|

|

|

#226 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 21,907

|

Re: 1970 Med Olive Project

Quote:

I'm curious so I'll ask.... Is there a reason why you didn't run hard line for the bulk of the line & just the braided for the flex needed @ the ends? What's the service life expectancy? Would you share the costs? I ask because I sure want to do my 64 w/all flex line but many discouraged it. I felt if I set it up right, I could simply add it to a maintenance schedule for replacement @ certain intervals. Routing the hard line through all the boxing/bracing w/the PB components up front is a PITA (I did plumb it with 3/8" hard line already but I guess I should have put it in place before bolting all the front suspension pieces & brake lines into place). Really, really, would prefer to not have to disassemble all that & I might want to upgrade line size @ some point when the truck gets a new heartbeat.

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

#227 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

Scoti,

If we were talking about standard braided line, I would agree that you would need to service (replace) the line every few years because they will not hold up to pump gas and all of it's additives, especially in areas that use ethynol. I have always ran Pro-Lite 350 on all of my race cars and have gotten years of trouble free service running race gas. The cars we ran methanol in though, we would start seeing the lines start to soften after a couple of seasons. I will never run the pro-lite on anything that will see today's pump gas though. The BMRS lines use a PTFE liner that is impervious to all fuels and additives and will most likely outlast the car that your are puting them on as long as you keep them away from heat and keep any moving parts from rubbing. They are lighter and more flexible then the Pro-Lite 350 as well. Here is a link to what I am using. High Temp Polymer Braid. They have crimped fittings and BMRS pressure tests them to 250PSI. http://www.bmrs.net/PTFE_hose_01.html I will confirm when I get home but I'm pretty sure I have right at $275-$300 in all three lines and fittings for the cell. Yes it's a little pricey but like I said, they should outlast my truck. Anything I can use that gives me piece of mind and has little to no chance of failure, I will willingly spend a little extra $$ on. I will add that if you order these, ask for the swivel fittings so it's easier to clock your fittings at the pump, fuel rail etc..

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#228 | |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 21,907

|

Re: 1970 Med Olive Project

Quote:

I shall check into this. Thanks for the info & the link! (I only hope they have black anodized fittings)

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

|

#229 |

|

Registered User

Join Date: Mar 2013

Location: Newark, DE

Posts: 57

|

Re: 1970 Med Olive Project

Mike the fuel lines look awesome and I will be looking into them when I get there on my truck. Still waiting on that invite to come see it hahahaha����

__________________

Lorne Si vis pacem, para bellum 48 Ford F100 Panel 67 Chevy C10 71 Camaro RS 73 Camaro RS (in progress) |

|

|

|

|

|

#230 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

Nothing I plan ever seems to work out. I didn't manage to get anything done this week. I need to drop a bunch of little stuff and the core support off at powder coat Monday so today I finished up the mods on the core support and repaired the rusty area under the battery tray.

I ground all of the plug welds, once its blasted and powder coated the repair should disappear. I'm pretty happy I was able to save the original.

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#231 | |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

Quote:

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

|

#232 |

|

Senior Member

Join Date: Jun 2009

Location: Belews Creek , NC

Posts: 4,220

|

Re: 1970 Med Olive Project

Nice work on the support, and love the fuel lines I will be looking into those also

__________________

Larry It is easily overlooked that what is now called vintage was once brand new. "Project 68" paypal.me/ldgrant |

|

|

|

|

|

#233 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

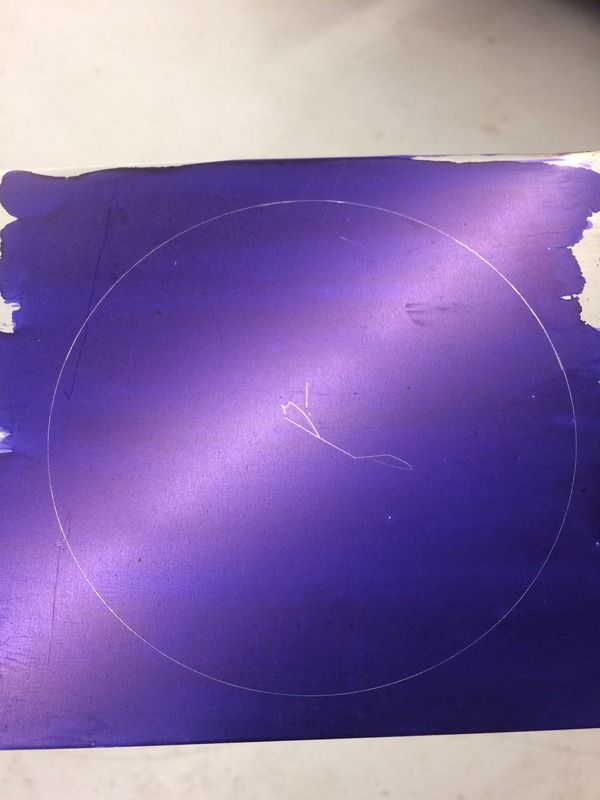

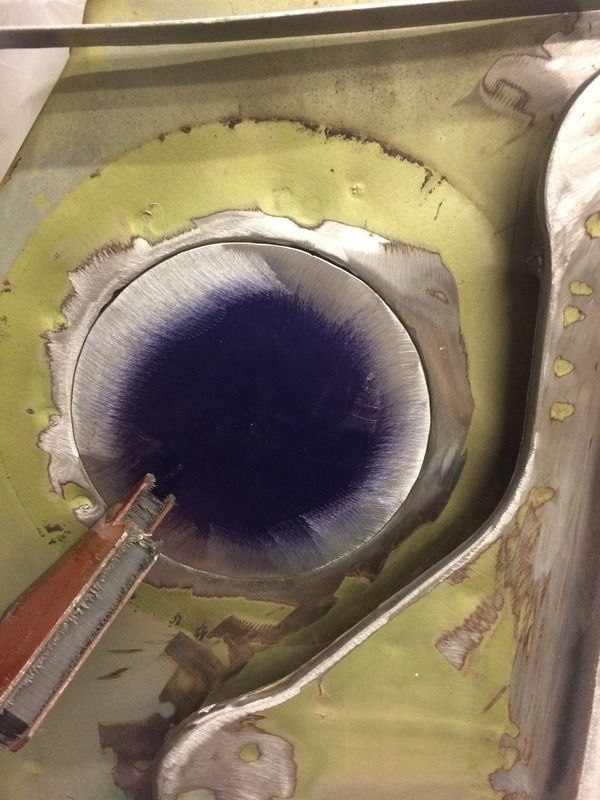

I knocked a little project out this morning on the truck. After moving the fuel tank out of the cab and not wanting to paint the truck, I wanted a simple way to fix the hole left by the factory tank filler neck. I found a universal filler neck and cut it down. I figured I should probably make a block off plate just in case someone other then me was driving and wasn't "thinking" and they stop for fuel.

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#234 |

|

Registered User

Join Date: Mar 2015

Location: Utah

Posts: 748

|

Re: 1970 Med Olive Project

I'm going to do the EXACT same thing on my truck! Where did you find the fuel filler?

__________________

72 GMC highlander nicknamed by my then 6-year-old brother "stripes" http://67-72chevytrucks.com/vboard/s....php?p=7378180 Check out my Youtube channel @Chad's Fab |

|

|

|

|

|

#235 |

|

Senior Member

Join Date: Jun 2009

Location: Belews Creek , NC

Posts: 4,220

|

Re: 1970 Med Olive Project

You could use it to hide a spare key

__________________

Larry It is easily overlooked that what is now called vintage was once brand new. "Project 68" paypal.me/ldgrant |

|

|

|

|

|

#236 |

|

Registered User

Join Date: Mar 2013

Location: Newark, DE

Posts: 57

|

Re: 1970 Med Olive Project

Nice job Mike.

__________________

Lorne Si vis pacem, para bellum 48 Ford F100 Panel 67 Chevy C10 71 Camaro RS 73 Camaro RS (in progress) |

|

|

|

|

|

#237 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

I got it off of eBay

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#238 |

|

Registered User

Join Date: Dec 2006

Location: Toms River, NJ

Posts: 5,518

|

Re: 1970 Med Olive Project

Awesome job Mike, I love that fuel filler!

__________________

Keith 66 Suburban Burb Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=751361 IG: bennett68c10 |

|

|

|

|

|

#239 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

I can't now, you just told everyone where to look

Thanks Lorne..Did you pull the trigger on that suspension yet? Thanks man..It was cheap and easy

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#240 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

I got back on the firewall last night and my boy came out with me. I made a filler panel to block off the blower motor hole and my son asked if he could do some welding. I got it positioned and tacked in and he finished welding it in and ground everything to get it ready for some body work. It's been a few months since he has had the mig gun in his hand but his welds had good fusion and looked ok. I'm super stoked he asked to come out and work with me because it hasn't happened in a while.

I also made a strip to start capping off the wire gutter. My boy started stitching it in on the drivers side. I really need to get that passenger corner finished Saturday so we can finish off the wire gutter.  If you can't tell I'm a proud daddy  And I know I'm going to catch hell for letting him weld in slides (flip flops) but that's all these kids wear year round. I'm getting old And I know I'm going to catch hell for letting him weld in slides (flip flops) but that's all these kids wear year round. I'm getting old

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 Last edited by MMcMasters; 03-30-2017 at 09:11 PM. |

|

|

|

|

|

#241 |

|

Senior Member

Join Date: Jan 2015

Location: Marquette Heights, IL.

Posts: 1,135

|

Re: 1970 Med Olive Project

I wish I could see your pics here at work...but I am sure there is a grin from ear to ear with your son by your side working. Glad to hear you two had a good time and got something done!

__________________

Jimmy Hoelzel |

|

|

|

|

|

#242 |

|

Senior Member

Join Date: Jun 2009

Location: Belews Creek , NC

Posts: 4,220

|

Re: 1970 Med Olive Project

Very cool to see the young man out and doing some welding for you

I was going to say I do not believe that is the best attire for welding I was going to say I do not believe that is the best attire for welding  One good hot piece of slag and he will change his mind on wearing those to the shop One good hot piece of slag and he will change his mind on wearing those to the shop  Sorry to give up your secret hiding spot

__________________

Larry It is easily overlooked that what is now called vintage was once brand new. "Project 68" paypal.me/ldgrant |

|

|

|

|

|

#243 |

|

Registered User

Join Date: Dec 2006

Location: Toms River, NJ

Posts: 5,518

|

Re: 1970 Med Olive Project

Hey Mike, I think your son did a pretty good job! Probably welds better than I do

__________________

Keith 66 Suburban Burb Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=751361 IG: bennett68c10 |

|

|

|

|

|

#244 |

|

Registered User

Join Date: Mar 2013

Location: Newark, DE

Posts: 57

|

Re: 1970 Med Olive Project

Mike,

Everything is turning out great with your truck!! I haven't pulled the trigger yet because I'm waiting to get the frame completely disassembled. I'm pulling the trigger today on those doors from AMD!

__________________

Lorne Si vis pacem, para bellum 48 Ford F100 Panel 67 Chevy C10 71 Camaro RS 73 Camaro RS (in progress) |

|

|

|

|

|

#245 | |||

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

Quote:

Quote:

Quote:

Please share how they fit..I still need a set for my boys truck

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|||

|

|

|

|

|

#246 |

|

Registered User

Join Date: Mar 2013

Location: Newark, DE

Posts: 57

|

Re: 1970 Med Olive Project

I will definitely let you know once they're in and worked.

__________________

Lorne Si vis pacem, para bellum 48 Ford F100 Panel 67 Chevy C10 71 Camaro RS 73 Camaro RS (in progress) |

|

|

|

|

|

#247 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

Dave from PB notified me that my corner firewall piece shipped this week so I'm going to wait on that and put the firewall project on hold. I decided to rebuild my factory A/C controller today since it has two broken levers and I will be installing the Vintage Air in the next week or so. I had ordered a rebuild kit already and it was still in the box on a shelf. I got my old unit disassembled and began putting it back together when I discovered the new rebuild kit does not have the spring washers included that hold the outer levers to the new replacement levers. This is my fault

I have had this kit in my possession for some time now and never opened it. I have had this kit in my possession for some time now and never opened it. I'm going to try to order the spring washers today but I was hoping that with the knowledge on this board, someone else had found similar spring washers at a local Lowes, Home Depot etc.. and could lead me in the right direction. If not, I will hurry up and wait on them to arrive.    and this is where I'm stopped at...so frustrating

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#248 | |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,827

|

Re: 1970 Med Olive Project

Quote:

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

|

#249 |

|

Registered User

Join Date: Dec 2012

Location: Rochester, IL

Posts: 537

|

Re: 1970 Med Olive Project

I called them spring washers but the technical name is a push nut.

__________________

__________________ Mike 70 Med Olive build http://67-72chevytrucks.com/vboard/s...d.php?t=714804 Instagram- protouring66 |

|

|

|

|

|

#250 | |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,827

|

Re: 1970 Med Olive Project

Quote:

I'm pretty sure new ones come with your Vintage Air kit.

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

| Bookmarks |

|

|