|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#76 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

The rest of the hood was straightened with the same process at the dent on the side.

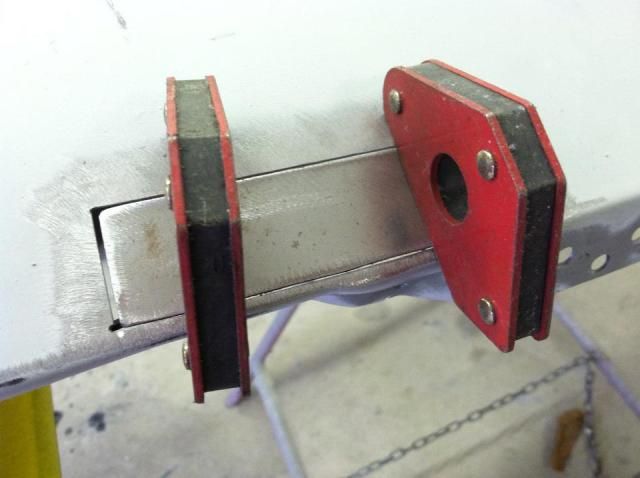

After the hood was straightened, I wanted to check the fit of the hood against the cab. I leveled the cab and used half of the rotisserie to hold the front of the hood.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#77 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

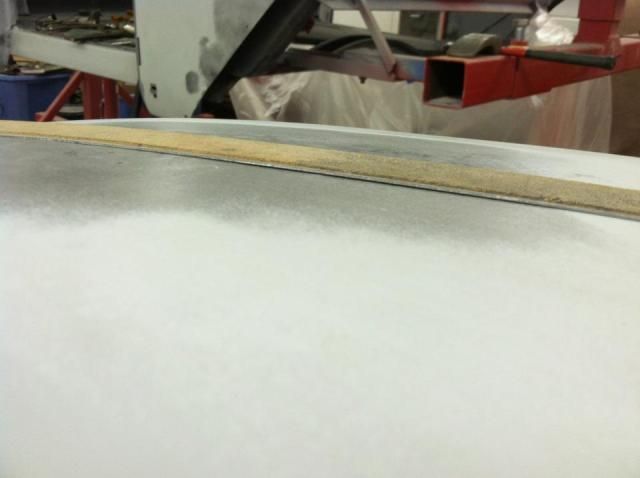

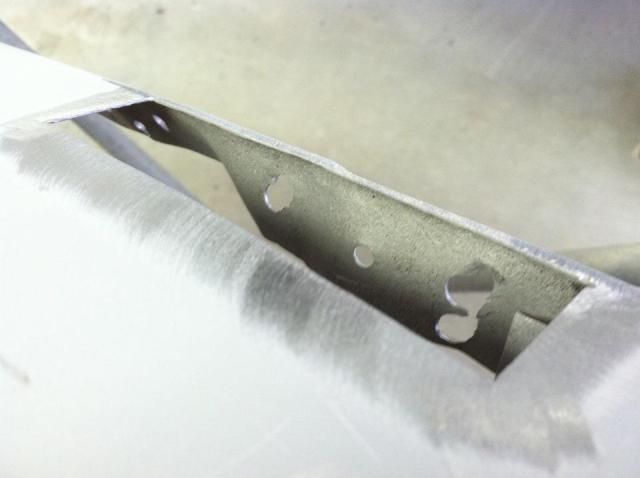

The left side of the hood line up great with the cowl, but the right side was bent out 1 7/16".

1 7/16" gap on the driver side.  I cut three slices in the inner brace while it was on the truck, pulled the hood into shape, then tack welded the brace back together. This pulled the hood edge back into place against the cowl. The cuts were fully welded up and the weld beads smoothed down.  After cutting and reshaping the brace, much better fit.   Left side still looks good after reshaping the right side.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#78 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

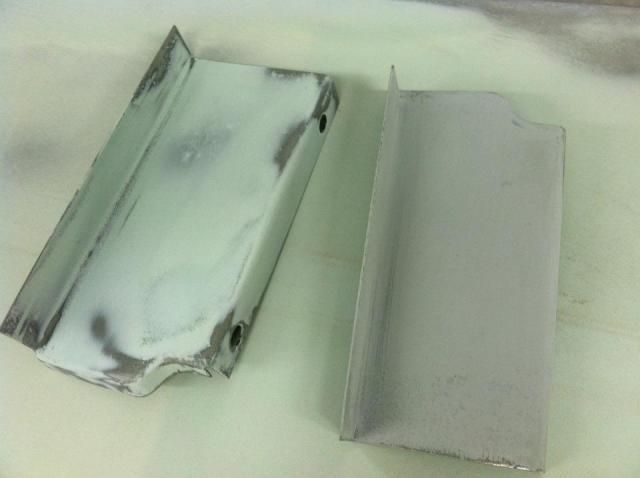

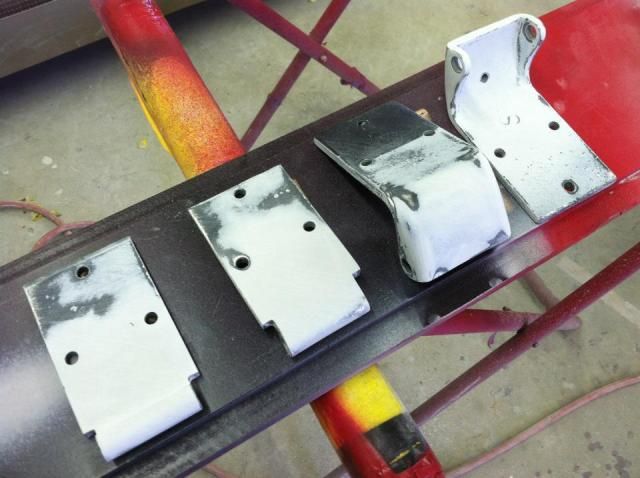

The hood latches had surface rust so I bead blasted and painted them. Glass beads are great for latches since they are easy to get out of the latch mechanism- no gritty residue left over.

Stamping L&R to keep them from getting mixed up after blasting. Marking them with a marker only works if the part isn't getting stripped and repainted.  Bead blasted.   And painted.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#79 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

The fenders were a nightmare!! The tops were fairly straight but everywhere else had major damage!

This is the passenger front fender, with a huge dent on the wheel opening lip. The lip was severely pushed back into the fender, creating a large bulge around the dent.  Crumpled front lower area.  Rear bottom area had been crease and halfway repaired.  Large area of damage on the rear section.  More dents on the front, and the wheel opening lip was cracked.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#80 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

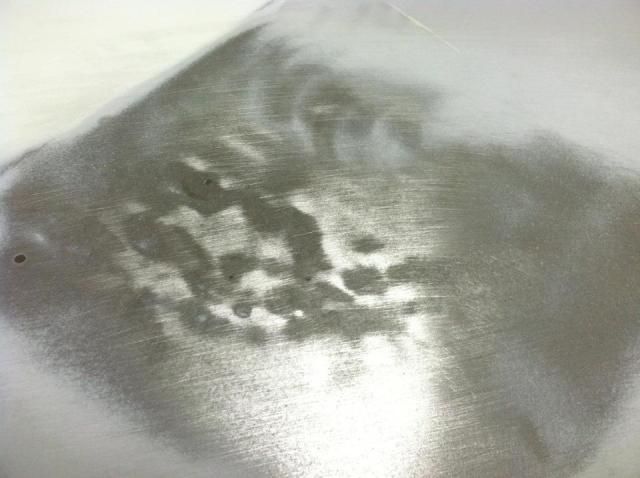

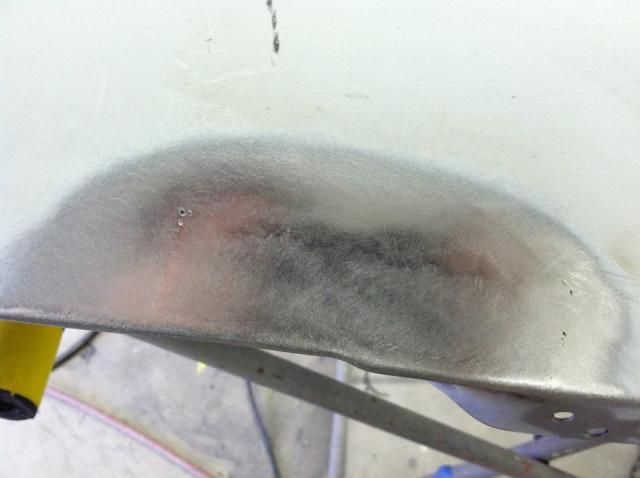

Fixing the large dent on the wheel opening lip.

Before.  Beginning to work the metal back into shape. This shows just how much the metal had been pushed around.  Shrinking, and hammer/dolly work to bring the raised area down.    Checking the opening edge shape with a long, flexible ruler.  After more shrinking and H/D work.  Finished up, the ruler edge would lay down flat all along the opening.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#81 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

The bottom edge was pushed in, and there was a fender brace bracket that was bent out of shape.

Bottom edge straightened, and the bracket area back in shape.   Heat shrinking with a torch to get the creased area back flat.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#82 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Forgot to mention that I did all of the repair work on the fenders with the front clip assembled to hold everything in shape. Fixing the fenders on a bench or stand would let them flex abnormally, and the repaired areas would have the wrong shapes/contours when bolted up.

Front bottom edge was crumpled.   Gap between the fender and grill straightened out.  Metalshaping finished.  Inside bottom edge was chewed up pretty good. I opened it up to straighten the kinks out, then re-rolled it.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#83 |

|

Registered User

Join Date: Apr 2012

Location: Beaver, Pa.

Posts: 197

|

Re: '55 International Metal/Body/Paint Work

Just found and read this thread from the beginning, amazing work. I have to echo what the others have said, it's great to see an oddball truck like this get saved! It's the unusual stuff at the shows that catches my eye.

|

|

|

|

|

|

#84 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Quote:

The driver side fender wasn't anywhere near as bad as the passenger side. It had a spot of rust from moisture trapped between an inner brace, and around the front of the wheel opening lip had some damage. Heat shinking the damaged area after roughing out the shape.  After heatshrinking and sanding with a DA to smooth the surface, I blocked the damaged area to find the high/low spots.  After a few rounds of hammer/dolly work and block sanding to pinpoint the high/low spots and work them flat.  The front edge was bent where it bolted to the grill panel, so I straightened that out.   More damage around the wheel opening, it got the same heatshrink/block/hammer and dolly treatment.  The upper edge of the fender lip was uneven, so I made relief cuts to straighten the edge.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#85 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

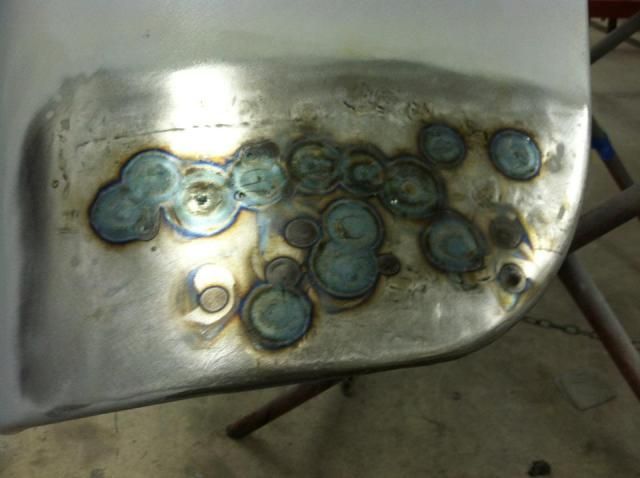

Fixing the rust on the top of the fender required removing the inner brace that caused the rust to begin with. You can see where someone tried to fix the rust hole in the past by packing it with filler.

Inner brace removed. You can see just how much rust was hiding in there, and how much was dislodged just by removing it.    Inner brace sandblasted.  Making a new side for the inner brace.    Rusted area of the sheetmetal cut out and new metal welded in. The area that was underneath the brace was sandblasted as well.     The backside of the brace and the fender were coated with etching primer before welding the brace back in. This will keep rust from forming under the brace again.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#86 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

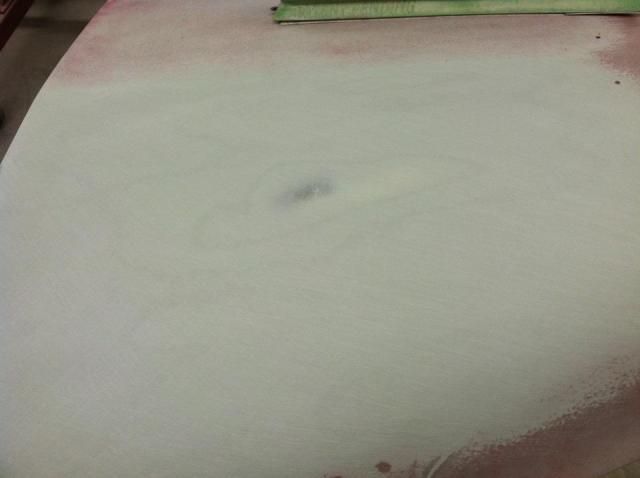

With the metalwork out of the way, I skim coated the fenders and hood and blocked them straight. Then they got three coats of Slick Sand, and more blocking.

Sprayed with Slick Sand.   And blocked flat.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#87 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Some details of blocking the Slick Sand. I block the primer down until I hit bare metal. This way the primer is as thin as possible and doesn't have to thick of a build to become unstable if the panel has any flexing- preventing cracks. You can see the different coats of primer being blocked off around the high spots.

On body lines and details, I sand the flat section first, cutting into the body line with the edge of the block until I hit bare metal. This cuts the body line straight and keeps the primer build up in the line to a minimum.  With the upper edge cut and leveled, it gets taped up so blocking the bottom half doesn't damage the upper part that's already straight.  Both sides blocked, keeping the body lines straight and well defined. This will really make the paint stand out in these areas after cutting and buffing.  Same treatment on the front edge of the raised stamping.  Minor low spots are touched up with filler and blocked down. If the metalwork and skimcoat/blocking was done correctly, there are very few areas to rework after priming and blocking with Slick Sand.  The flat areas of the fenders were blocked first, then a flexible sanding pad was used to sand the wheel opening lip, making sure to keep an even radius around the lip.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#88 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Here's a shot of my sanding blocks. The white tube is PVC for blocking concave surfaces. The long/skinny Durablocks are great to cut down shorter for smaller areas.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#89 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

There were a couple of filler panels that mount to the fender bottoms that needed straightening.

The cowl vent rain tray had what looked like hammer marks that needed to be shrunk and straightened. It has already been blasted but had rattle can primer on it that needed to be stripped. It was sandblasted before skimcoating and repriming.     The glovebox door was sandblasted and prepped for primer.  Primed with Slick Sand and blocked flat, ready for tinted K93.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#90 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

The windshield trim panels needed stripping repair. They were treated with PPG DX series Metal Cleaner and Metal Conditioner before being primed with DP90.

The dash panel needed stripping so I covered it with rags soaked in lacquer thinner, then covered that with tinfoil until the thinner softened the paint enough to scrape it off.     After scraping off the majority of the old paint, I sandblasted the dash panel. I didn't want to just blast the paint off and take a chance of warping the metal since it was thin and didn't have any shape to strengthen it.  Treated with PPG Metal Cleaner/Conditioner.  Primed with DP90  And three coats of tinted K36.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#91 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

The hinges were primed with DP90, then scuffed and shot with Slick Sand the next day.

After block sanding, ready for K36.  The floor/firewall panel was blasted, primed with DP90, and seam sealed before being sprayed with three coats of homemade Lizard Skin type sound deadener/heat insulation.     Dash panel sprayed with Slick Sand and block sanded.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#92 |

|

Registered User

Join Date: Mar 2005

Location: apple valley, ca

Posts: 2,670

|

Re: '55 International Metal/Body/Paint Work

Amazing work, John. Most people don't have a clue at the effort and time that it takes to get a body to that level. That International looks especially daunting because you don't have the luxury of a separate, floating grill or chrome pieces that you can hide mismatches underneath. That whole front group is out in the open, with miles of panel gaps to address.

A Master at work...............love this thread!

__________________

Check out my latest endeavor: https://roundsixpod.com My build threads: '55 Chevy: http://67-72chevytrucks.com/vboard/s...d.php?t=247512 '64 C-20: http://67-72chevytrucks.com/vboard/s...d.php?t=446527 |

|

|

|

|

|

#93 |

|

Registered User

Join Date: Jul 2011

Location: El Campo, Tx

Posts: 1,246

|

Re: '55 International Metal/Body/Paint Work

It is all looking REAAALLLY good, astro. You have some valuable tips in here for us too that will be useful to many of us in the future. Did you get the homemade lizardskin the way that you wanted it eventually? Also what gun are you shooting the Slick Sand through?

Hmmm you are 920 miles from here, you want another job? Haha

__________________

72 Chevy blue LWB, 99% original Oklahoma truck, 28,000 miles 72 Chevy SWB: http://67-72chevytrucks.com/vboard/s...d.php?t=486626 (Attempt/Mistake #2) 2003 Harley Davidson Dyna Superglide with 2007 Street Bob front end 2000 Ford F350 Powerstroke 4WD CCLB, 310,000 miles running great (STOLEN St. Patricks Day 2014 AND NEVER RECOVERED) 2002 Ford F250 Powerstroke 4WD CCLB (To replace stolen one) Hook em Horns!!! |

|

|

|

|

|

#94 |

|

Old and crusty

Join Date: Jan 2009

Location: Surprise, AZ

Posts: 462

|

Re: '55 International Metal/Body/Paint Work

That's really looking great, John. Are you going to have it done before the snow starts to fly?

__________________

65 Chevy long wide daily driver - SOLD! 64 Chevy Short Step LS |

|

|

|

|

|

#95 | |||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Quote:

Quote:

Quote:

I'm not good at setting and making deadlines; they always run over. I've still got to spray/cut/buff the front clip but it's all ready to spray, just waiting on a dry day to paint them. The cab (already picked up) and doors are done and ready to be bolted up. I still have the whole bed and rear fenders to do though, and I'll probably be making bedsides and the header panel from scratch. I'm not good at setting and making deadlines; they always run over. I've still got to spray/cut/buff the front clip but it's all ready to spray, just waiting on a dry day to paint them. The cab (already picked up) and doors are done and ready to be bolted up. I still have the whole bed and rear fenders to do though, and I'll probably be making bedsides and the header panel from scratch.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|||

|

|

|

|

|

#96 |

|

Registered User

Join Date: Apr 2012

Location: Beaver, Pa.

Posts: 197

|

Re: '55 International Metal/Body/Paint Work

Astronaut, could you give a quick explanation of how you heat shrink metal? Is it a hard technique to learn? Seems like it would handy as around a dent you always have stretched metal. Following this (and all your threads) closely!

|

|

|

|

|

|

#97 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Quote:

It's not hard if you learn to do it the right way- I wasn't taught the right way, so I was frustrated with it at first. I tried shrinking with a torch and wet rag like some people tell you to do, but they leave out the step of using the hammer and dolly to actually flatten and pull the metal inward while the metal is still red hot. That works but has very little shrinking action, and it's easy to warp the metal more than you're actually helping. Or atleast that was my experience. The way I now do it is: Quickly (or else you'll warp a bigger spot from the panel getting too hot) get a spot about the size of a quarter red hot, support the back with a dolly, and hammer around the red spot to draw down the high spot, then you quench the spot with a wet rag. Don't hit any of the red hot area with the hammer, or you'll just add to the amount of stretch. Repeat until the area is flat and isn't popping in and out. If you over shrink you can use the "hammer on dolly" method to stretch the metal. Hitting the hammer directly on the dolly squeezes the metal outwards to stretch it.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#98 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Here were the front clip panel gaps. I was surprised at how well everything fit without any tweaking.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#99 |

|

Registered User

Join Date: Jul 2011

Location: El Campo, Tx

Posts: 1,246

|

Re: '55 International Metal/Body/Paint Work

Looking beautiful as usual. My project that I would literally seriously consider having you work on is the truck in my signature. Long story short but it is sheet metal work only that I need done. The chassis has all been rebuilt. The sheet metal consists of the following: Original paint cab from Arizona, no rust through anywhere, rockers are perfect even, New bedsides (SWB), bed has been assembled but one of the bedsides has a wave in it in front of the front wheel and there are several dents on them, original tailgate (no rust), original hood no rust and straight (off of the same truck as cab came from), one original paint door (no rust and one small dent on the bottom of it) and one aftermarket door that actually fits well, one original paint front fender (minimal rust, nowhere close to rusting through) and one aftermarket fender that also fits well, aftermarket core support and two aftermarket inner fenders. No rust repair anywhere

I am keeping eye out for another original paint door as I REALLLLY like OEM parts versus taiwan crap. The doors I want the handles and mirrors shaved, I will have installed (or mocked up I should say) the one piece windows and the door poppers. I have had such poor luck and gotten screwed by collision body shops that are not passionate about their work and do crappy work with the lower quality products that I would rather take this 1000 miles away and get done by someone who has shown amazing potential than go through that BS again! Especially since you are a forum member and I could splash these pages with your work I am keeping eye out for another original paint door as I REALLLLY like OEM parts versus taiwan crap. The doors I want the handles and mirrors shaved, I will have installed (or mocked up I should say) the one piece windows and the door poppers. I have had such poor luck and gotten screwed by collision body shops that are not passionate about their work and do crappy work with the lower quality products that I would rather take this 1000 miles away and get done by someone who has shown amazing potential than go through that BS again! Especially since you are a forum member and I could splash these pages with your work  Oh yea and the final color is going to be the new Range Rover white. Not trying to take away from this International or your thread! I am anxious for those final paint pictures, I could have sworn I saw some teasers somewhere on here of some liquid looking red paint that was about 10 miles deep. Oh yea and the final color is going to be the new Range Rover white. Not trying to take away from this International or your thread! I am anxious for those final paint pictures, I could have sworn I saw some teasers somewhere on here of some liquid looking red paint that was about 10 miles deep.

__________________

72 Chevy blue LWB, 99% original Oklahoma truck, 28,000 miles 72 Chevy SWB: http://67-72chevytrucks.com/vboard/s...d.php?t=486626 (Attempt/Mistake #2) 2003 Harley Davidson Dyna Superglide with 2007 Street Bob front end 2000 Ford F350 Powerstroke 4WD CCLB, 310,000 miles running great (STOLEN St. Patricks Day 2014 AND NEVER RECOVERED) 2002 Ford F250 Powerstroke 4WD CCLB (To replace stolen one) Hook em Horns!!! |

|

|

|

|

|

#100 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

Re: '55 International Metal/Body/Paint Work

Say what? Can you provide a link to Webster's or Wikipedia with an explanation of that term? I'm having a hard time comprehending that one...

I'd' be up for doing it, but I've got the whole bed to start/finish (likely that I'll be building from scratch) on the '55, and '58 ragtop VW already lined up for metal/body/paintwork. After that I've got a guy that wants me to take the front clip off a couple of his Chevelle's and detail everything under the hood. I've only got room for one at a time, so it'll be quite awhile before I could take on anything else. I'd love to do it though- I'd like to get into doing metalwork only anyways. The body/paint process just takes too long. Here's a few more teaser shots. The first is the reflection of the doors in the roof skin, and the reflection on the doors is a building about 50 feet away.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|