There were quite a few loose ends to tie up with both the drivetrain swap along with the overall truck itself. Ill cover the tip of the iceberg on them in these last few catch up posts.

October 2018 - Since changing out the transfer case output housing from the Dodge unit to the Chevy unit, I was able to hook up my speedo cable. I have no idea where I will be with speedometer accuracy, but I figured I would find a speedo reading, an RPM reading, and a GPS speed and find the correct ratio box once she is driving. I was also going to change out my speedometer cable because it was just barely too short until, after doing some research on speedo ratio boxes and adapters, that I remembered that my dad had 90 degree box for his 69 Vette that he hadnt gotten around to installing and it just so happened that it was exactly what I needed.

October 2018 - As I mentioned in an earlier post, I had been dreading the wiring for quite a while. It was the biggest obstacle that was preventing me from making some ground on this build for the longest time. I installed the AAW fuse panel and the under dash kit for it back in 2016 or 17 and hadnt touched it since. I think that getting the custom fuse panel to tie the basic truck wiring to the engine and drivetrain wiring was a huge help to this though as it gave me some clarity on what needed to be completed, where wires needed to be routed, and what their function was. The only wiring left to do is the rear light harness and it should take about as long as the front light harness which wasnt but a couple of hours.

I do also have the grid heaters to wire up. I have everything for them, but at this point, they are not crucial to driving the truck so they arent the highest on the list at the moment.

The first time these headlights have been lit up on her.....

I knew the time would come to have to try to get the body aligned on this frame that this body was not originally on. In preparation for that, rebuilt the door hinges so I wouldnt have to do it once the fenders were mounted.

Thats about enough of those!

Once I got the doors back on, I test fit the fenders and noticed I had quite a bit of a tapered gap between the door and the fender. After some asking around, I guess it is standard to shim the body mounts to get the gaps to work out right. Not being a body guy and never gapping body lines before, I think that these turned out acceptable to me. I ended up shimming the front cab mount up about 1/4"-3/8" to get the gap uniform.

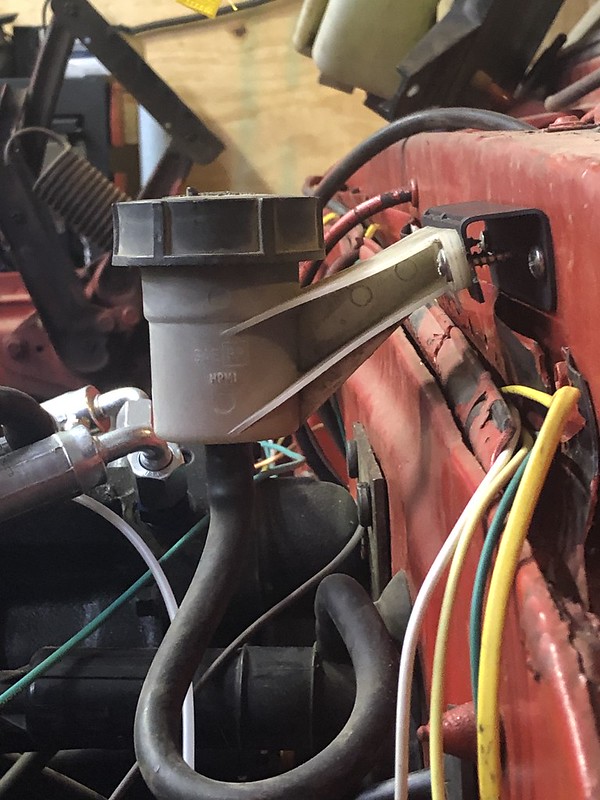

Anther item that was lingering for far too long was the clutch hydraulic reservoir mounting. I was just going to try to fab something simple in the barn to mount it but ended up throwing something together on the waterjet. Still simple, but much cleaner than I would have been able to fab up.