|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Unity Spotlight Repairs

Enthusiasts wanting to rebuild or repair a vintage Unity spotlight may find this post informative or interesting. Everyone else might prefer to leave now or risk being bored to tears. It’s a collection of what I’ve learned and experienced over several decades of putting junk yard dogs back into service.

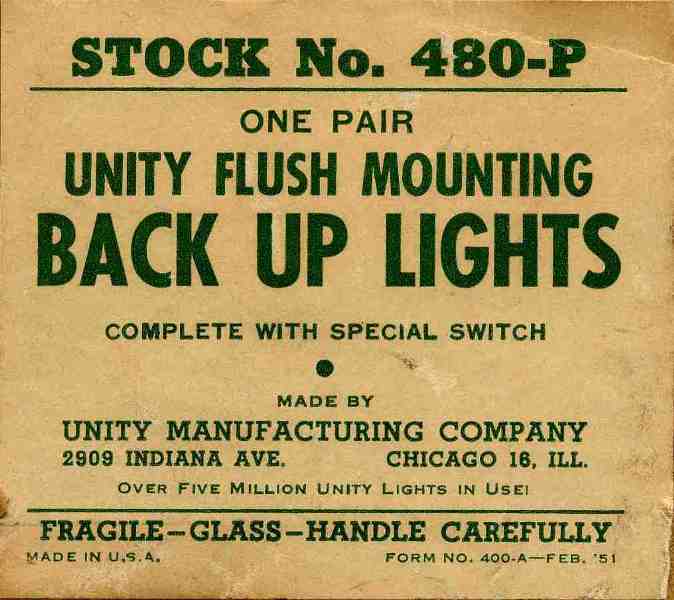

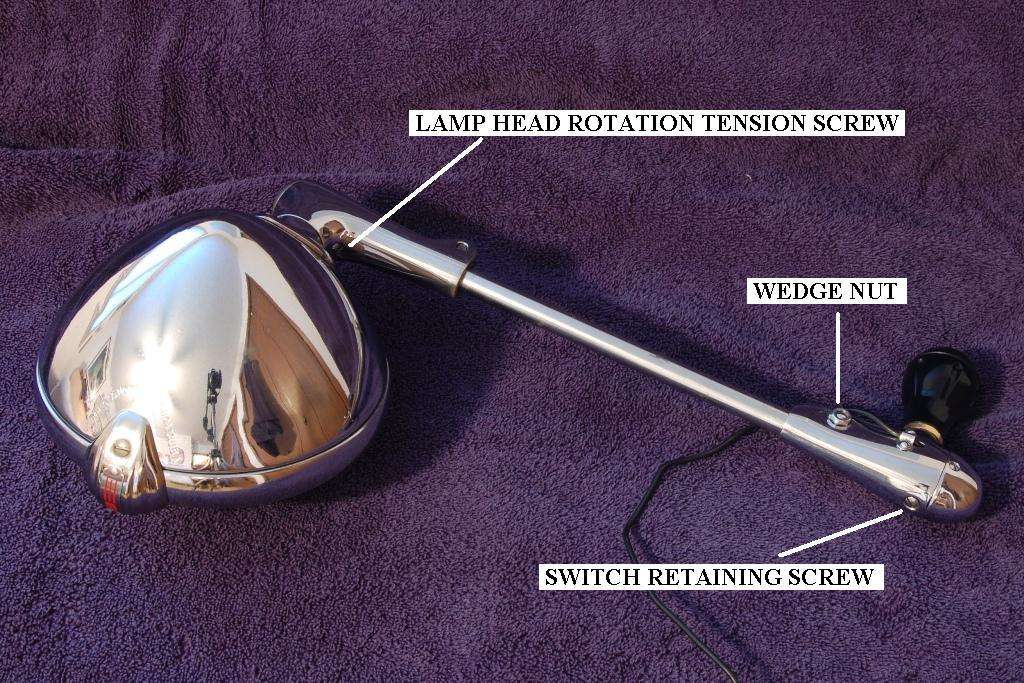

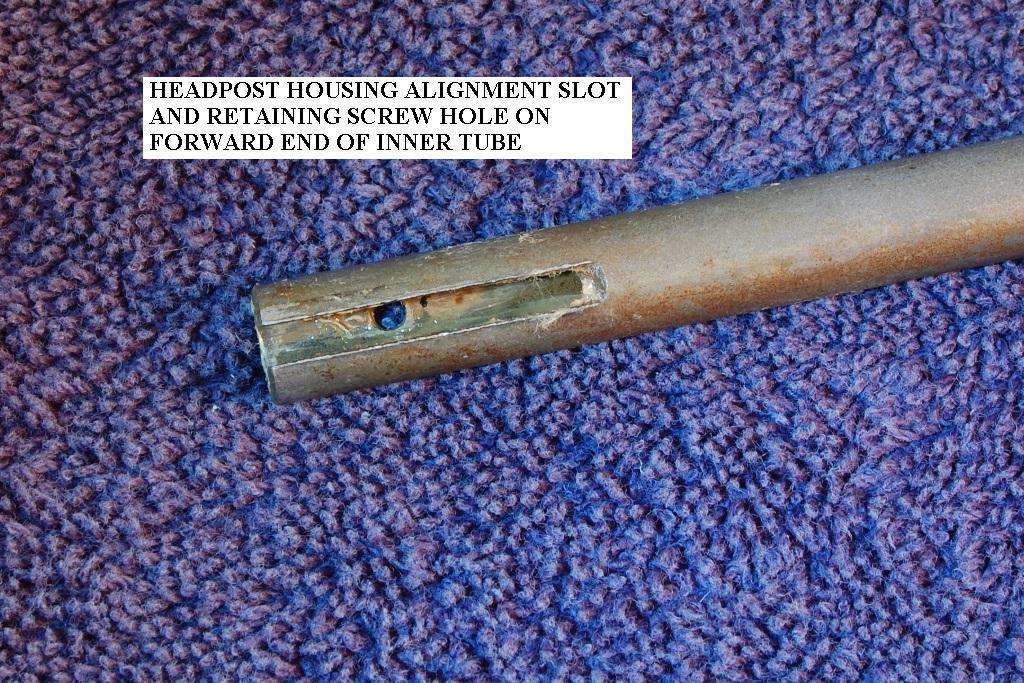

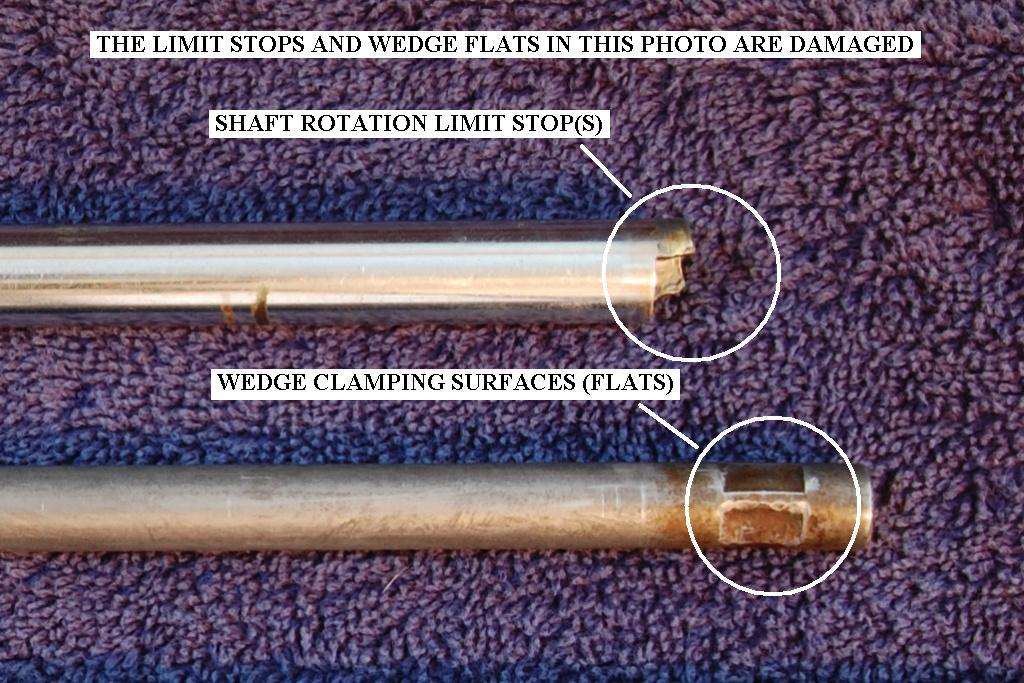

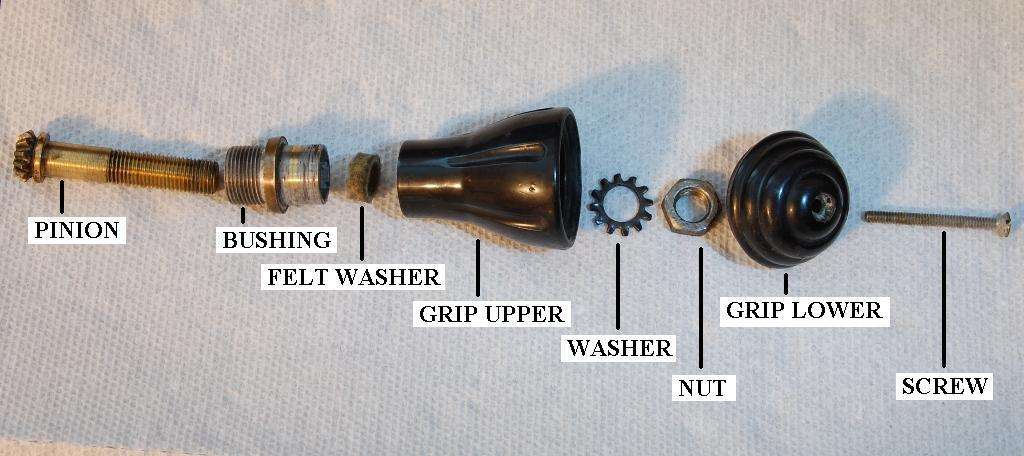

The Unity spotlight has been the standard of commercial industry at least since the 1940’s. Thousands (if not millions) have been installed on fire equipment, police cars, heavy trucks and private vehicles. Edit - 7/7/2010 - I've recently discovered - as of February 1951 Unity was advertising "over five million Unity lights in use" as shown on the attached back up light box label.  Many spotlights were forced on new car buyers right after World War II. New vehicles were in short supply and high demand through the end of the 1940’s. Long waiting lists meant customers would buy whatever they could get. In this climate, dealers loaded new cars with high margin accessories (including spotlights), somewhat explaining why so many cars from the late 1940’s had spotlights in the first place. The overall Unity spotlight design remained relatively unchanged until the 1970’s, when the screw on lamp ornament or emblem was eliminated, and the one piece handle wedge was replaced with a tubular wedge and screw. There have been a variety of lamp head styles, most recently made of plastic. Many components are backward and forward compatible between eras, although my focus is specifically on the early S6 (six inch) round head model with the screw on emblem and one piece wedge bolt. Having spent most of my life in vehicles equipped with Unity spotlights, I recently decided to add a pair to my 1960 GMC. Common problems with old Unity spotlights (besides surface rust) include damaged parking/travel limiting interface, one or more gears may have broken teeth, defective switch, feed wire cut or damaged, and the plastic grip may be broken or not the desired color. When recently faced with rebuilding several more spotlights, I was disappointed to find virtually no information available on how to disassemble these lamps without risking at least cosmetic damage. Since one of my recent spotlight purchases was only good for parts, I tested all the practices on that one first. The lamps shown in the following photos all have the special short GM handle/grip. Other than length, it is essentially the same as any standard length black or ivory plastic handle/grip. The Unity S6 spotlight consists of 4 major components, labeled in the photo below: 1. Lamp head assembly. 2. Headpost housing assembly. 3. Tube and rod assembly. 4. Handle assembly. Also of note in this photo are the labeled screws and wedge bolt:  Although it doesn’t show up well, the next photo shows the location of the screw to adjust rotation tension on the lamp head:  The next picture shows the major components separated. To achieve this level of disassembly, the following steps apply: 1. Loosen the 3/8” nut from the wedge bolt. Align nut with end of wedge bolt threads. 2. Brace the opposite side of the handle with your free hand, and tap the wedge bolt free with a plastic hammer. Remove the nut and wedge bolt. 3. Handle is now free to slide off shaft. 4. Loosen the headpost housing clamping screw. 5. With a twisting motion pull the outer tube free of the headpost housing and remove from the inner tube. 6. Remove the emblem and bezel screws. Gently but firmly pull the bottom of the bezel away from the lamp shell, until the bulb/bezel assembly detaches. 7. Disconnect ground wire from bulb terminal, and power wire from probe in headpost. 8. Remove 9/16” nut and star washer holding shell to headpost. 9. Gently pull the lamp shell from the headpost until detached. 10. Remove the headpost assembly from the headpost housing by driving the solid tapered retaining pin out (this is not a roll pin). On all three of my lamps, the pin was originally installed from the passenger side of the head. This may have been standard practice, or coincidental. Perform close inspection to insure pin is extracted and inserted from the same side it was originally installed, to avoid damage to the casting. 11. The headpost assembly is a friction fit in the headpost housing. The easiest way to remove it is to temporarily reinstall the lamp shell, and using the shell as a lever pull the headpost free. Use caution handling the headpost assembly, there are small o-rings and a small spring surrounding the center pin, and a thin shim washer between the spring and the base of the gear section. 12. To remove the end plug from the headpost housing, remove the retaining screw under the bottom and tap the plug out from the inside through the headpost hole. This will avoid damage to the chrome finish by attempting to pry if off from the outside. 13. The rod and gear assembly will slide forward out of the inner tube, or if exceptionally dry may require a push from the handle end. Normally, no additional disassembly is required. If however the inner tube is damaged, or you want to change the shaft length of the light, the inner tube must be removed from the head housing. 14. Remove the inner tube retaining screw from the bottom of the head housing. 15. In order to prevent damage to the chrome finish of the head housing, drill a ½” hole in a piece of scrap wood. If the chrome finish is like new do the same thing with a piece of leather or vinyl. 16. Open the jaws on a bench vice at least ½”, insert the inner tube through the leather and wood block and rest on top of the vice with the inner tube pointing down. 17. Insert an 11/32” transfer punch into the front of the head housing and tap the inner tube free from the housing. Note – Virtually all parts from the same era Unity spotlights interchange, however many items were hand drilled and tapped without benefit of jigs or positional tooling. Although tubes can easily be interchanged, the threaded screw mounting holes may or may not line up. Note – for cleaning the inside of the inner and outer tubes, a 38 caliber or 9mm bore brush and patches work well. Note – The flat wedge clamping surface on the inner tube dictates the mounted angle of the handle in relation to the lamp head (it is not adjustable). Some tubes have one flat which positions the handle in direct alignment with the head. Other tubes (as shown) have two flats, allowing the handle to be offset 30 degrees for matching left and right installations.  Further disassembly shows the 3 parts of the tube and rod assembly. It is also easy to see in this photo how electricity is transmitted from the power wire through the switch, to the contact on the end of the rod & gear assembly. On the forward end of the rod, a bearing surface rubs against the spring loaded brass contact pin contained in the headpost assembly. Inside the lamp housing, a wire slips over this post and the other end connects to the bulb terminal.  Next is a close up shot of the forward end of the inner tube. The retaining hole is on the bottom, and the slot on top aligns with a corresponding protrusion in the head housing, locking the housing and inner tube into a fixed relationship.  Two issues are visible in the next photo. The rotational travel of the shaft is limited by an interference fit between the cut away end of the outer tube, and a nub or projection inside the handle housing (shown in the next photo). If either is damaged, it will not be possible to limit the fore and aft travel of the lamp. In the parked position, the lamp head will likely rest on the vehicle body. The cut away end of the tube must have square crisp edges. As shown, this damaged tube will chew away at the parking nub in the handle housing until it fails. Also shown are the dual flats on this particular inner tube. The lower flat has been used extensively with a loose wedge bolt to the point of deforming the tube. It can be put back in service however, but adhering a 3/16”x1/2” piece of thin shim stock to the wedge bolt with instant glue. In my application a junk feeler gauge provided the shim stock.  This photo shows the damage caused by a bad outer tube. 60-80% of the parking nub has been chewed off. On another handle in my assortment, the projection is completely gone. Note – there are three main reasons for this damage. A. Rough treatment parking the lamp. B. Allowing the wedge bolt to remain loose. C. Having the lamp mounted on a door instead of a post or other fixed position. When mounted on a door, slamming the door jars the spotlight head, transmitting force through the inner tube to the handle, chipping away at the projection in the handle. Keeping the wedge bolt tight will help, but this type of installation is more prone to travel limit failure than a post mounting.  The last photo shows the layout of the handle components. To disassemble: 1. Remove the screw from the bottom of the grip, and lift the cap free. 2. Hold the grip with a rubber faced glove and remove the 9/16” nut with an impact wrench. Note - the star washer and nut actually serve as a lock nut, holding the clearance setting between the plastic grip and the bushing. To reinstall thread the plastic grip on until snug, then back off until desired clearance is obtained. Prevent the handle and pinion from moving while tightening the nut 3. The plastic upper grip is simply unscrewed from the threaded shaft once the nut is removed. Do not attempt to remove the grip by hammering or prying. If necessary to prevent rotation of the pinion, jam the gears with something hard enough to block the gears yet soft enough to prevent damage. 4. To remove the bushing from the handle housing, attach a small gear clamp to the sleeve portion normally hidden by the grip. Tap the gear clamp lightly with a small hammer and the bushing should unscrew easily. 5. The pinion gear/shaft is a slip fit in the bushing. There is a cylindrical felt washer on the end that goes into the bushing, resting above the top of the grip. 6. Remove the switch cap screws (one on either side of the cap). 7. Remove the wire clamp from the passenger side of the handle. 8. Remove the switch retaining screw, extract the switch and wire from the handle housing. 9. Use caution - the driven gear in the handle is a slip fit in the housing and will fall free once the switch and pinion gear are removed. The gear is keyed to the slot in the end of the rod and gear assembly, and must be lined up when reinstalling the handle to seat correctly.  If you’ve gotten this far, putting it all back together isn’t that difficult by simply reversing the order. Other notes or points of interest – o Most damaged parts can be replaced with an order direct to Unityusa. Almost everything is available, except for some obsolete mounting brackets. Used spotlights with cosmetic problems can also be an inexpensive source for spare parts. o Most of the chrome components are made of brass or zinc and are easily damaged when using metal tools. o Some small dents in the shell can actually be worked out with thumb pressure or cautious and tedious picking with a padded tool from the inside. The shell is pressed brass and relatively soft. o Old grease can dry out enough to produce brittle chunks hard enough to break gear teeth in the handle or head housing. Avoid “testing” rotation of the lamp until you can pull it apart and remove the dead lubricant. o I have found white grease to work effectively in lubricating all internal parts, and I use it generously on the gears and inside the tubes. o Early bulb retainers had a full metal ring around the light bulb held in place with elongated C clips. This early retaining ring is one of the few parts made of carbon steel and can disintegrate completely if allowed to rust. Later versions hold the bulb in place with four simple W shaped springs. This method of bulb retention is preferred. o Customized cars almost never used Unity spotlights. Appleton spots have always been the standard for customs. Now if they would only bring back Spotty during intermission at the local drive in. Of course before that does any good someone will have to bring back the local drive in theater! And for those interested in mounting a Unity spotlight on a 60-63 Chevy or GMC truck, here's a link detailing the installation process: http://67-72chevytrucks.com/vboard/s...ight=spotlight Edit - and here are the vehicle code links for California and Washington state, pertaining to owning and using vehicle mounted spotlights: California: http://www.dmv.ca.gov/pubs/vctop/d12/vc24404.htm Washington: http://apps.leg.wa.gov/RCW/default.aspx?cite=46.37.180

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 Last edited by markeb01; 05-08-2012 at 01:01 AM. |

|

|

|

|

|

#2 |

|

Check The Champ, Demonstrator

Join Date: Jun 2009

Location: Montreal,Quebec

Posts: 6,625

|

Re: Unity Spotlight Repairs

Perhaps you should add a link to your spotlight installation thread!

__________________

1963 Chevrolet Truck Literature LINK: https://picasaweb.google.com/113840717762774560215 YouTube Channel with 20+ Original Chevrolet Truck Salesmen, Mechanics & Service Department Training Slideshows. https://www.youtube.com/results?sear...otruk63&page=1 |

|

|

|

|

|

#3 |

|

1961 crewcab

Join Date: Dec 2007

Location: missoula, mt

Posts: 6,164

|

Re: Unity Spotlight Repairs

great stuff this will help if I want to get my light working again..

adding install info to this thread would be great too!

__________________

60 build: http://67-72chevytrucks.com/vboard/s...d.php?t=280904 61 crew build: http://67-72chevytrucks.com/vboard/s...d.php?t=646830 63 build: http://67-72chevytrucks.com/vboard/s...d.php?t=336537 64 'burb build: http://67-72chevytrucks.com/vboard/s...d.php?t=448681 65 'burb build: http://67-72chevytrucks.com/vboard/s...d.php?t=590715 65 build: http://67-72chevytrucks.com/vboard/s...d.php?t=281955 |

|

|

|

|

|

#4 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

Thanks for the suggestion guys, I've added the link.

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Nov 2007

Location: New Blaine, Arkansas

Posts: 751

|

Re: Unity Spotlight Repairs

This is great.

Thanks, Tim |

|

|

|

|

|

#6 |

|

Account Suspended

Join Date: May 2005

Location: Kansas City, KS

Posts: 3,906

|

Re: Unity Spotlight Repairs

A lot of time and even more knowledge...thanks for sharing. I don't own a factory Unity spot, but this makes me want to go find one. Thanks for the impeecable write-up and your time to do so.

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2008

Location: Lacombe, LA

Posts: 2,768

|

Re: Unity Spotlight Repairs

Mark,

Thanks a Ton! It's people like you who make the hobby not as frustrating and fun!

__________________

http://s1299.photobucket.com/user/jb...23904108567829 |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Nov 2008

Location: Lacombe, LA

Posts: 2,768

|

Re: Unity Spotlight Repairs

I took a real hard look at mine and the only repairs I need is to a frayed wite for the on/off switch. Whel I am goin gto do is simply slip some rubberized heatsink over spot and try that. I don't want to go messign with anything inside, Although I did take it apart so that I can slip the mounting brakets off and make the ness. marks on the cab today.

Mark I'll send you a PM on something. Jake

__________________

http://s1299.photobucket.com/user/jb...23904108567829 |

|

|

|

|

|

#9 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

Hi Jake, email response sent.

You'll probably be happier in the end if you just replace the switch/wire assembly. It's very simple to do, just remove the two screws from the wire clamp on the side, the two screws from the switch cap, and the switch retaining screw above the switch. Then just pull the wire and switch and reverse the order. Unity still offers the switch & wire: http://unityusa.com/detail.aspx?ID=1168 And I think some of their dealers sell it even cheaper.

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Nov 2008

Location: Lacombe, LA

Posts: 2,768

|

Re: Unity Spotlight Repairs

O.K. Will Do on the oder of a new switch. Thanks for the parts link.

Jake

__________________

http://s1299.photobucket.com/user/jb...23904108567829 |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Nov 2008

Location: Houston TX

Posts: 362

|

Re: Unity Spotlight Repairs

wow, love the attention to details......great write up.

__________________

The price of cool aint cheap. |

|

|

|

|

|

#12 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

Update – Early to Late Interchange Information –

Having recently purchased a vintage spotlight which turned out to be cosmetically disappointing, I decided to buy an inexpensive ($25) NOS model from the 80’s  and attempt to swap out the bad parts. I can now confirm later model components from a 1970’s - 1980’s(?) Unity spotlight will directly replace similar items on the 1940’s – 1960’s versions. The end result will have two basic cosmetic differences from a vintage original. 1. The new handle no longer has the clamp and screws holding the wire where it exits the handle. This can be concealed by installing the handle on the driver side, so the wire is facing the floor.  2. The newer lamp shell no longer has the manufacturer and model information stamped into the shell surrounding the crest (because the crest has also been deleted). For comparison, this is an older shell with the ornament removed, attached to a later rim.  And here is the new shell, after drilling a new hole and mounting the crest. Although not original in appearance, it certainly is cleaner looking than the vintage version.  A. The following parts were kept from the vintage spotlight: Original tube & rod assembly (needed for correct length) Sealed beam spotlight bulb and rim (since it matches the other vintage bulb and rim) GM crest/ornament External slot head screws Special short GM grip assembly Handle wedge bolt B. The new lamp donated the: Lamp shell Headpost housing assembly Outer tube Handle assembly C. New parts not used: Halogen bulb Standard long plastic grip New design wedge and screw External Phillips-head screws (although easier to use, they take away from the vintage appearance). Following the procedures outlined earlier in the thread, both lamps were disassembled. As shown in the photo above, the original outer tube was damaged at the handle end, so the outer tube from the new lamp was shortened to the correct length with an automotive tubing cutter. Combined with the new handle the lamp now parks correctly. The new spotlight was assembled from the parts listed and installed without incident. Although the later rim was in mint condition, it wasn’t used because of a manufacturing defect in many of these newer rims. There is a tooling mark around the circumference of the rim about ¼” away from the glass. Older rims do not have this defect.  There are two versions of late style handle wedge. One has an angled flat to match the corresponding flat on the inner tube. The vintage wedge bolt fits in the same application and can be retained for a more vintage appearance. The other new style wedge has a curved surface for use on lamps where no flat is present on the inner tube.  Other points of general interest: 1. The early grip bushing is made of brass, or is brass plated, and shows as a brightly colored ring just above the handle grip. On later spotlights the bushing appears to be aluminum or pot metal, providing a dull lifeless appearance.  2. For anyone preferring the special short GM handle, not only is the handle grip unique, but so is the pinion. It might be possible to shorten the longer pinion, by threading more of the unthreaded shank and trimming the longer threaded portion. It is soft brass so it wouldn’t take much effort to modify. To reinstall the grip to the handle assembly, insert the pinion into the bushing, and thread the bushing into the handle housing while taking care not to pinch the gears together. Attach a small gear clamp to the portion of the bushing normally hidden by the grip. Tap the bushing tight, and remove the clamp. Insert the felt washer over the pinion and thread the grip onto the pinion until it stops against the bushing. Back off ¼ turn, hold the grip with a gloved hand and snug the nut up tight with an impact wrench. This will provide the proper clearance between the handle grip and the bushing. 3. Early head housings were apparently hand fitted as one piece with the forward end plug. The plug and housing appears as one piece with a very fine parting line. Later housings and plugs appear to be manufactured separately, and fit together poorly as shown in the next pic. My early head housing had bad chrome, so I needed to use the new version to achieve a uniform shiny finish:  4. My NOS 1980’s spotlight had a manufacturing defect in the handle housing. The inner hole must be 11/32” I.D. and mine was undersize about .002, which was just enough to prevent the handle from seating correctly. I simply bored it out to 11/32” by hand after which it installed perfectly. There always seem to be a generous supply of these NOS spotlights available on eBay at favorable pricing. Adding the earlier crest to the newer design can provide a lamp in excellent condition at far less expense than a vintage original. It also eliminates the risk of spending a small fortune on something that is suppose to look perfect, and doesn't.

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#13 |

|

Registered User

Join Date: May 2010

Location: San Jose, CA

Posts: 7

|

Re: Unity Spotlight Repairs

Great pics & instructions. Does any happen to have the Unity Spotlight mounting template for 64-66 Chevy trucks?

|

|

|

|

|

|

#14 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

You might want to take a look at this thread, it might provide what you need:

http://67-72chevytrucks.com/vboard/s...light+template |

|

|

|

|

|

#15 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

|

|

|

|

|

|

#16 |

|

Who Me?

Join Date: Sep 2010

Location: Royal Palm Beach, FL

Posts: 4,065

|

Re: Unity Spotlight Repairs

Nice write up. I had one on my 94 Caprice and it was frozen up. It was a pain to work on. This would have been handy to have at the time.

__________________

Steve Steve1997 Tahoe LT 4D 2WD (DD) 1961 Apache 10 (sold) 1965 C10 Stepper (sold) |

|

|

|

|

|

#17 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

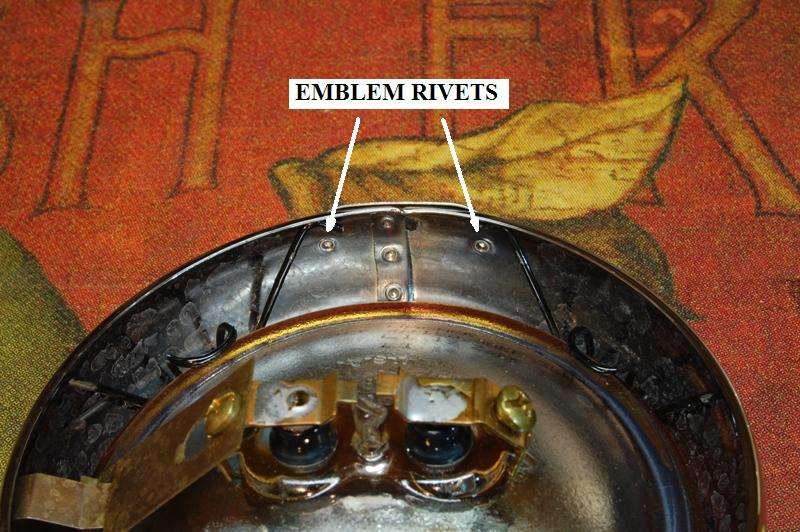

EDIT 01/07/2011 - Unity Fog Lamp Retrograde Update

If you are reading this post you may also have an interest in Unity Fog Lamps. Here is a somewhat simple process to modify 1970’s-1990’s lamps to look like earlier models from the 1940’s-1950’s. It involves removing the cheap looking flat Unity emblem and replacing it with the earlier raised design. This is what the later design looks like. A cheap looking shield that covers the seam in the rim:  And here is what the early raised emblem looks like by comparison:  The base part number for the fog light emblem is 4595-xx. In this case the part number is 4595-GM. 4595-U is the version that spells out UNITY instead of GM. There are quite a few other brand names available as well. Although similar in design, this is not the same part that fits on the spotlight heads. Those are larger with a different profile and are listed under part number 6295-xx. Unityusa.com offers these on their website, or you can purchase them from Accessoryland.com. Although the new emblem can simply be installed over the flat version, under close inspection it can be seen under the raised emblem, so I decided to remove them. Here’s what it takes: 1. Remove the rim/bulb assembly.  2. Wearing face protection, carefully remove the bulb retaining springs and the bulb from the rim. 3. From inside the rim, gently drill the lip off the rivets. 4. From inside the rim, drive the rivets out through the front. I used a spring loaded center punch. One snap per rivet and they popped out cleanly.  5. Close the rivet holes in the rim with a dab of your preferred sealant. I used masking tape on the outside to keep the sealant from dripping through the front.  6. Reassemble the rim/bulb assembly. Maintaining bulb alignment in the rim is made easier by aligning the bulb with the screw hole in the bottom, then stretching a piece of masking tape across the face to hold it in position while the retaining springs are installed. 7. Reinstall the rim/bulb assembly onto the lamp housing. 8. Carefully locate and align the emblem on top of the fog lamp, and fix it in position with masking tape. Triple check everything, then mark, drill and attach the new emblem. On my lamps the screws did not want to pull the emblem down tight enough to prevent movement, so I backed the screw out most of its length and placed a large speed nut inside on the screw. This speed nut provided plenty of grip to tighten the emblems snugly in position. The end result is a much richer, more authentic, and vintage looking lamp:

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: Feb 2011

Location: Ellensburg wa

Posts: 6

|

Re: Unity Spotlight Repairs

Anyone know where to find retainer wire clips that hold the bulb secure to the housing? Mine were completely rusted through

Posted via Mobile Device |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Nov 2010

Location: Fayetteville NC

Posts: 752

|

Re: Unity Spotlight Repairs

...just out of curiosity...how bright are these spotlights? I've always wondered about them but I've never had the opportunity to play with one in person.

|

|

|

|

|

|

#20 | ||

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

Just saw your questions today.

Quote:

http://shop.unityusa.com/U-6598-Spring_p_353.html They are also available at Accessoryland, but his website is currently offline. His phone number is listed as 563.556.5482 and 319.556.5482. Perhaps they had a recent area code split. If you order through Unity, talk to customer service and ask them to ship via a padded US Mail envelope. Otherwise the UPS cost will be as much as the parts. Quote:

As a frame of reference, a non-halogen high beam sealed beam head lamp bulb puts out 35,000 cp, while a halogen high beam bulb puts out 55,000 cp. Even the old sealed beam spotlight bulbs are more than twice as bright as an old sealed beam headlight on high beams, and the power just goes up from there. Beyond looking cool (if you like spotlights), they are very handy if you live in the country where there aren't any street lights, and can also be used as an under hood or work light when needed. Last edited by markeb01; 03-26-2011 at 02:19 AM. |

||

|

|

|

|

|

#21 |

|

Grandpa in the rustmobile...

Join Date: Nov 2008

Location: Spokane WA/Viola TN

Posts: 11,422

|

Re: Unity Spotlight Repairs

Bulb retaining clips are also now availible at napa. I called unity yesterday morning asking if they could make the shipping any cheaper. He gave me P/N 730-9520 I had to order them they come in today. $6 and change for 4 clips.

__________________

John Goose-1968 C10 355,9.32-1CR, Vortec Heads ,262 voodoo, 3.73:1 3OTT (HS ride/beater/farm truck) http://67-72chevytrucks.com/vboard/s...d.php?t=317684 Grams 53-1953 Chevrolet Belair http://67-72chevytrucks.com/vboard/s...=1#post4327784 1969 Chevy C10 Shortbed 4.5/6?" Frame off resto http://67-72chevytrucks.com/vboard/s...d.php?t=548136 1999 Toyota Tacoma 4x4 |

|

|

|

|

|

#22 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

Thanks to oldblue1968chevy and Unity, we now have a direct and less expensive source for bulb retaining clips. These frequently rust through and break allowing the bulb to flop around inside the rim/housing. Early Unity spotlights retained the bulb with a carbon steel circular ring, which also tended to rust away to complete deterioration. The replacement springs work in either application.

Through Unity, the clips are only $3.33 for a set of 4, but the shipping is $15.00. Here’s a photo of the springs, and link to the Unity offering:  http://shop.unityusa.com/U-6598-Spring_p_353.html Napa Auto Parts carries a compatible replacement part. Napa carries Balkamp part number BK 7309520. This is also a set of 4 springs. $6.09 at the Napa store with local pickup.  Thanks again to oldblue1968chevy for the tip and confirming the Napa springs fit perfectly! |

|

|

|

|

|

#23 |

|

Grandpa in the rustmobile...

Join Date: Nov 2008

Location: Spokane WA/Viola TN

Posts: 11,422

|

Re: Unity Spotlight Repairs

Your welcome

__________________

John Goose-1968 C10 355,9.32-1CR, Vortec Heads ,262 voodoo, 3.73:1 3OTT (HS ride/beater/farm truck) http://67-72chevytrucks.com/vboard/s...d.php?t=317684 Grams 53-1953 Chevrolet Belair http://67-72chevytrucks.com/vboard/s...=1#post4327784 1969 Chevy C10 Shortbed 4.5/6?" Frame off resto http://67-72chevytrucks.com/vboard/s...d.php?t=548136 1999 Toyota Tacoma 4x4 |

|

|

|

|

|

#24 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Unity Spotlight Repairs

Responding to requests for an internal wire routing diagram, following is a marked up photo explaining electrical flow from the power source to the bulb in a Unity spotlight:

1. Incoming voltage powers the switch through the wire entering the side of the handle housing. 2. When the switch is energized power is transferred through a spring loaded contact on the front of the switch into – 3. The handle end of the “rod”, in the rod and gear assembly. Power is transferred to the other end through the core of the rod - 4. And continues into the shell by another spring loaded contact riding on the bearing surface in front of the gear. This feeds through the headpost to a probe on top – 5 Which protrudes into the shell assembly. The wire that connects to the positive bulb terminal slips over the top of this probe after the lamp is assembled. The only actual wire anywhere in the spotlight is; A - into the switch, and B - out from probe #5 to the bulb itself. The lamp assembly is free to move in any direction since there is no internal wiring to bind on rotation. The ground side of the electrical circuit is handled by a wire riveted to the shell, which in turn grounds through the body mounting bracket(s). Smaller lamps like fog lights have a brass strip that connects the negative bulb terminal to the edge of the lamp shell. This brass ground connector can be seen in the 3rd photo in post #17 above (on the left side in the photo).

Last edited by markeb01; 10-16-2011 at 03:45 PM. |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Feb 2011

Location: Orient, Oregon

Posts: 722

|

Re: Unity Spotlight Repairs

Mark...

This is one of the best educational threads on the board... Thanks for informing us. I've got four or five complete assemblies in various states of condition. Now you've got me headed for the shed to check them out. The latest addition came off of a '64 service truck....and I think it's correct for the year.....I might be reconditioning it and puting it to use. One of the ones I've collected over the years is a "top" mount....also a fairly complete lamp. I'll snap a pic or two an post them for your comments when I get a minute.

__________________

Les Hunter '59 3803 someday to be 3853 '63 GMC K1000...351E, TH400 Daily '66 GMC 4000...351C, 5&2 |

|

|

|

|

| Bookmarks |

|

|