|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#26 |

|

Senior Member

Join Date: Aug 2004

Location: Centennial, CO

Posts: 2,882

|

Re: A/C reached critical mass!

Nice work, I have the same POA system in my 68 caddy and had to play around with the fill level. 80% was too much, the hi side was way up there.

Like you, I did somewhere around 60-70% and it works well. Your idling conditions will mimic what it's like to be stuck in traffic, so I'd see how it does.

__________________

ClusterTruck: 68 C10 Bought in 89, wrecked in 03. Slow low $ rebuild started '17. 6.0 & TKO http://67-72chevytrucks.com/vboard/s...d.php?t=788602 93 K1500 Short Step, 350, NV4500, EBL flash ECU. Vortec heads & roller cam someday... 05 Jeep Wrangler Unlimited. 3” lift & 6-speed 02 E320 the insurance total “free car” 13 Tahoe LTZ |

|

|

|

|

|

#27 |

|

Registered User

Join Date: Feb 2012

Location: Smyrna TN

Posts: 1,153

|

Re: A/C reached critical mass!

Thanks Clay. Its still not right. The high side pressure is going above 300 at idle. I'm going to replace the POA and expansion valve. I'll update once thats done, probably be a week or so. Nothing is ever easy on this truck:-)

__________________

1971 Longbed BB Cheyenne Super 1972 Longbed SB Cheyenne Super 1972 Longbed Highlander Custom Deluxe 1975 K5 4x4 full convertible Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=645165 Greg Smyrna TN |

|

|

|

|

|

#28 |

|

Old member

Join Date: Jan 2002

Location: Liberty, & Garden City S.C. , U.S.

Posts: 19,936

|

Nice write up on your system and what you did.

One thing a lot of people don't understand about AC is that the more air you move across the condenser at any given time is how you get colder air into the cab. So if your sitting in your garage idling and you get down to 40* you are as good as you need it. If you start dipping into the 30's then it's going to freeze up on you. 38* to 40* is where I say you need to be and it will be fine once your going down the high way. This is why I like to run a fan off of the AC switch. To get the most air effect that I can. This is the reason you see vehicles ac temps go up sitting at a light. My truck can sit for a long time with the ac running and it stays right at 190* water temp and AC blowing at 38* to 40* no matter what the outside temp is. I also run my AC fan through a micro switch mounted out on the front of the grille to cut the fan off at road speed which is 25MPH. This gives me longer fan life and it's not needed when the vehicle is moving. Another small thing is sealing the radiator off forcing the air to go through it instead of around it. 225 to 250 is what you should have on the high side gauge at 85* air temp.45-55 PSI on the low side at 85* give are take a little either way.Get it close and see how it sweets if it's sweeting good and making a nice puddle of water leave it alone.

__________________

1971 LWB Custom, 6.0LS & 4L80E, Speedhut.com GPS speedometer & gauges with A/C. 20" Boss 338's Grey wheels 4 wheel disc brakes. My Driver Seeing the USA in a 71  Upstate SC GM Truck Club 2013,14 and 2016 Hot Rod Pour Tour http://upstategmtrucks.com/ Get out and drive the truck this summer and have some fun! It sucks not being able to hear! LWB trucks rule, if you don't think so measure your SWB! After talking to tech support at Air Lift I have found out that the kit I need is 60811. Per the measurements I gave them. Ride height of truck inside spring and inside diameter of springs. Last edited by Andy4639; 06-26-2017 at 09:46 PM. |

|

|

|

|

|

#29 |

|

Registered User

Join Date: Feb 2012

Location: Smyrna TN

Posts: 1,153

|

Re: A/C reached critical mass!

Thanks Andy. I'm just really perplexed as to why both low and high side pressures are so high. With the truck completely cool the pressures are good when first started and within a couple of minutes rise above 60 on the low side and above 300 on the high side. I even tried another set of gauges to make sure I was getting accurate readings.

__________________

1971 Longbed BB Cheyenne Super 1972 Longbed SB Cheyenne Super 1972 Longbed Highlander Custom Deluxe 1975 K5 4x4 full convertible Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=645165 Greg Smyrna TN |

|

|

|

|

|

#30 |

|

Senior Member

Join Date: Mar 2005

Location: Jurupa Valley, Ca

Posts: 1,209

|

Re: A/C reached critical mass!

I've got a similar post going on this subject. Following your progress as it seems to mirror mine.

__________________

Terry 1970 Custom Camper/C20 , GM Crate 350/7004R, Dana 60, factory AC |

|

|

|

|

|

#31 | |

|

Old member

Join Date: Jan 2002

Location: Liberty, & Garden City S.C. , U.S.

Posts: 19,936

|

Quote:

If you have a good size shop fan get the truck up to normal temp and then cut the fan on to see what it does. This will act like going down the road and the gauges should drop a little due to the heat transfer of the coils. The POA valve could be off just a touch also. If the POA is sweeting good and the puddle of water it creates is a good amount under the truck I'd call it good though.

__________________

1971 LWB Custom, 6.0LS & 4L80E, Speedhut.com GPS speedometer & gauges with A/C. 20" Boss 338's Grey wheels 4 wheel disc brakes. My Driver Seeing the USA in a 71  Upstate SC GM Truck Club 2013,14 and 2016 Hot Rod Pour Tour http://upstategmtrucks.com/ Get out and drive the truck this summer and have some fun! It sucks not being able to hear! LWB trucks rule, if you don't think so measure your SWB! After talking to tech support at Air Lift I have found out that the kit I need is 60811. Per the measurements I gave them. Ride height of truck inside spring and inside diameter of springs. |

|

|

|

|

|

|

#32 |

|

Moderator

Join Date: May 2007

Location: Southern Cal

Posts: 19,981

|

Re: A/C reached critical mass!

In addition to using a box fan, you can mist water from a spray bottle across the condenser for better heat transfer. Watch your gauges as you do this, the pressures drop instantly

__________________

1972 C/10 Cheyenne Super SWB. Restored, loaded, slammed. 1968 C/10 50th Anniversary LWB. Unrestored, stock, daily driver/work truck. RIP ElJay RIP 67ChevyRedneck RIP Grumpy Old Man |

|

|

|

|

|

#33 |

|

Registered User

Join Date: Feb 2012

Location: Smyrna TN

Posts: 1,153

|

Re: A/C reached critical mass!

leddzepp has advised all of us numerous times that R134a doesn't work well in our trucks, he is 100% right. Andy, I tried the box fan and it helped. As bad as I hated to strap a pusher fan on my brand new condenser, I did. HOLY CRAP batman, what a difference. High side never went above 275 even after running for 25-30 minutes at ~1400 rpm's. So my stubborn ass that insisted on R134a, will now admit that I will have to run a pusher fan. If not, I'm fairly certain that if I have to idle at a long red light in 95-100 degree weather or get stuck in stop and go traffic the high side pressure will evenly reach critical mass and something will break. I will add the filler panels to help with air flow as well. By the way I'm running dual 1600cfm electric fans (puller) on my radiator that sounds like a jet taking off. I'm sure they move much more air than the stock fan with a clutch.

__________________

1971 Longbed BB Cheyenne Super 1972 Longbed SB Cheyenne Super 1972 Longbed Highlander Custom Deluxe 1975 K5 4x4 full convertible Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=645165 Greg Smyrna TN |

|

|

|

|

|

#34 |

|

Registered User

Join Date: Apr 2007

Location: pasadena,TEXAS

Posts: 880

|

Re: A/C reached critical mass!

Nice write up. Pics were nice also having pics to go by makes a job go better.

Was the compressor you got from the zone an a6? Is it workin ok? Mine is slinging oil out the front and I think it needs to be replaced. All the work I did and it is still not getting as cold as it should!

__________________

1971 Cheyenne SWB 402BB, 700R4, 3.73 posi, PS, PB, A/C, Tilt, Tach "Wanda" Don't argue with idiots, People watching may not be able to tell the difference... There's someone in my head........But it's not me...... cheap tricks thread great info here!! http://67-72chevytrucks.com/vboard/s...d.php?t=489394 Last edited by hdff; 06-28-2017 at 10:42 PM. |

|

|

|

|

|

#35 | |

|

Old member

Join Date: Jan 2002

Location: Liberty, & Garden City S.C. , U.S.

Posts: 19,936

|

Quote:

I swapped out the evaporator and condenser for 134-A Freon compatibility and added the orifice tube and accumulator as you can see in the picture. This has been in my truck since the 90's and it works great. Glad you got it cooling though it's always nice to have AC if you want it are need it. Another small trick is to close off the cowl vent good and open the passenger side kick panel vent and let it keep cooling the cab air down.

__________________

1971 LWB Custom, 6.0LS & 4L80E, Speedhut.com GPS speedometer & gauges with A/C. 20" Boss 338's Grey wheels 4 wheel disc brakes. My Driver Seeing the USA in a 71  Upstate SC GM Truck Club 2013,14 and 2016 Hot Rod Pour Tour http://upstategmtrucks.com/ Get out and drive the truck this summer and have some fun! It sucks not being able to hear! LWB trucks rule, if you don't think so measure your SWB! After talking to tech support at Air Lift I have found out that the kit I need is 60811. Per the measurements I gave them. Ride height of truck inside spring and inside diameter of springs. |

|

|

|

|

|

|

#36 |

|

Registered User

Join Date: Feb 2012

Location: Smyrna TN

Posts: 1,153

|

Re: A/C reached critical mass!

hdff the compressor is an A6. Less than an hour of run time so we will see if the front seal holds up. In my humble opinion the high side pressure going above 300 (at idle at a red light or in traffic) is bound to eventually break something, i.e. the front seal on the compressor probably being the weakest link. With a POA or even a POA eliminator kit, expansion valve, and the stock size condenser (even a new one from Old Air Products) there is just not enough air flow to keep the pressures down. Im hoping that the added pusher fan wired to come on any time the compressor is engaged will add some life to the system. I'm going to add filler panels to help as well. If you were to use R12 all these issues go away as it works with much lower pressures.

Andy; "I swapped out the evaporator and condenser for 134-A Freon compatibility and added the orifice tube and accumulator as you can see in the picture". You actually did more, you added filler panels, you are using a smaller aluminum compressor that is much more efficient than an A6 (also much less weight) and with the accumulator (pressure switch) you added the ability to cycle the compressor if/when pressures increase and to prevent evaporator freeze up. You've basically modernized your setup so it's much more efficient. Nice setup by the way! So IMHO, my .02 cents, for what its worth. If I stay with R134a I'll have to accept the fact that its just not going to work as well as R-12 with my current setup. If I'm willing to modernize by adding the later model accumulator pieces/parts and more efficient compressor, etc. it will work as well as R-12. Or I can always move where the temperatures don't reach 90+ degrees with humidity at 80+%:-)

__________________

1971 Longbed BB Cheyenne Super 1972 Longbed SB Cheyenne Super 1972 Longbed Highlander Custom Deluxe 1975 K5 4x4 full convertible Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=645165 Greg Smyrna TN |

|

|

|

|

|

#37 | |

|

Old member

Join Date: Jan 2002

Location: Liberty, & Garden City S.C. , U.S.

Posts: 19,936

|

Quote:

One thing to check on the A-6 compressor also is the air gap at the clutch it needs to be set right are it will soon fail. There should be directions in the box are well at least 20 years ago they had to be!

__________________

1971 LWB Custom, 6.0LS & 4L80E, Speedhut.com GPS speedometer & gauges with A/C. 20" Boss 338's Grey wheels 4 wheel disc brakes. My Driver Seeing the USA in a 71  Upstate SC GM Truck Club 2013,14 and 2016 Hot Rod Pour Tour http://upstategmtrucks.com/ Get out and drive the truck this summer and have some fun! It sucks not being able to hear! LWB trucks rule, if you don't think so measure your SWB! After talking to tech support at Air Lift I have found out that the kit I need is 60811. Per the measurements I gave them. Ride height of truck inside spring and inside diameter of springs. |

|

|

|

|

|

|

#38 | |

|

Registered User

Join Date: Apr 2007

Location: pasadena,TEXAS

Posts: 880

|

Re: A/C reached critical mass!

Quote:

__________________

1971 Cheyenne SWB 402BB, 700R4, 3.73 posi, PS, PB, A/C, Tilt, Tach "Wanda" Don't argue with idiots, People watching may not be able to tell the difference... There's someone in my head........But it's not me...... cheap tricks thread great info here!! http://67-72chevytrucks.com/vboard/s...d.php?t=489394 Last edited by hdff; 06-28-2017 at 10:54 PM. |

|

|

|

|

|

|

#39 | |

|

Old member

Join Date: Jan 2002

Location: Liberty, & Garden City S.C. , U.S.

Posts: 19,936

|

Quote:

__________________

1971 LWB Custom, 6.0LS & 4L80E, Speedhut.com GPS speedometer & gauges with A/C. 20" Boss 338's Grey wheels 4 wheel disc brakes. My Driver Seeing the USA in a 71  Upstate SC GM Truck Club 2013,14 and 2016 Hot Rod Pour Tour http://upstategmtrucks.com/ Get out and drive the truck this summer and have some fun! It sucks not being able to hear! LWB trucks rule, if you don't think so measure your SWB! After talking to tech support at Air Lift I have found out that the kit I need is 60811. Per the measurements I gave them. Ride height of truck inside spring and inside diameter of springs. |

|

|

|

|

|

|

#40 |

|

Registered User

Join Date: Jan 2011

Location: Townsend MT

Posts: 1,725

|

Re: A/C reached critical mass!

A couple things I have observed about these trucks as well as A6 compressor's in general:

1. When converting from R12 to R134a - R134 can cool every bit as well as R12, you just have to have a much larger/more efficient condenser. 2. There is no set conversion for determining how much R134 to put in an R12 system. Most of the time it is in that 70 - 80% range but I have seen as little as 50% and as high as 90%. 3. If you want a good A6 compressor, get one from John Deere. If you don't, any chain store compressor WILL fail in less than 250 hours. Either get a John Deere reman compressor or just switch to a Sanden. Also, you can order a bottle of R12 from most any chain store. It might not be cheap, but it is available. |

|

|

|

|

|

#41 | |

|

Registered User

Join Date: Apr 2007

Location: pasadena,TEXAS

Posts: 880

|

Re: A/C reached critical mass!

Quote:

What chain sells r12?

__________________

1971 Cheyenne SWB 402BB, 700R4, 3.73 posi, PS, PB, A/C, Tilt, Tach "Wanda" Don't argue with idiots, People watching may not be able to tell the difference... There's someone in my head........But it's not me...... cheap tricks thread great info here!! http://67-72chevytrucks.com/vboard/s...d.php?t=489394 |

|

|

|

|

|

|

#42 |

|

Registered User

Join Date: Feb 2012

Location: Smyrna TN

Posts: 1,153

|

Re: A/C reached critical mass!

The 72 I have has a sanden compressor. It was bad when I bought the truck; I believe the compressor was run with low freon. The PO has the 134a conversion done at some shop in GA. The conversion consisted of the sanden compressor, new main line with muffler, and freon. I replaced with a new compressor, vacuumed, and charged with oil and freon. It works no better than the A6 but is much smaller and lighter. The biggest problem I see is that there is no way to protect the compressor from low freon and the system does have a small leak. I don't drive the truck, it sits in storage waiting for restoration. Its my retirement truck project.

__________________

1971 Longbed BB Cheyenne Super 1972 Longbed SB Cheyenne Super 1972 Longbed Highlander Custom Deluxe 1975 K5 4x4 full convertible Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=645165 Greg Smyrna TN |

|

|

|

|

|

#43 |

|

Registered User

Join Date: Dec 2013

Location: Omaha NE

Posts: 620

|

Re: A/C reached critical mass!

Great info!

__________________

1972 C10 Custom Deluxe LWB, 402/400, PS, PB, A/C, Highlander, Hugger / White 1971 C10 Cheyenne LWB (SWB), 350/350, PS, PB, A/C, Dark Olive / White. |

|

|

|

|

|

#44 |

|

Registered User

Join Date: Apr 2010

Location: So Cal

Posts: 1,413

|

Re: A/C reached critical mass!

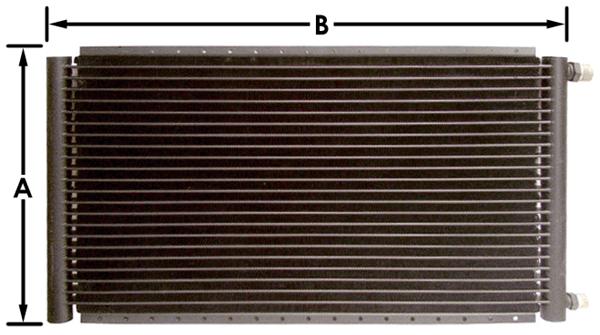

>>Update; pictures of Old Air Products condenser. I placed the new one on top of the original condenser so it would be easier to see size and comparison of the two.<<

Where or who did you actually get that new condenser from? Both your old and new condensers are Tube & Fin design. I don't see any of those on Old Air's web page, although some of their images are poor. You should have chosen a new style Parallel Flow condenser. They are easily identified by the tanks on both ends. When you read about more efficient condensers, this is what they are talking about.

__________________

'67 GMC 2500, 292, 4spd, AC |

|

|

|

|

|

#45 |

|

Registered User

Join Date: Feb 2012

Location: Smyrna TN

Posts: 1,153

|

Re: A/C reached critical mass!

Richard, I called and spoke with Old Air Products. The part number for the condenser is 11-7201, its $220. I ordered it in May of this year.

__________________

1971 Longbed BB Cheyenne Super 1972 Longbed SB Cheyenne Super 1972 Longbed Highlander Custom Deluxe 1975 K5 4x4 full convertible Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=645165 Greg Smyrna TN |

|

|

|

|

| Bookmarks |

|

|