge and determine if the reading drops below full. We know it will if we change the sender resistance because that's how the system works. Less resistance on the sender equals a lower gauge reading.

To sum all this up I'm asking the question "What happens if the gauge resistor goes bad by shorting across it's coils and dropping it's resistance." Does it prevent the gauge from going above 1/4 tank or is it something else?

What happens if we replace the gauge resistor with one of a higher value.

I'm not playing here, I really don't know.