|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Senior Member

Join Date: Apr 2017

Location: Suwanee GA

Posts: 239

|

Re: Parking brake question

Of the two I like the e-stopp. since it uses the normal cable e brakes.

My only thought would be they should improve it to have push on and off variability. Seems its either all the way on or all the way off. Would be nice to give you control just like you would with a hand driven brake. Maybe version 2 and only for x dollars more. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

Funny I was thinking the same thing. Instead of just a button for on and off, a potentiometer to vary the intensity of the "pull".

After I made that last post, I went and cancelled the order for the Mico unit after I thought about fussing with brakes lines......yet again. I do like the idea of using the existing cables to the rear calipers. Now to find an installation spot that works. HAs anyone here done that already?

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Mar 2022

Location: Surrey BC

Posts: 755

|

Re: Parking brake question

the e-stopp appears to be just a motor driven screw thread, and from reports not a very fast acting one. DC motors are pretty constant torque so all you will do with a potentiometer is change the speed, not torque unless you make a motor driver circuit.

buying a PWM controller premade would be easier. But not make the motor any faster. And you'd need some strain feedback loop to make it work well for modulated braking I think. Hard to make something remotely actuated and as fast acting and well modulated as a pull up handbrake with thumb release. Maybe a pneumatic system. The estopp if it works as advertised should be a fine parking brake. And a slow acting ebrake that will slowly increase braking pressure. perhaps not ideal, but way better than nothing. Let us know how it works if you switch to this! You have already switched to dual circuit hydraulic brakes, keeping those in good shape is the main thing. Before you put it on the road I'd test each side of the dual circuits to make sure that a failure still leaves you with pedal pressure on the nonfailed side: that the pedal does not hit the floor before the remaining circuit in the master builds pressure. If this is true, unless you have a catastrophic failure of the pedal/master unit you will be two failure points away from having to rely on the estopp as an emergency brake. |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

I'll probably skip trying to invent a new way to graduate the pressure of the E-Stopp system and just go with what they provide. I just spent and hour ripping out the old foot pedal mechanism and measuring to cut a patch panel to fill in the holes on the floor and firewall. By the time it gets here, I'll be ready to try to find a suitable location and mounting system.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Mar 2022

Location: Surrey BC

Posts: 755

|

Re: Parking brake question

It would be pretty cool to mount a push/pull switch in the factory brake release bracket under the dash and use the original 'B' knob as the switch for the e-stopp

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

Now that has me thinking!!!

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,396

|

Re: Parking brake question

I forgot that fauXGT had shown his cable setup before. The cable can be run back to operate what ever rear park brake setup you have with just a bit of thinking and effort.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

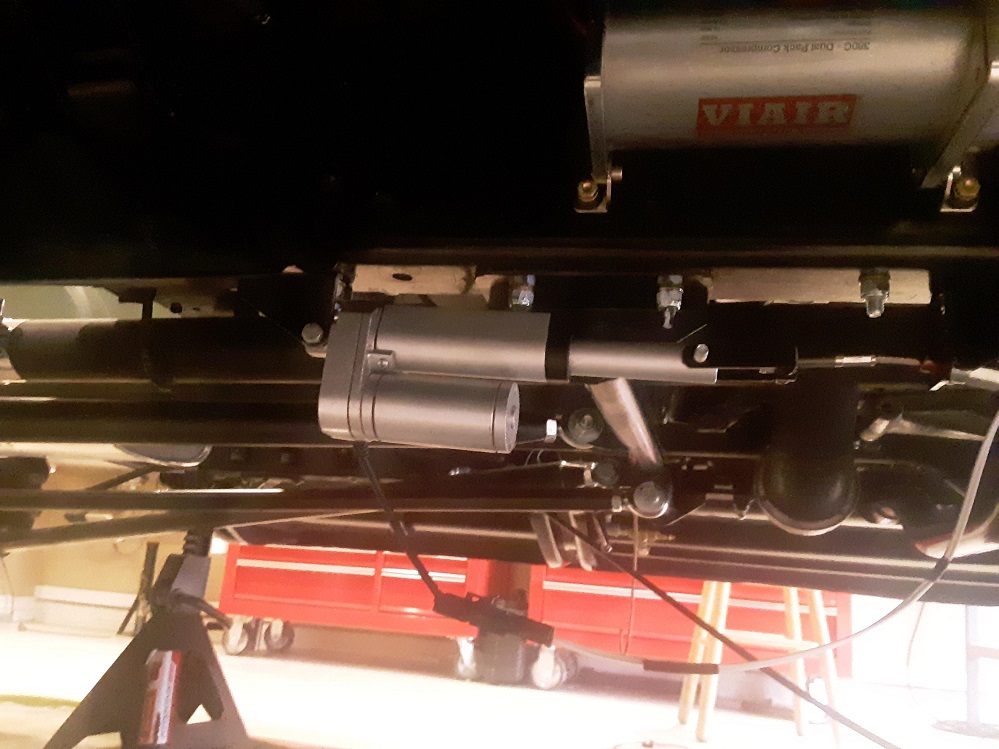

So here is the linear actuator, now to figure out how and where to actually mount it.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Apr 2017

Location: Suwanee GA

Posts: 239

|

Re: Parking brake question

take a picture of you underside above transmission. the least amount of cable turns and routes would be easy to work on test and adjust in my opinion. Just thinking the place i would look would be centered offset to one side of drive shaft or trans hump on passenger side. with a couple of crossbars between cross members. off center to allow for full suspension travel and trans. but hey there are plenty of options. if its near any exhaust runs you will want some heat shields to reflect radiant heat.

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Mar 2022

Location: Surrey BC

Posts: 755

|

Re: Parking brake question

I know you are rear disk, do the brake cables still go to the original brake cross bar? If so I'd find a spot on the frame in front of the cross bar where you could bolt the estopp (or bolt a bracket to mount the estopp on) and then weld a new tab onto the cross bar for the unit to pull on.

stealing mr48chev's picture from post 25, something like this. But it could be either side or even on outside of frame rail pulling on a tab added the part that clamps on the outside of cross bar Last edited by leegreen; 05-27-2024 at 01:15 PM. |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

I have bought two c-channel steel bars that I will powder coat and bolt to the bottom of the frame to support the E-Stopp linear actuator. I just did a test fit before I start marking and drilling.

This and a few other things have become my boredom projects while I wait oin my engine rebuild. Next I am thinking of replacing the standard key operated ignition switch with a key switch that is only used to turn off the electrical power to the accessories and to provide power to a starter button. I haven't figured out the correct wiring configuration yet, but after wiring the whole truck, it can't be that hard.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Mar 2022

Location: Surrey BC

Posts: 755

|

Re: Parking brake question

Do you have driveshaft clearance there?

Next you can fit those kick panels! |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

Good catch. I realized last night in bed that without a driveshaft everything fits. So this morning I ran a string from the diff to where roughly the trans would be and itís a no go. On to plan C

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Apr 2017

Location: Suwanee GA

Posts: 239

|

Re: Parking brake question

just put the bars front to back not left to right.

This will solve the cross over the drive shaft they will be only 4 inches apart and can be off set of the drive shaft. you can go between the bed bars or the frame bars or both a small angle will not hurt. |

|

|

|

|

|

#15 | |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

Quote:

I'm thinking of mounting the bars on top of the rear frame member above the parking brake mechanism and them mounting the bars with a metal plate directly to the cab floor board where it bulges downward. See photos with arrows pointing to the two mounting points and to the brake mechanism where the E-Stopp would attach via a clevis.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 7,914

|

Re: Parking brake question

i would try to keep all the permanent parts I could attached to the frame instead of the body. it is going to make some noise when actuated so cab mounting will exagerate the sound likely.

if I were mounting it i would take some flat bar and bent a couple of U shaped brackets with a squared off U and bolt them to the top and bottom rails of the frame and bolt the unit to them so that it would be spaced off the web of the frame and allow access behind it for brake lines, fuel lines, wiring etc and also allow free space for the cable to exit with room to connect to the original brake actuating crossbar. a new lever could be welded onto the crossbar to line up with the Estop unit. a connector link could be made if the estopp needs to be further forward so as not to be in the way of exhaust, trans crossmember etc. sorta like LG's idea but a little different mounting method so as to space the unit off the frame a little. a short length of square tube could also be used if one side of the tube were cut away to create a long U style bracket. if there were nothing on the web of the frame yet the square tube could simply be bolted to the web of the frame to act as a spacer to space the estopp unit away, and the things that normally get run along the frame web could still be run along as normal except they would run through the square tube. attaching to the frame instead of the cab keeps all the hard parts attached to the same main part, be that the frame OR the cab. then a simple, weather sealed, wiring connector would unplug the estopp if the cab were required to be removed or the estopp unit required service or replacement later |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

All you guys are always so helpful. I've looked at each suggestion and by now, I'm on Plan G, but think I found a plan that will work. I agree that mounting to the cab floor was less than optimum and really didn't want bolt heads under the carpet.

So using a combination of what was suggested what I've come upon are shelf brackets (L-Brackets) that are 10 inch by 6 inch. I need to cut off an inch or so from the six inch side, then they will fit in the frame c-channel. I will drill a few holes to mount them to the side and bottom of the channel (maybe the top of the channel if they fit properly). Then I will bolt a piece of 16 gauge steel to these brackets. The ten inch side will extend out from the frame about eight inches. Then I can mount the E-Stopp to the 16 gauge at an angle to the existing tab on the rear brake mechanism. I've also decided to wire in a waterproof two wire connector to the E-Stopp so I can remove the entire assembly if needed. Thanks to all, photos to follow when the assembly is done.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Mar 2022

Location: Surrey BC

Posts: 755

|

Re: Parking brake question

Sounds like a solid plan.

Still room for exhaust on that side? |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

I think so, thats part of what I have to test and why I might angle the brackets to the top of the frame and let the E-Stopp hang from the brackets rather than sit on them.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

i turns out I do have an unexpected dilemma. The end of the threaded rod on the E-Stopp is metric threaded M6 - 1.0. i have searched high and low for a forked clevis that has metric thread of that size and come up empty. I've even searched for a small threaded Heim joint to bolt onto the tab on the brake mechanism. All searches have some up negative, any thoughts or alternatives wlll be appreciated.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 7,914

|

Re: Parking brake question

Just fab a clevis or retread one that works. A threaded adapter with metric on one end and standard o the other end is a possibility

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 767

|

Re: Parking brake question

I don't have one of those ebrake thingys - mine is just a 300 lb linear actuator connected with a DPDT switch in the cab. The clevis is just two pieces of flat stock welded to a nut. It isn't real pretty, but it is hidden under the truck? I mostly did this because I didn't want to wait for an order or pay shipping at McMaster -Car. But if you do, they list a clevis end in M6x1 for about $12 plus shipping https://www.mcmaster.com/products/clevises/rod-ends-1~/ |

|

|

|

|

|

#23 | |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

Quote:

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Mar 2022

Location: Lucas, TX

Posts: 496

|

Re: Parking brake question

i have roughed out a mounting method using the 1/4 inch shelf brackets. They sit inside the c-channel of the frame and are bolted. I will probably cut some 16 gauge steel to lay on top of the brackets, then bolt the E-Stopp to the steel plate. So far so good, and I'm fairly certain that this is out of the way from the exhaust and drive shaft. More work to continue.

__________________

1953 Chevy 3100 - 5 window 1/2 ton pickup My 1953 Chevy Work-In-Process Photo Gallery "I don't have a carbon footprint, I drive everywhere." |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Nov 2010

Location: calgary alberta

Posts: 7,914

|

Re: Parking brake question

just heads up on the mounting system that you may have overlooked. the mounting of the haevy part is just to keep that part from flopping around etc. the working part of the cable connection is an important part and has nuts on the outer threaded part for a reason. the first part to fab and mount, before you bolt down the heavy part, is the mount for the cable connection outer part. this should be inline with the cable or rod that comes from the rear. if using the original crossbar, the lever where the rod used to connect to the front mechanism should be moved over to be inline with the new mechanism and made to the correct length to allow a proper amount of travel for the rear cables and also be within the travellimits of the estopp. after getting this figured out and the cable end mounted firmly then the estopp heavy part can be bolted down. this way it is the cable mount that will be taking the major strain, as designed I think, and the mounts for the heavy part will be for holding that part firmly on the frame.

make sense? there is a mounting video on the speedway site that maybe explains it better. first the cable is mounted and adjusted and then the heavy part is mounted and adjusted to that. remember the cable comes in the fully extended position. I guess what I am saying is don't rely on the body of the estopp for taking the strain of the pull when the unit is called into action, it isn't designed that way and may fail. the cable outer part should be the part taking the strain and so should be attached to the heavy duty mounting bracket. behind that is the heavy part that required a mount heavy duty enough to hold the weight of that part but it doesn't actually take the strain of the brake application, that is the outer cable mount job. |

|

|

|

|

| Bookmarks |

|

|