|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

TH350 Rebuild Troubleshooting

I'm rebuilding my th350. it is my first trans rebuild. based on the pics below, can anyone suggest causes for what has happened, and places to focus when deciding if components need to be replaced? i honestly haven't driven this truck enough to describe how the trans was functioning (maybe 100 miles since I bought it almost 3 years ago,) but it seemed to me to be working fine for a 40 year old drivetrain. I had the trans out to inspect the flexplate (which was slightly warped) and noticed the scoring in the converter neck, which then pointed to the trashed pump bushing. Thats when I decided that it would need an overhaul, and on disassembly I discovered the shattered intermediate pressure plate. I presume that these are results and not causes (at least the pressure plate), so is there any place I should be looking - pump, valve body, governor, modulator, seals? I plan a rebuild with seals, bushings, thrusts, and bearings, in addition to the clutches. I suppose I'll need a new converter - can anyone suggest vendors for stock converters and rebuild kits? Thanks for any insight/recommendations - mark

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Apr 2000

Location: Delta,Pa

Posts: 14,950

|

Re: TH350 Rebuild Troubleshooting

The warped flex plate could have caused all of your issues. Any wobble in the converter and everything behind it can get destroyed. Converter should be replaced with any rebuild. I would also suspect the pump housing and gears themselves will be tore up. You need to split the pump. At this point it might be cheaper to find another transmission to rebuild that doesn't need so many hard parts. Generally you can find a core for under 100 bucks the problem is finding one.

__________________

Owner of North Point Car Care in Dundalk Md. We specialize in custom exhaust on both modern and classic vehicles. We are a full service auto shop from classics to modern vehicles. Feel free to contact me with questions. I will give a 10% discount to any board member. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

Thanks for the reply, Cableguy. This whole exercise started when I tried to install a new starter and it wouldn't line up with the flexplate. By the time I got to dropping the trans, I noticed that of the 6 bolts fastening it to the block, one had been shorn off, and two were missing - basically held in by three bolts. I don't know if that is what caused the problem, or a result. Not sure how a flexplate gets warped. Anyway, I'll disassemble each of the various assemblies in the trans, starting with the pump to assess any more damage. You think that if the pump gears are wasted it's not worth rebuilding?

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: TH350 Rebuild Troubleshooting

The pump gears need to be replaced in most TH350's anyway, Cableguy is referring to the Pump Halves being screwed up (Cover & Body).

Separate the pump, Remove the Gears from the Pump Body, Inspect the "Pockets" they run in. 1st pic shows the pump body with the gears still installed. Inspect the Pump Cover, This will tell you MORE than the Pump Body will....If it has groove worn in the Face....The entire pump is trash, The arrows point to the witness marks left by the large Pump Gear, Look for damage inside this circle....This is a TH400 Pump Cover, & in Perfect shape...TH350 is similar.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: TH350 Rebuild Troubleshooting

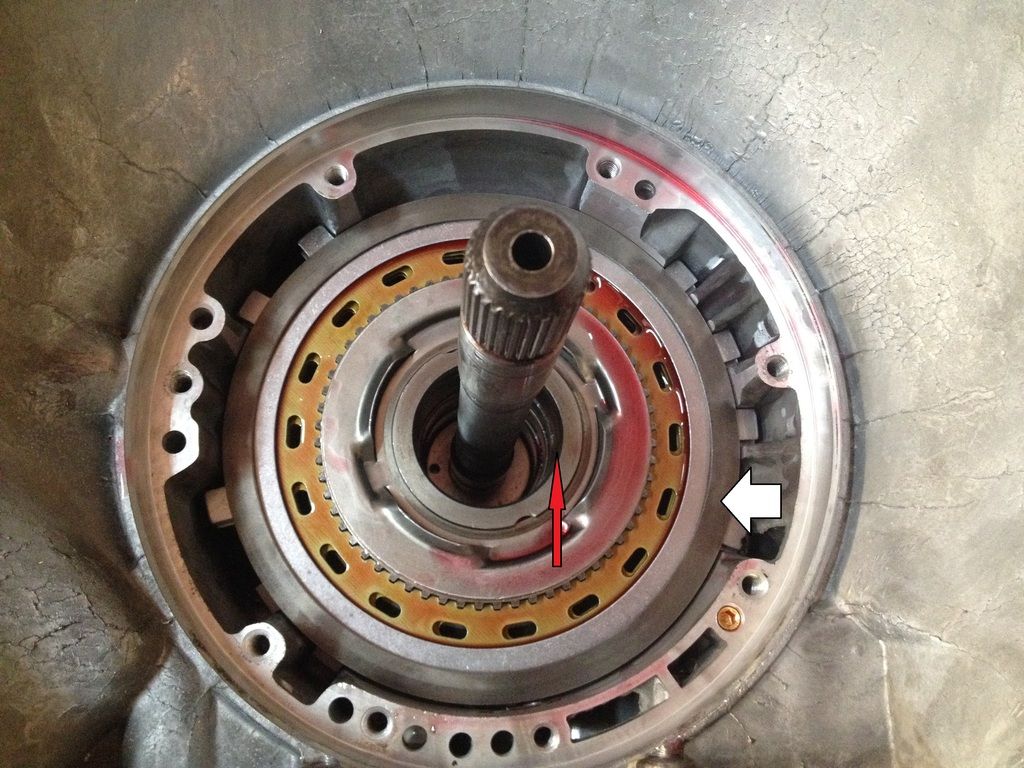

Check for Stator Support wear, This is where the Direct Drum rides, Red arrow is where the Direct Drum bushing rides, The White arrow is the Lateral Thrust Washer for the front of the Direct Drum.

Check the Direct Drum Bore for sealing ring wear (Red arrow). Was the Intermediate clutch Wave Plate present? (White arrow).

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

First of all, thanks for the advice Clinebarger! I finally found time to get back into the garage to inspect the areas that you indicated. I opened up the pump and inspected the direct clutch assy as well (but have not disassembled it yet (need to make a spring compressor tool.) I did find some burnishing with a little scoring, but it really didn't seem that bad.

The pump well had a little scoring that i could feel with the pick, but barely  The pump cover had marks, but no scoring - i could not feel anything with the pick  The pump gears looked fine, the only thing that I could see was that the bottom inboard edge of the teeth might have been bevelled a tiny bit? Not sure if its supposed to be that way or not?  The forward part of the stator support had a bit of discoloration, but no scoring again couldnt feel anything  The rear part of the stator support had the worst scoring, i could definitely feel it with the pick, but the lighting on the picture makes it look worse than it is.  The bore inside the direct drum showed wear from the stator support rings but not scoring (more like the wavyness on a disc brake,) the bushing inside the direct drum looked/felt fine and smooth  So, does the wear visible in these pics help explain any of the damage in the previous posts (heavy scoring on the converter neck and a shattered intermediate clutch pack pressure plate?) And more importantly, does it look like I need new hard parts? (I hope not!!!) Thanks for any suggestions/advice - mark

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

Also, i forgot to mention that the intermediate clutch wavy spring was present. thanks - mark

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Apr 2000

Location: Delta,Pa

Posts: 14,950

|

Re: TH350 Rebuild Troubleshooting

All of those surfaces should be a smooth machined surface. If they aren't you will have issues. In my opinion the flexplate is the cause of all the damage. It caused the converter to wobble which tore everything else up. All of those damaged surfaces can cause sealing issues and will bleed off pressure. The pump needs to be perfectly smooth. If it isn't it wont build pressure properly. I personally would find another transmission to use as a core to rebuild. The price of the parts you need will cost more than just getting a core unit for 75 or 100 bucks.

__________________

Owner of North Point Car Care in Dundalk Md. We specialize in custom exhaust on both modern and classic vehicles. We are a full service auto shop from classics to modern vehicles. Feel free to contact me with questions. I will give a 10% discount to any board member. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: TH350 Rebuild Troubleshooting

There is definite wear, That pump cover looks pretty bad....But I know pictures can be deceiving.

The sealing ring bore in the Direct Drum needs to be straight with no "waves", What causes that wear is too much end-play, Allowing the drum to walk back & forth on the Stator. Is the 2nd Accumulator Spring in place? Did the unit shift hard? Still don't see why the intermediate backing plate broke, It could have been just "It's Time" to break.... To be 100% honest....You could throw Bushings, Pump Gears, Intermediate Backing Plate, & Frictions in this unit & it will work for awhile, That's how TH350's are....I have dug a pound of metal/friction material out of TH350 pans before thinking there is no way this thing will pull much less shift.....Lets just say, I don't bet against a TH350! If your trying to "Get by" cheap as possible.....Go ahead. If you want this thing to go 100,000+ miles.....Find a good core & build this thing right! BOP TH350's are usually cheaper & Usually in better shape Hard Part wise. Then transfer everything into your Chevy Case. Speaking of the Case, Check for Lug wear where the Center support rides, Also check for Governor Bore wear. |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Aug 2013

Location: sumterville, florida

Posts: 914

|

Re: TH350 Rebuild Troubleshooting

curious why you would say bop trans are usually in better shape unless it's less usage. in my past life i worked at chevy, olds, pontiac dealers and, while not keeping count, it seemed like no one line had more issues. on another note in the 70's there was a th350 campaign that affected olds only which i thought was strange.

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: TH350 Rebuild Troubleshooting

More of a Truck vs Car thing, Truck cores are always in worse shape....Especially in 4x4 trucks. BOP cores are in less demand, Making them cheaper. And no risk of buying a truck core.

TH400's are the same way...The best hard parts come from BOPC & Jaguar cores. |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Aug 2013

Location: sumterville, florida

Posts: 914

|

Re: TH350 Rebuild Troubleshooting

i was actually thinking car vs car but the truck thing makes sense

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

Thanks for the replies, guys. So at a minimum, a new pump and direct drum. With used parts, should the pump and cover be matched or can I use halves from different cores as long as the gears mic and the cover has no wear? How far in the hole should gears be?

2nd Acc. spring is present. Cant comment on shifts - literally do not have enough miles on it to know. It's ironic that you suggest getting a BOP core. one of the reasons i've been willing to undertake this chevy th350 rebuild is because the th350 in my A body cutlass developed a fault this past summer (it wont go into forward gears) so i thought id learn about the rebuild on the chevy (which at the time i thought would only need a refresh), then troubleshoot and fix the bop. now, ive decided that with the chevy needing parts and overhaul, what ill do is look to see if the bop can supply the necessary parts to get the chevy rebuilt and then build a 200r4 to put in the cutlass. its a long weekend, ill pull the bop trans and see what i can scavenge. when i bought the cutlass in '95 from the original owner the odo said 88k. i know ive put 100k - so there are at least 188K on this trans though.

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Feb 2010

Location: Falls City, Nebraska "100 Miles From Nowhere"

Posts: 2,219

|

Re: TH350 Rebuild Troubleshooting

Right there with you buddy...I hit a snag or three today with my primary rebuild. Three of the pump bolts stripped before reaching the 15 ft lbs of torque and when I checked the governor lands, they specked out at .799" and the bore is rough looking and feels rough, not good! This tranny became a back-up tranny today. I measured the hole depth and the bolt length on the stripped pump bolts and there was 3/8" of unused hole depth. I stuck 3 bolts that were a 1/4" longer than the factory bolts and pulled them up to 12 lbs. Cleaned up the governor bore and reassembled it. I'm confident it will run, but dont know for how long...? I have a late model 350THM out there that I think is a 350C model, I'll take a look at it Monday or Tuesday and see if it's worth saving...

__________________

Michael of the clan Hill, "Two Seventy Two's" 71 1-ton Dually 350 4-Speed 71 C/50 Grain Truck, 350 Split-Axle 4-Speed 02 3/4 ton Express 14 Indian Chief Vintage 1952 Ford 8N, "Only Ford Allowed On The Property"  "Be American, Buy American"

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

inspecting the chevy case, it shows heavy wear (i think?)

I started removing the bop trans, but man was it cold today - the fingers get cold wrenching outside. i should be able to drop it tomorrow. so im unsure how to proceed. would a case saver make this case useable? if so, for $110 i could continue with the rebuild hoping that the bop will provide the hard parts i need, or trust my luck and buy a used 4wd core for probably about the same price. i'm trying to keep costs to a minimum - this truck is going to be a work truck and isnt worth spending money if i can DIY it. thoughts?

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

I'm finally getting around to the reassembly of my th350. i'm doing the valve body (VB) and have run into a bit of confusion as to which spring to use in the Manual Low Control Valve (MLCV). Basically, I have two transmissions, from which I am taking the most serviceable parts to build my replacement trans. Therefore, I have two MLCVs to choose from - the problem is that it appears that neither is an original factory part, so which should I use for my application?

Referencing the photo below, the one on the left came out of the "original" trans from which I am using only the VB. This trans had some kind of Shift Kit installed, because it had the orange pressure regulator spring and aftermarket separator plate (without the dual feed option). So i don't know if the spring in the MLCV is original or aftermarket? The valve on the right is from the rebuilt trans which will be going back into the truck. I bought it off Craigslist and the seller told me he had it in his K10 but that the internals (except for the output shaft) began life in an Olds. I don't know if this included the VB or not. It too had a shift kit installed, this one included the dual feed separator plate. It looks to me like the spring on the right is the TransGo "blue" Gear Command spring? For my VB, I will be using the original trans VB with the rebuilt trans valve assemblies, and a new SK-350 shift kit from TransGo (I did the case modification for dual feed.) The shift kit tells me to use the stock valve assembly for manual low. My question is, since I can't identify either of the springs as being "stock" which one should I use? My application is a work truck that will be used for hauling mostly. Thanks for any help.

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: TH350 Rebuild Troubleshooting

The MLCV is too prevent a Manual 1st Downshift at speeds 35-45 MPH & Higher (Governor calibration affects the actual minimum speed), Keeps the connecting rods inside the engine in the event of a Loose Nut behind the wheel......

Try both springs, If they both block the valve from moving, They both serve the same purpose of allowing manual downshifts too 1st at any speed. If you do not accidentally or intentionally downshift at high speeds.....I wouldn't worry about this, If it is a concern for you.....Find a stock spring. |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Aug 2013

Location: Annapolis, MD

Posts: 82

|

Re: TH350 Rebuild Troubleshooting

Thanks (again) for your reply, Clinebarger. I did what you said and checked both springs in the VB. The spring on the right with the tighter coils does not allow the valve to move - it bottoms out very quickly (like it's basically a spacer). I presume this is to block off the governor signal and allow manual shift to low at any speed. The spring on the left allows the valve to move through its full-range, which I guess allows for input from the governor to stop 1-2 shifts once the pressure (speed) is high enough. I used the spring on the left - no need to chirp the tires in third with this hunk of rust (maybe I'll put it in the Cutlass???) I appreciate you willingness to share your knowledge and help me learn something!

__________________

'80 K30 c&c std cab dually (CKM33AB 10000 GVW) D60(4.10)/350 crate/400/205/14 |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|