|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Mar 2016

Location: Arizona

Posts: 36

|

Fleetside side panel dented

My son has a '66 Fleetside (short bed) and there is a large dent on the right side in front of the right rear wheel. The dent is approx. 12"x12". The previous owner apparently tried to fix it likely with a slide hammer...it didn't work! I tried to pull it out, but every time I pull it out, it pops back in. I'm no auto body guy, but I do know how to do some basic bodywork and paint (I did my '60 C10 last year). Does anyone know how i can get that dent to stay in place? I've been researching "metal shrinking", but I've never done that. I'm not afraid to try that, I just want to make sure I have a good idea on what I need to do. I did try a slide hammer too, but when I pull the dent out, it'll pop back in once I let off the pressure on the slide hammer. I know the best thing to do is to replace that side panel, but my son's funds aren't allowing him to do that just yet. The truck is not a show truck, but of course we'd like to do the best we can. Thank you in advance.

__________________

1960 C10, shortbed, step side, big back window, 350, Turbo 400 |

|

|

|

|

|

#2 | |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: Fleetside side panel dented

Quote:

Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: Fleetside side panel dented

Basics of Basics” Flat panel repair

By Brian Martin When you have a large flat panel that is flexing the first thing you need to do is find out why. Sometimes you can stop it, other times you can’t. But if you can stop it, you’ll have a much easier time with the body filler work. Hoods, decklids, and the roof are particularly difficult because the heat and weight of the plastic filler can have an effect on the metal. The good news is many times it is very easy to repair. First off, there is no such thing as a “flat” panel. All panels that appear flat actually have a slight crown or gentle bow up in the middle. Go to a flat panel and lay a straight edge across it. You will see that the straight edge in not touching the panel at the on the outer ends. If the panel were perfectly flat it would appear to the eye to be concave. It would also have no “body” and flex very easily. This is the problem with your large flexing panel; it has “lost” its crown and is now weak and flexible. The first place to start your search for a culprit is under the panel. Many panels have inner structure that supports the outer skin. When the outer panel has been damaged the inner structure was bent down along with the outer. This inner structure can be in the form of just a simple inch or so wide support running across the panel to the complete support by a stamped panel that goes covers the underside of the panel. These full inner structures can commonly be found on hoods and decklids. The inner structure can sometimes be bent down, causing your flexing. It usually is very close to the outer skin, with just a thin layer of a foam or urethane adhesive. It may have small “dollops” of this foam or adhesive that has been squished between the inner structure and outer skin or even a thin piece of tarpaper. You can push up on these low spots to return it to supporting the outer skin, as it should. But it is difficult because you can’t push it past where it needs to be. On this particular type of damage, the inner structure would need to go past the correct shape and then “relax” back down to where it belongs. It can’t do this of course because the outer panel is there and limits the inner structure from going up where it needs to go. Just as with looking at the “big picture” when you look at any dent, you need to search for a kink or bend that is holding the inner structure down in that area. If you apply pressure up on the low area and tap out these kinks, you may get it to stay back in shape. If these methods don’t get it back up to support the outer panel properly, you will need to “shim” between the two panels to get the outer panel up where it belongs. This can be done with sheet of tarpaper or more adhesive. As a last resort a thin piece of wood like a paint stirring stick can be used. Of course, this is a little on the funky side but if you are haven’t been able to correct the problem, something has to be done. What you have to watch out for is applying too much pressure in one area. If you were to force a piece of wood in there, you will likely be making a high spot on the outside. That would just give you in a whole new problem. Sight down the body lines that are nearest the low, “oil canning” , or just plain flexing area. A body line is effectively the “edge” of the panel. Those crowns in the flat panel that I mention end at the body line. So each area in between the lines is sort of like an individual panel. Look to see if the body line is low, it may be holding down your panel. If it is, you need to push it up. To help you determine how straight the line is sometimes you can use a metal ruler as a “straight edge”. How can this be done on a crowned panel you ask? A metal carpenters yard stick will bend very easily, right? So what you do is lay the yard stick on it’s back against the panel and apply a little pressure on the outward edges low area where the metal is OK. You will then have a “curved straight edge”. I have a drawer with a number of these metal or aluminum rulers in it and find them very useful. I treat them like rice paper and they will last a lifetime. So lets say that you have found that you have no low spots in the body lines or there were one or two and you repaired them. Now you have to look for something else that is holding the panel down. This can usually be found in the form of a “crown” or “brow”. When you put a dent in any panel the metal has to “go” somewhere. All panels have this crown, right? So as an example picture a metal rod that is 3 feet long. This rod has a slight bend to it. The center of the rod is up from the ends about three inches. If you were to push down on the center, the rod would get “longer”, right? So, if the ends of the rod were clamped in vices, the “extra” rod would force the areas on the sides of where you were pushing to go up. You panel does the same thing only on a much smaller scale. Most brows will be found on the outer edges of a panel, this includes of course at the edge of the body line. They are VERY common around the outer edges of a roof. Search around the outer edges of ANY bent roof and you will find them. The brow or crown is a U, C, L or even I shaped high spot. In the center of that curved high spot is a low spot, sort of like a “pocket” in the brow. Just one or two of these will make a panel, especially a large panel look like a cotton sheet! What you have to do is to push up on that low spot while tapping down on the brow. When I say “tap” I mean TAP. Just the weight of the hammer bouncing off the brow will do it sometimes. Use a large VERY flat body hammer or a flat body spoon for this repair. If you are careful you can repair these brows with little to no plastic filler. Just take you time and keep checking the area with a block with sand paper or a vexon file if you have one for low and high spots. Now, if you simply can eliminate the brow and low spot, you have won the battle. If it takes some plastic filler, so be it, you have given the panel it’s strength back and that is what matters.

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Mar 2016

Location: Arizona

Posts: 36

|

Re: Fleetside side panel dented

Thank you for the info Martinsr! I'll check into that. So, if/when I find the crown, I use something (like the slide hammer) to pull on the dent and at the same time tap the crown with the body hammer? Makes sense to me! I'll report back tonight or tomorrow when I do this. Thank you again...

__________________

1960 C10, shortbed, step side, big back window, 350, Turbo 400 |

|

|

|

|

|

#5 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,581

|

Re: Fleetside side panel dented

got any pics?....it might help if it can be seen

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Mar 2016

Location: Arizona

Posts: 36

|

Re: Fleetside side panel dented

I hope these two pics worked! Sorry for the poor lighting. I didn't see any obvious crowns. I did pull the dent out and hammered around the top and bottom of the dent hoping it would do something...but no luck. Do you guys see any crowns in the pics? The larger holes up top are for the trim. The machine-gun looking holes were from the previous owner's try at the dent. I'm not bagging on him at all, heck I would have tried the same thing.

__________________

1960 C10, shortbed, step side, big back window, 350, Turbo 400 |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Mar 2016

Location: Arizona

Posts: 36

|

Re: Fleetside side panel dented

Also, the little marks above and below the dent are from me trying to hammer while I pulled on the dent.

__________________

1960 C10, shortbed, step side, big back window, 350, Turbo 400 |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: Fleetside side panel dented

Well, it's damn hard to tell you what to do without being there. It does look over worked, welding the holes up would tighten it up a bit as each weld cools. DO NOT cool them with water or air unless you KNOW they need to be shrunk even more and there is no way one of us could tell you with the info we have. But just welding and letting them cool will shrink it a bit. And if you do this, do them one at a time and let them cool completely before you weld the next one.

Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Mar 2016

Location: Arizona

Posts: 36

|

Re: Fleetside side panel dented

Thanks Brian, I like that idea about welding those holes up one at a time. Does it make a difference if I weld the hole/s on the outside apposed to welding the center holes first? I'll do this tomorrow morning.

__________________

1960 C10, shortbed, step side, big back window, 350, Turbo 400 |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Sep 2016

Location: Titonka, IA

Posts: 112

|

Re: Fleetside side panel dented

I don't know if you know this trick or not, but if you take a piece of copper pipe and crush the end of it so it's flat, it makes a really good backer for welding those holes shut. Helps you keep from burning through.

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: Fleetside side panel dented

And of course if you plannish it flat it will likely close the hole up. Often back int he day, the hole wasn't drilled out for the slide hammer, it was punched with an awl.

Brings back a memory, I was about 18 at my first full time job doing body repair on used cars for a dealership, this was 1977. We got in a 71ish Monte Carlo with a real pearl white paint job. It had one large dent on the front fender between the wheel well and the door. Right off the bat we wouldn't be painting it being we didn't know a thing about pearls. So I would fix the dent and it would go for a complete at "Miracle auto painting" (a McPaint shop) in plain white. I drilled a hole in the dent to pull with the slide hammer and in one tiny pull it popped right out! LOLOLOLOL It popped out without a hardly a fraction of a brow or something on the edge. But now it had a hole drilled! LOL I had to bondo over the hole and we sent it for a complete paint job over that beautiful pearl. LOL I could have used a suction cup or pushed it from the inside and popped that dent right out and sent it back to the dealer done! Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#12 |

|

Lost amongst the CORN

Join Date: Nov 2002

Location: Northern Iowa

Posts: 1,072

|

Re: Fleetside side panel dented

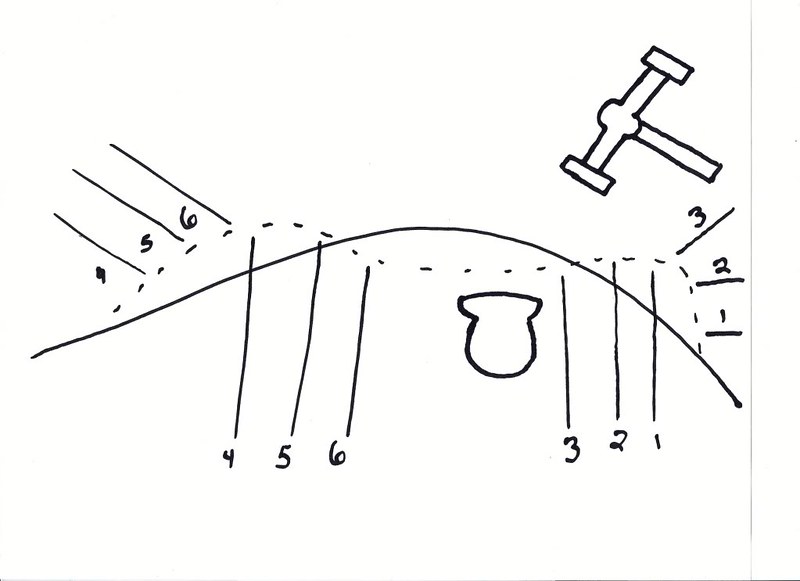

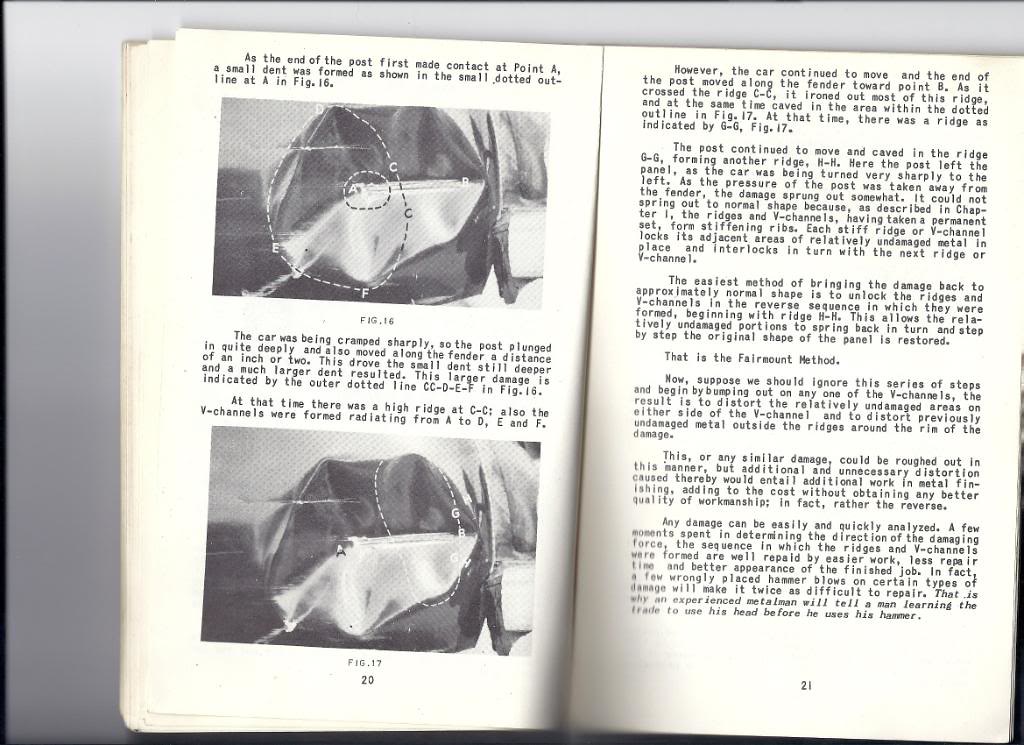

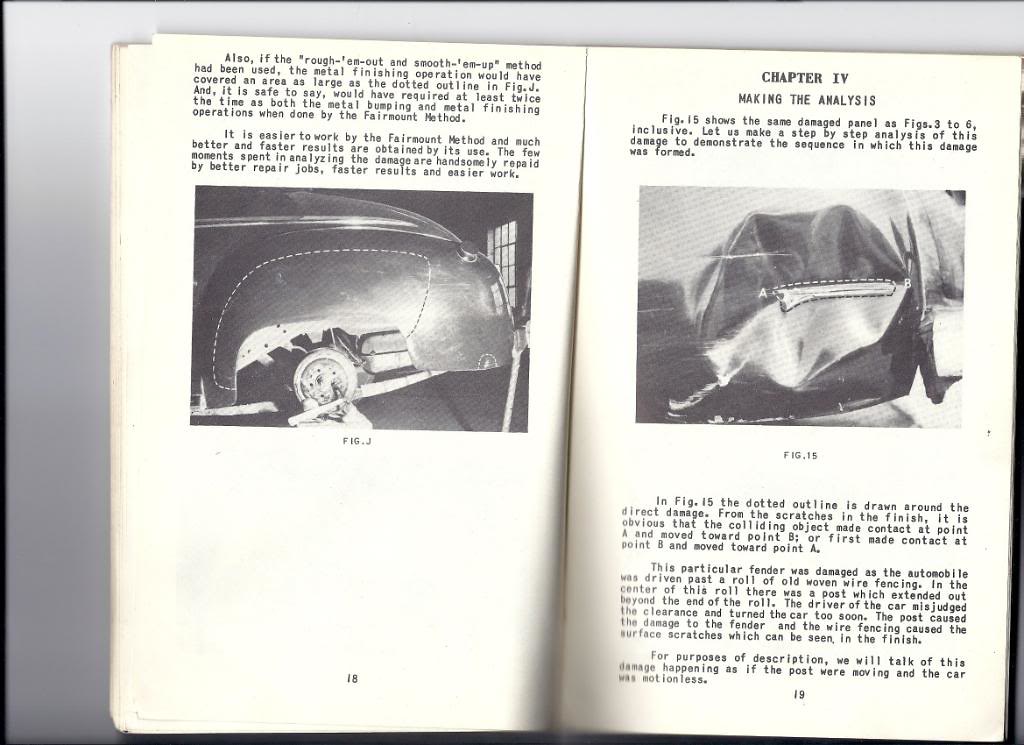

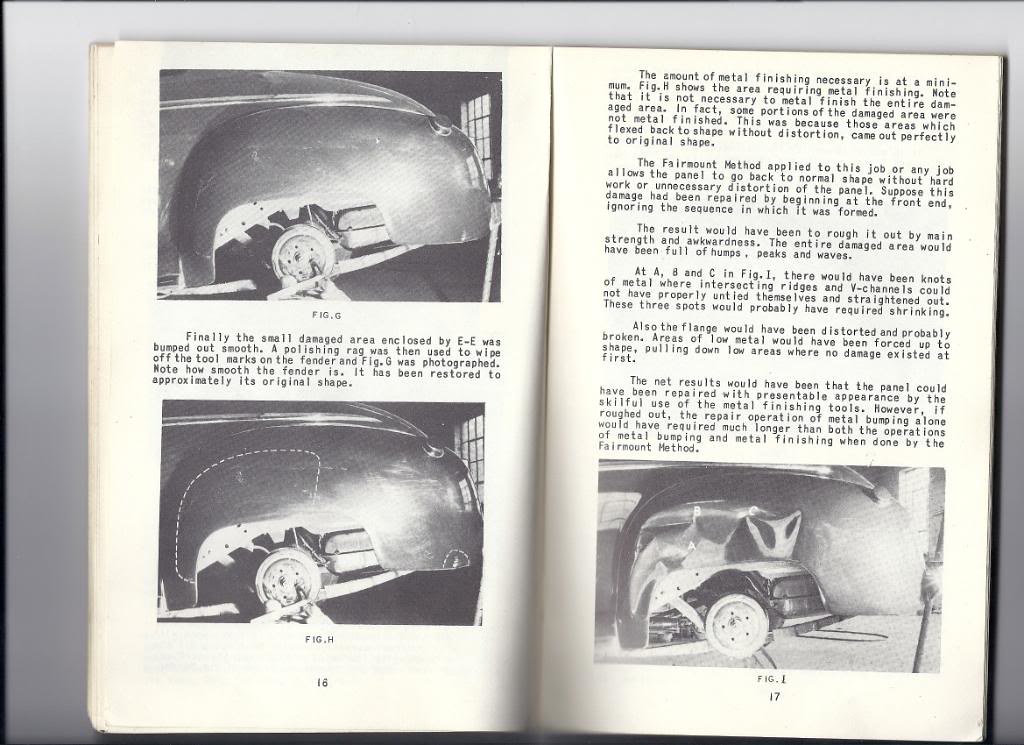

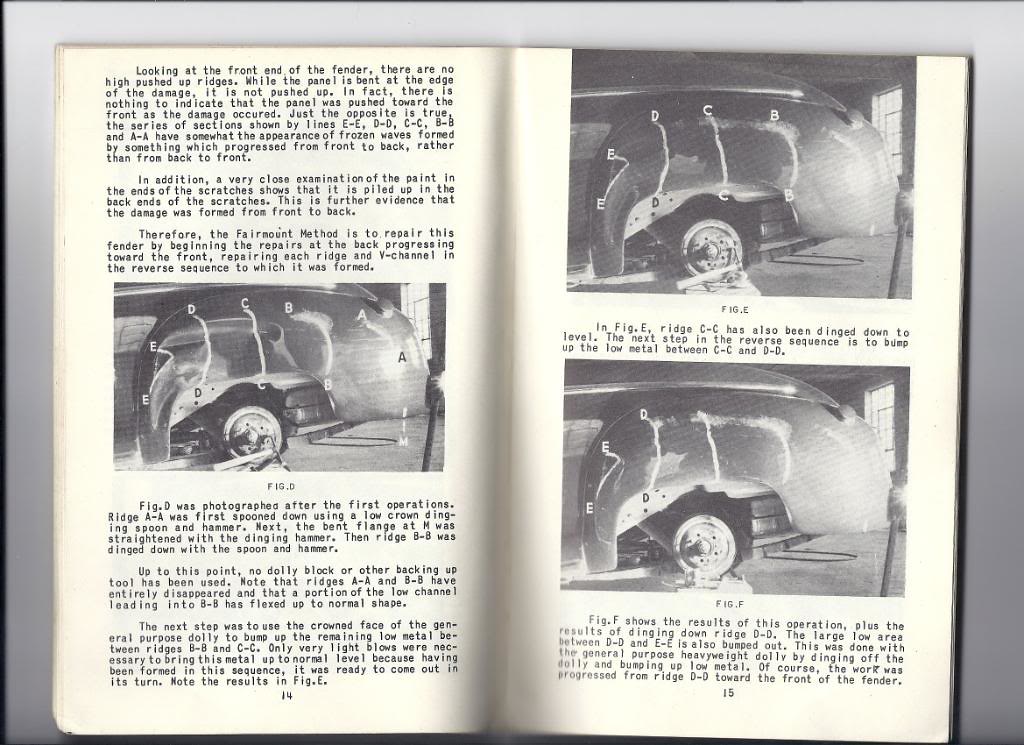

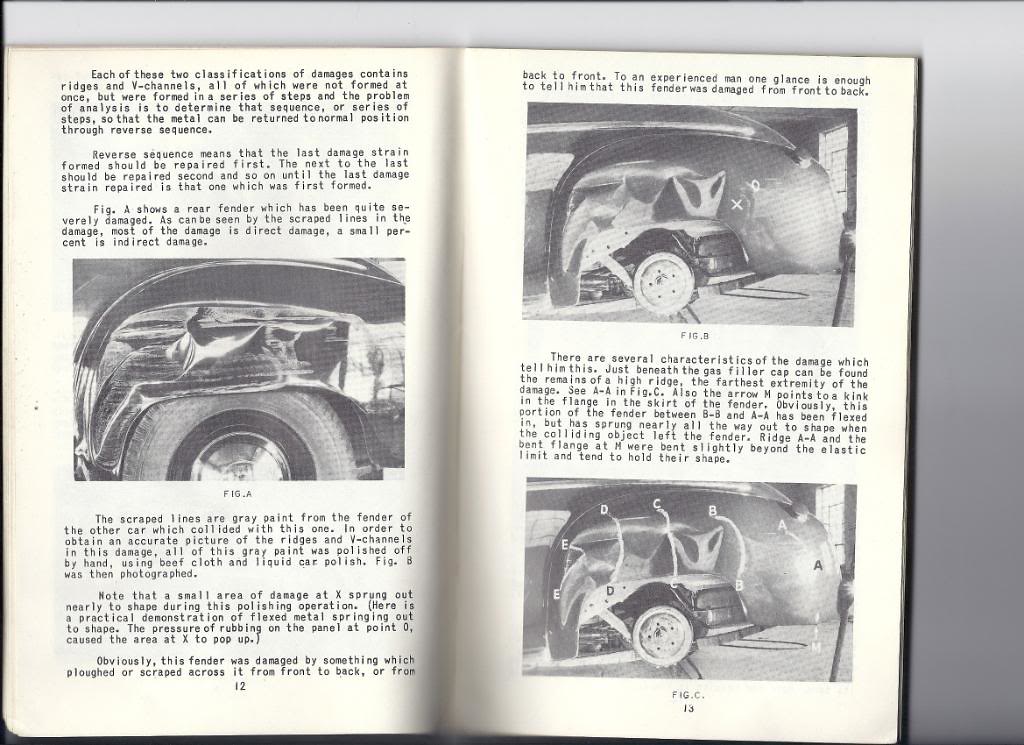

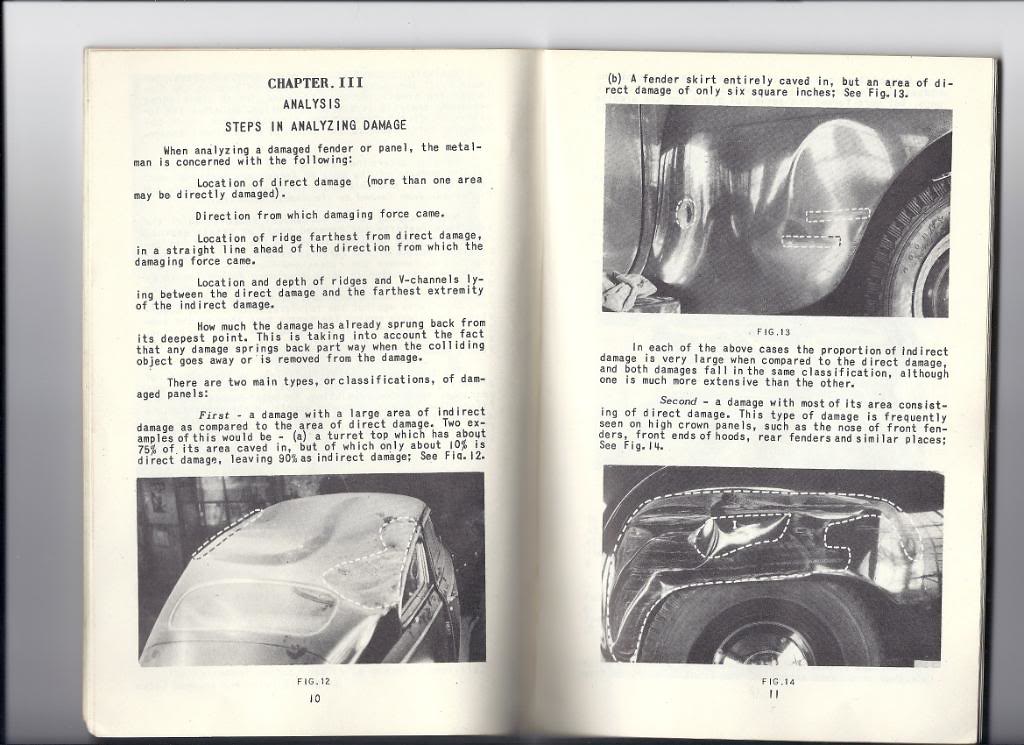

IMO you need to work on smoothing out the metal first before welding up the holes. If you can't visualize the damage and most people can't, go down to office depot and buy yourself a magnum magic marker. Take said marker and ink the entire damaged area. Now take a sanding block with say 180 grit and block the panel.

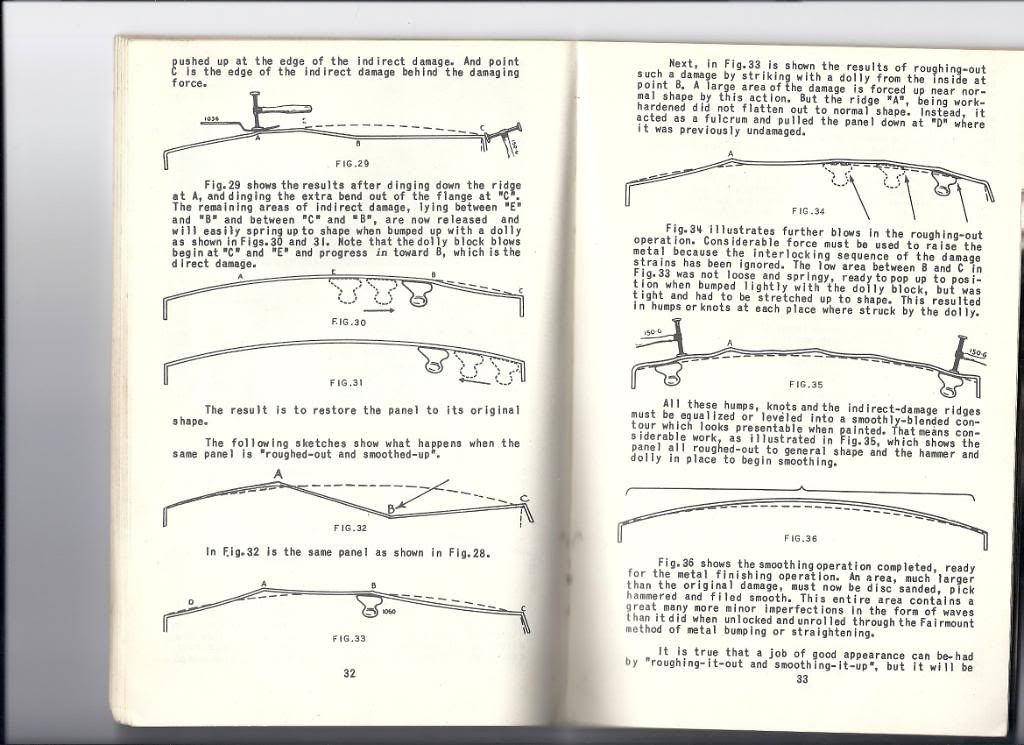

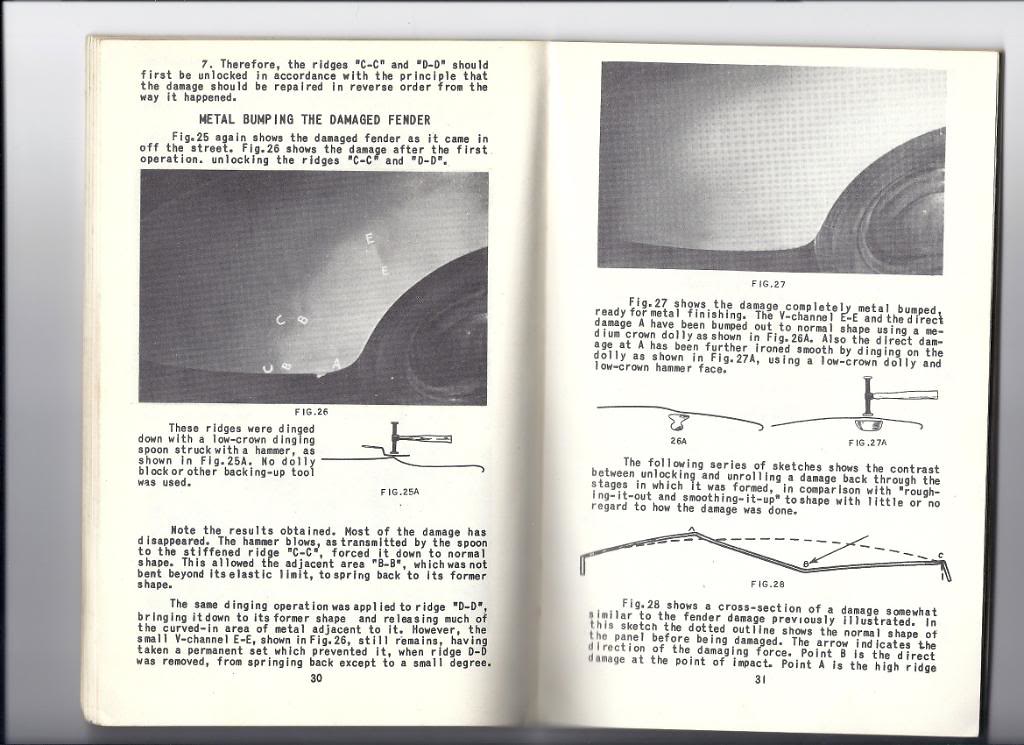

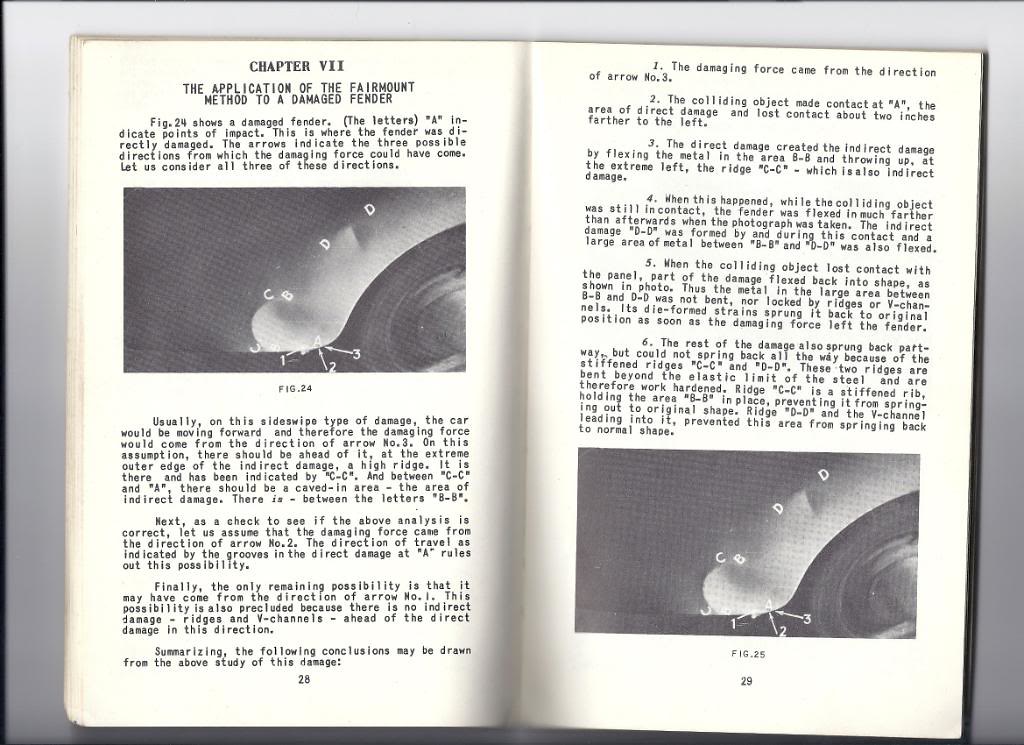

Your results will then look like this.  2003_0101Image0007 by eric2406, on Flickr 2003_0101Image0007 by eric2406, on FlickrThis is hammer on dolly, it will stretch out the metal.  hammerondollypic by eric2406, on Flickr hammerondollypic by eric2406, on Flickr This is hammer off dolly. This is what I would be using to smooth out the metal. The hammer and dolly are never in direct contact so stretching is limited.  hammeroffdollypic by eric2406, on Flickr hammeroffdollypic by eric2406, on FlickrKinda the basic path of dent repair.  Scan_Pic00031 by eric2406, on Flickr Scan_Pic00031 by eric2406, on FlickrScanned pics from the 1st edition of the Keys of metal bumping by Frank Sargent...1933 if I remember right. Pics are out of order but you can follow the page numbers.  Scan_Pic0025 by eric2406, on Flickr Scan_Pic0025 by eric2406, on Flickr Scan_Pic0024 by eric2406, on Flickr Scan_Pic0024 by eric2406, on Flickr Scan_Pic0023 by eric2406, on Flickr Scan_Pic0023 by eric2406, on Flickr Scan_Pic0022 by eric2406, on Flickr Scan_Pic0022 by eric2406, on Flickr Scan_Pic0021 by eric2406, on Flickr Scan_Pic0021 by eric2406, on Flickr Scan_Pic0020 by eric2406, on Flickr Scan_Pic0020 by eric2406, on Flickr Scan_Pic0019 by eric2406, on Flickr Scan_Pic0019 by eric2406, on Flickr Scan_Pic0018 by eric2406, on Flickr Scan_Pic0018 by eric2406, on Flickr Scan_Pic0017 by eric2406, on Flickr Scan_Pic0017 by eric2406, on FlickrAm also of the opinion that body hammers in the hand of the unskilled can cause more damage. I use a slap hammer probably 99% of the time doing dent repair. The surface area is larger, more forgiving and IMO just a superior method then a body hammer. You can make a slapper out of a old leaf spring. The slapper on left is a slapper I bought from Covell.biz many years ago, the larger slapper I made from a F250 leaf spring.  mostusedtools by eric2406, on Flickr mostusedtools by eric2406, on Flickr

__________________

Currently working on How To Videos and custom metal 70 Chevelle gettin Sliced and Diced Anything But STOCK 70 Chevelle SS455 not a typo its a BUICK BABY 49 and 72 Chevy Trucks restored to original...close to it Drommer Stor....Norwegian for Dream Big http://s969.photobucket.com/albums/a...lle/?start=all https://www.flickr.com/photos/47922830@N03/ Pictures of my work and projects Last edited by sevt_chevelle; 06-06-2018 at 06:40 PM. |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: Fleetside side panel dented

Wow, I was trying to cut to the chase.

If you want to really learn something, go with Sevt's post. Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#14 |

|

Kung Fu Master

Join Date: Oct 2005

Location: Montana

Posts: 543

|

Re: Fleetside side panel dented

IMO, both of you offer excellent advice all the time!

__________________

72 GMC SuperCustom 4x4 1972 Chevrolet Cheyenne Super 4x4 |

|

|

|

|

| Bookmarks |

|

|