|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#51 | |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,666

|

Re: I Know SQUAT About Spraying Automotive Paint.

Quote:

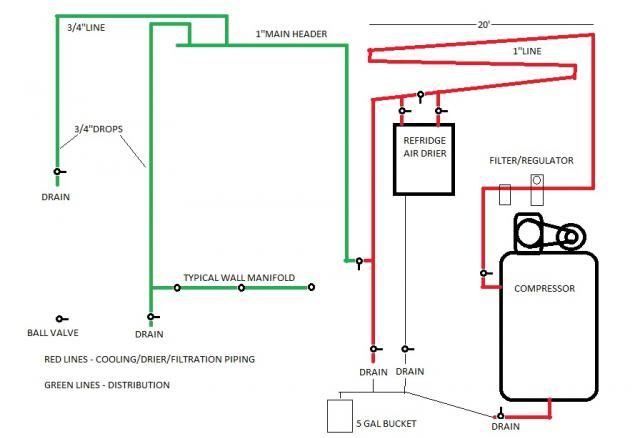

other than that it could be mounted anywhere you want as long as everything slopes to a drain on the drain, try to have a long leg under the cooler with a valve at the bottom the leg is your daily reservoir to catch water i run the coil copper above my compressor, air in on the top and gravity drain into the tank i don't run a cooling loop in my home shop, 30 feet of headers drain back to the tank it even drains back thru the regulator  the auto shop is a whole different animal... 5 to 8 shop employees all using air tools, paint booth, cnc plasma table and a 37 cfm compressor our 60 foot initial cooling loop goes up high on a block wall and gravity drains into a refrigerated dryer then back to the ceiling for distribution we do use a desiccant dryer at the paint booth too

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

|

#52 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,331

|

Re: I Know SQUAT About Spraying Automotive Paint.

Thanks ogre.

The rafters really might be an option for me. The long leg would be from up there down to the regulator/separator/hose reel. Probably 10 ft or so.

__________________

'55 Big Window Shortbed, Drive-It-&-Work-On-It slid down the "slippery slope" to a Frame-Off Rodstoration! LQ4/4l85e/C4 IFS/Mustang 8.8 rearend w/3.73's Dan's '55 Big Window "Build" - Well, Kinda! |

|

|

|

|

|

#53 |

|

Registered User

Join Date: Sep 2014

Location: Peachtree City Georgia

Posts: 26

|

Re: I Know SQUAT About Spraying Automotive Paint.

Everything I know about painting I learned online. No real hands on knowledge but I have the same theory as yourself, if I do it myself I know its done. Plus I like to say I did it myself when ever possible. So with that said go for it!

I'm sanding down my old Lincoln; doing body work, cutting rust and welding in sheet metal, pulling dents and applying epoxy on entire car to cover bare metal and old paint then putting on layers of urethane for block sanding. If you mess up the metal cut it out and do it again. As far as primer, well thats really easy to sand off of do again and the perfect time to get comfortable with your gun control and learn to spray. I can only advise what I know (which isn't much) but what I advise is read alot, ask questions and then take your time and go for it. So far I haven't had to cut anything back out and like others said most of your primer ends up on the floor from sanding anyways. I have a small garage so I have the same issue as you regarding space, heres what I did. I'm using this small 40 gal Husky compressor (I'm only two paychecks away from my new Quincy 60 gal.) The drop goes down to a ball valve to let the water out.  Then across the top of the garage door and down the other side and down to the hose reel. And yes I wrapped the copper with tape to keep the dissimilar metals from contacting.   I totally screwed up, I think it was from the Georgia heat when I first moved here messing with my brain. I had the parts to: A) make my hose drop like Ogre posted and a tee and ball valve to add another drop to catch water before the hose reel and some how totally forgot so I'll be redoing that. BUT I haven't got a single drop of water in my gun with this set up as is. Eventually I will add an inline oiler to this end for tools and run another line furher down the wall further from here   And at the end have another air/water trap with a hose reel just for painting, probably with a half inch hose for spraying. This allows me to save all my wall space in my small garage and still get the job done. Good Luck and sub'd to see the outcome. |

|

|

|

|

|

#54 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,331

|

Re: I Know SQUAT About Spraying Automotive Paint.

Thanks 66SS,

I like your setup. Where can I get those type of pipe clamps? My compressor will be in the front left corner of my very small 18x18 garage where that red dolly is now:  There not enough width for the compressor to fit with those wheels:  So I'll mount those in the back left corner where I have some structural steel I installed a couple years ago when I removed most of the rear wall so my boat would fit in the garage:  Pardon the total mess this photo shows. The walls have since been covered with OSB and painted white. That rear extension to the garage that the old owner added in the 60's has since been reconfigured. I think I'll mount the retractable hose reel above my head and the two mag wheels below on the steel as extra hose storage and for long extension cords. That'll give me 20 ft. plus of piping between the compressor and reel for cooling and condensation but I'll also get a water separator. I'll mount it on the wall or overhead like you did

__________________

'55 Big Window Shortbed, Drive-It-&-Work-On-It slid down the "slippery slope" to a Frame-Off Rodstoration! LQ4/4l85e/C4 IFS/Mustang 8.8 rearend w/3.73's Dan's '55 Big Window "Build" - Well, Kinda! Last edited by Dan in Pasadena; 07-11-2015 at 02:39 PM. |

|

|

|

|

|

#55 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,666

|

Re: I Know SQUAT About Spraying Automotive Paint.

the straps show are stand off straps for electrical conduit, aka mineral-x

i'd recommend these straps for copper pipe, they are cheap and made for copper

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#56 |

|

Registered User

Join Date: Sep 2014

Location: Peachtree City Georgia

Posts: 26

|

Re: I Know SQUAT About Spraying Automotive Paint.

Ogre is right, those clamps are made for copper and cheaper. You could do the same thing as me by hanging a piece of wood down instead of all-thread and using the copper clamps and save some money.

I got my clamps from Home Depot and they are made for holding conduit. They do make them in copper but you'd probably need to go to a plumbing supply house. Here's a link to what I was thinking of using. There are various types just Google copper pipe clamp. http://vegaindustrialsupply.com/yaho...075348_std.jpg I did wrap mine very well to keep the metal apart:  And spent a little more to use these hangers so I could really fine tune and adjust the slope of the pipe to keep the water running down hill and not have any dips in the line for water to collect in when air isn't flowing.  Once again in this photo you can see the string line I ran to get the slope I wanted. I still hadn't wrapped the pipe in this picture. I'm an amateur, not a plumber, so I slip fit all my stuff together and then took it apart, sweat on the tees and/or 90's then wrapped the tape where the hangers went. Then I hung it all back up and connected the pipes with my couplings, twisted the pipes so I could get the tees/90's the direction/slope I wanted them and sweated the couplings together. Certainly a lot of extra steps from how a pro would do it but it came out good the first try. Well other than me forgetting that extra tee and the drop with the ball valve at the end. But even without that stuff I was D/Aing on my car a bunch yesterday. And while my tank and separator had a some water in them from the compressor running the whole time I never got water at my tool. My "shop" is probably a little bigger but space is at a premium, especially when working on something as big as a 66 Lincoln.

|

|

|

|

|

|

#57 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,331

|

Re: I Know SQUAT About Spraying Automotive Paint.

Huh? Why would you wrap the copper? I thought the whole point f using copper is that it disappates heat faster than black iron or galvanized. Why would you WANT to insulate it with wrap?

PS: I like those Vega Industrial Supply copper hangers but they look pricey. Not sure why I'll do but I do know about the issue of dissimilar metals, galvanic action and also just the wear on two adjacent parts when they vibrate so I'll be careful.

__________________

'55 Big Window Shortbed, Drive-It-&-Work-On-It slid down the "slippery slope" to a Frame-Off Rodstoration! LQ4/4l85e/C4 IFS/Mustang 8.8 rearend w/3.73's Dan's '55 Big Window "Build" - Well, Kinda! |

|

|

|

|

|

#58 | |

|

Registered User

Join Date: Aug 2014

Location: Fort Dodge, Iowa

Posts: 120

|

Re: I Know SQUAT About Spraying Automotive Paint.

Quote:

|

|

|

|

|

|

|

#59 |

|

Senior Member

Join Date: Nov 2008

Location: Glendora, CA

Posts: 6,331

|

Re: I Know SQUAT About Spraying Automotive Paint.

Ah so.... I thought he meant he wrapped the entire pipe.

__________________

'55 Big Window Shortbed, Drive-It-&-Work-On-It slid down the "slippery slope" to a Frame-Off Rodstoration! LQ4/4l85e/C4 IFS/Mustang 8.8 rearend w/3.73's Dan's '55 Big Window "Build" - Well, Kinda! |

|

|

|

|

|

#60 |

|

Registered User

Join Date: Sep 2014

Location: Peachtree City Georgia

Posts: 26

|

Re: I Know SQUAT About Spraying Automotive Paint.

What Richs55 said is why.

|

|

|

|

|

| Bookmarks |

|

|