|

|

|

#976 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks for checking out the progress Jim!

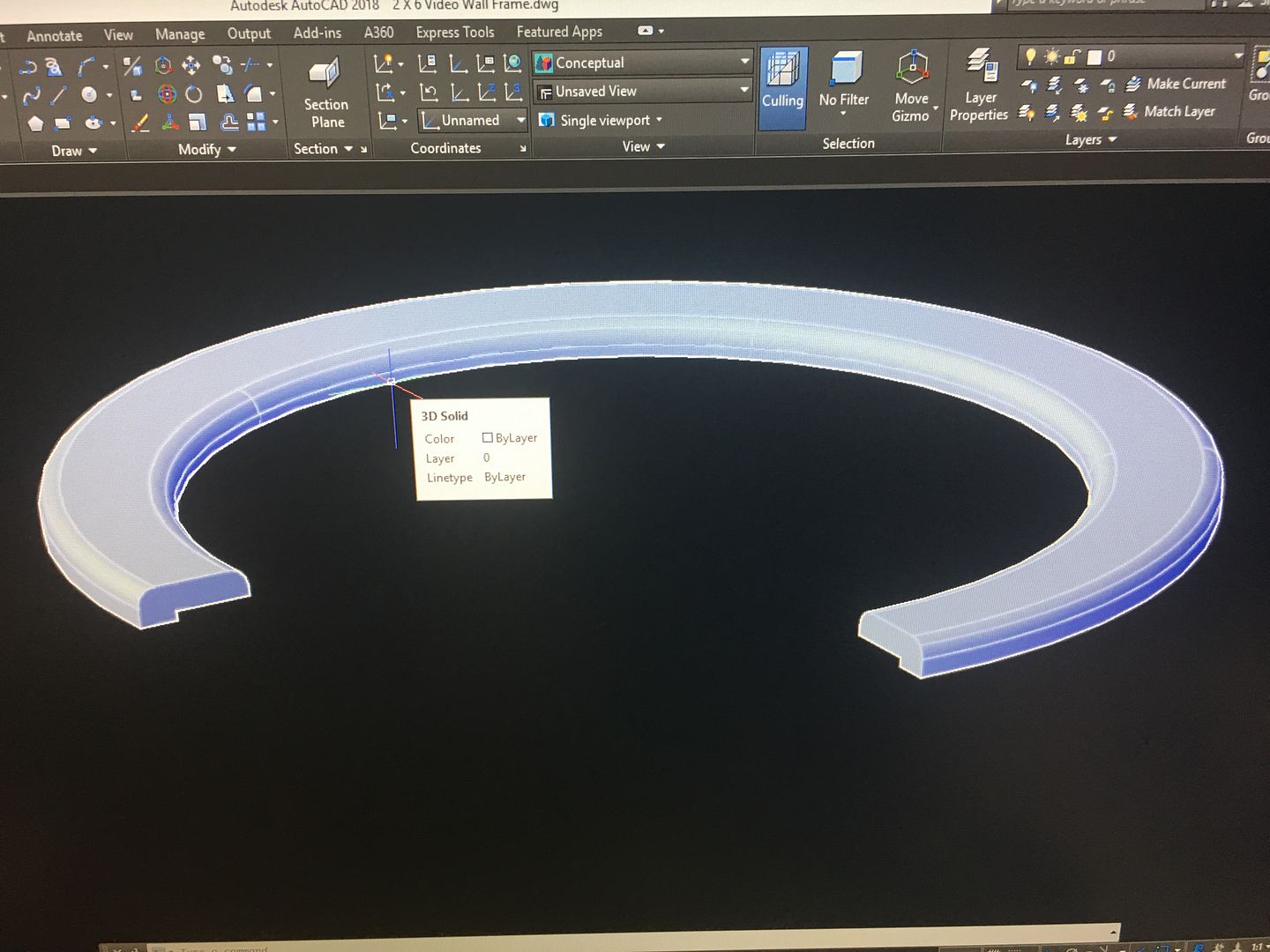

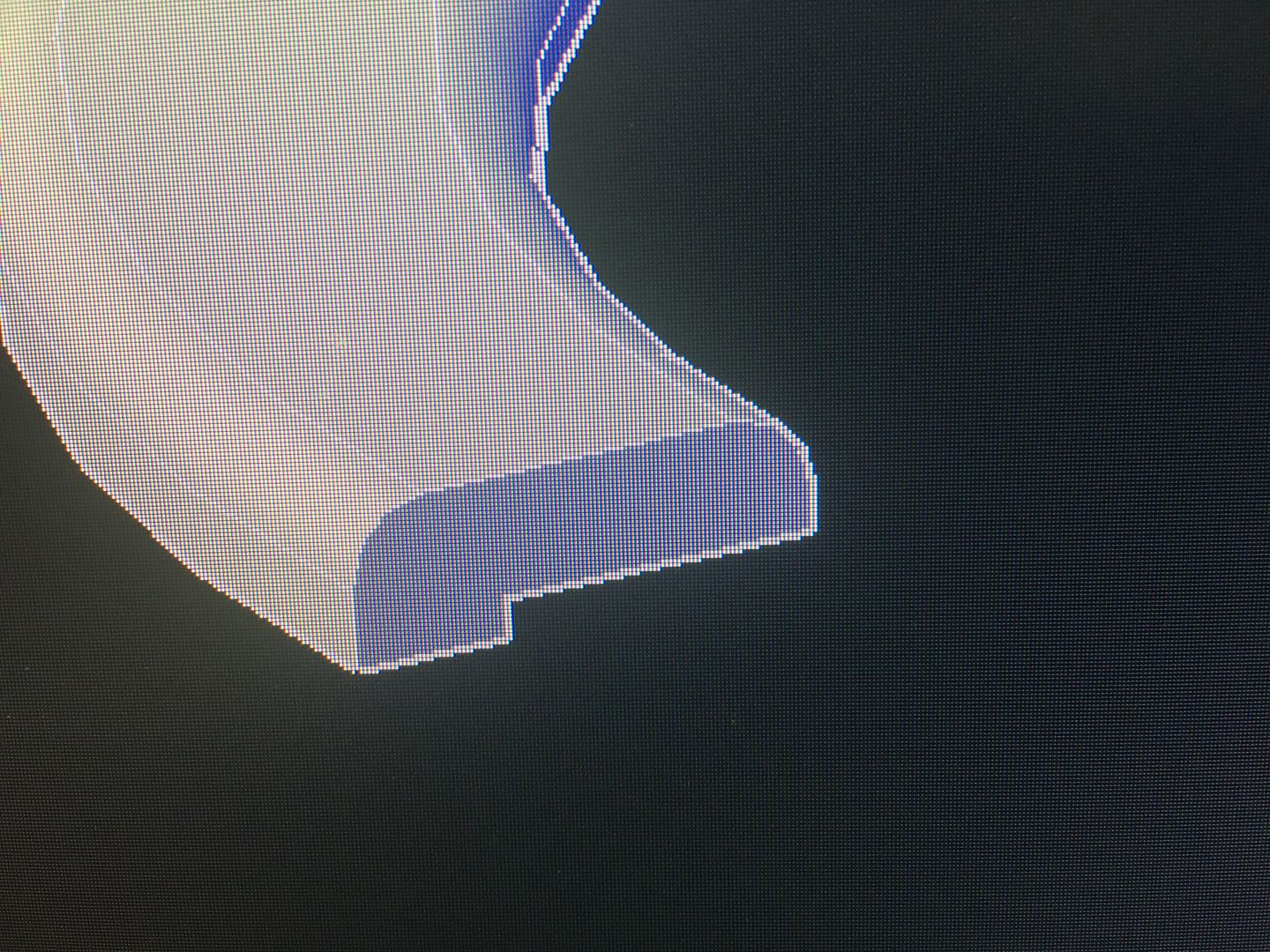

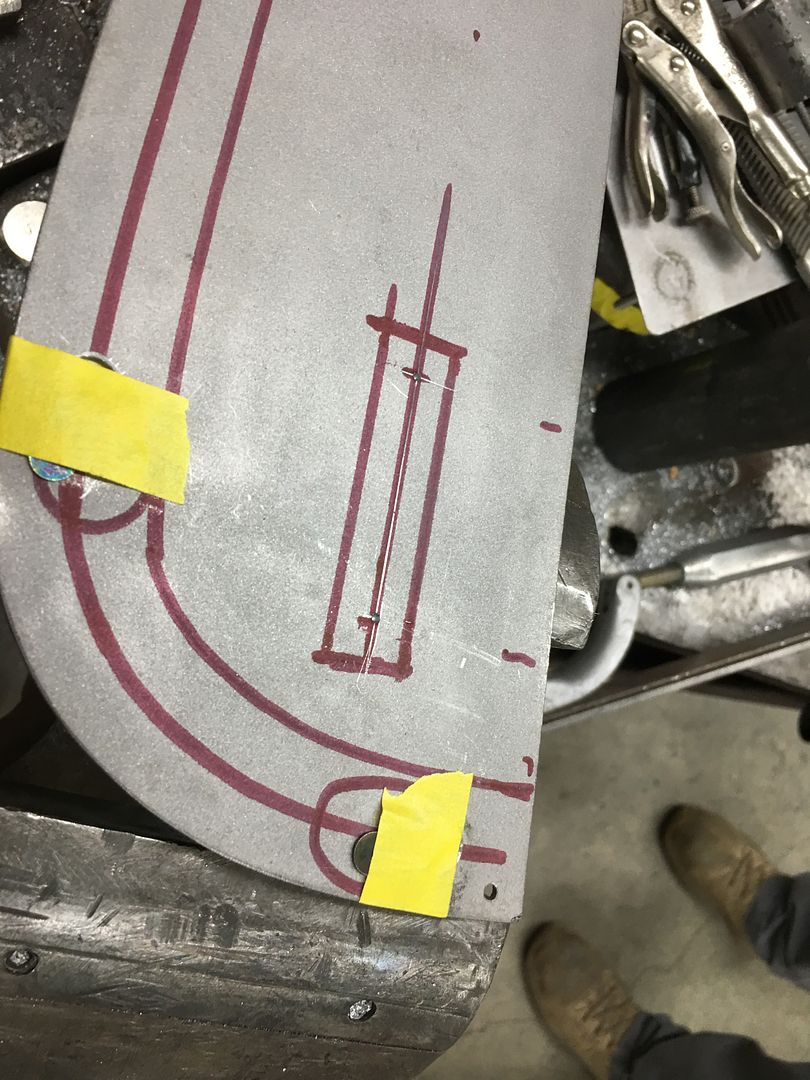

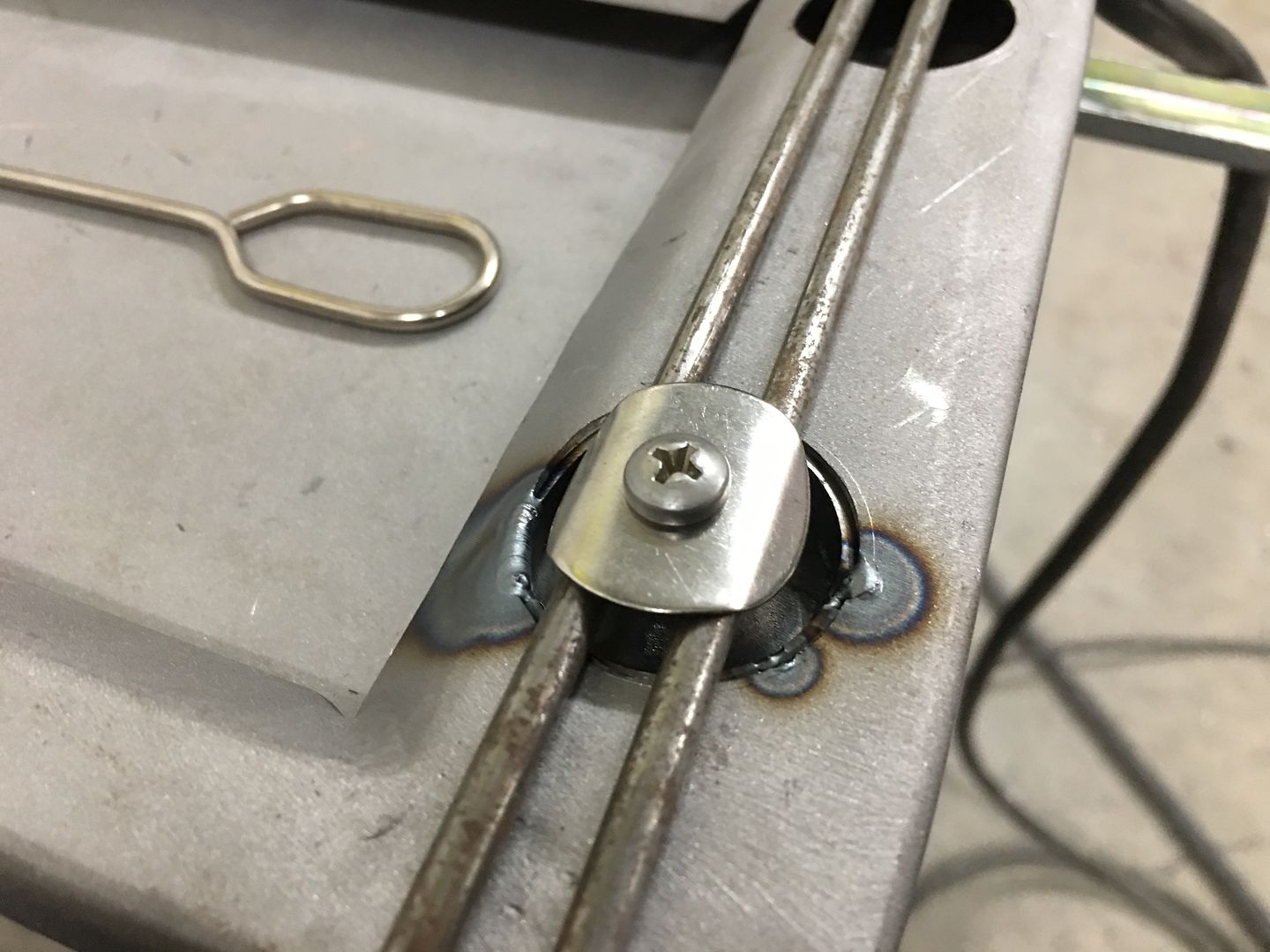

Today we were working on more interior parts for Gary to upholster. Here is the design for the trim rings for our speakers, the cutaway shows the relief on the bottom which provides clearance for stainless mesh. This should provide a more 55 correct grill for the speakers than the plastic ones it came with. My cousin JB is making the trim rings for us..   Mike trimmed out the slots we previously had for the bass speaker, it will also get the trim ring and mesh treatment.  We drilled holes in the rear kick panel arm rest for panel clips to hold the arm rest down. I thought these would be a better option than the wire clips..  We also needed an escutcheon for our seat belt to pass through the arm rest, as the retractor is located behind the kick panel. Not finding much in the local salvage yard but plastic to choose from, and little in aftermarket, we opted to make a sample out of steel to insure the seat belt buckle and harness support would pass through. We will make the final version out of stainless and polish them..   Cleaned up and "polished" with Scotchbrite rolocs to simulate what the stainless should look like..   In our arm rest two clearance holes are drilled, then a cut made between the two. Next, the two "tabs" are hammered downward to provide the void needed for the escutcheon such that they are tight enough to hold it in place.

__________________

Robert |

|

|

|

|

|

#977 |

|

Registered User

Join Date: Nov 2011

Location: West Plains Missouri

Posts: 2,088

|

Re: 55 Wagon Progress

Came out nice Robert.

Mark

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=645774 Project Orangepeel 52 A.D. http://67-72chevytrucks.com/vboard/s...d.php?t=653337 John's LS 49 dodge http://67-72chevytrucks.com/vboard/s...d.php?t=655780 Blake's 67 GMC LS stepside http://67-72chevytrucks.com/vboard/s...d.php?t=690527 Reed 78 FJ40 Rebuild http://67-72chevytrucks.com/vboard/s...d.php?t=733259 Barger's 78 FJ40 |

|

|

|

|

|

#978 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,553

|

Re: 55 Wagon Progress

Robert, I would be happy with the sample you made, nice work...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#979 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks for the comments guys!

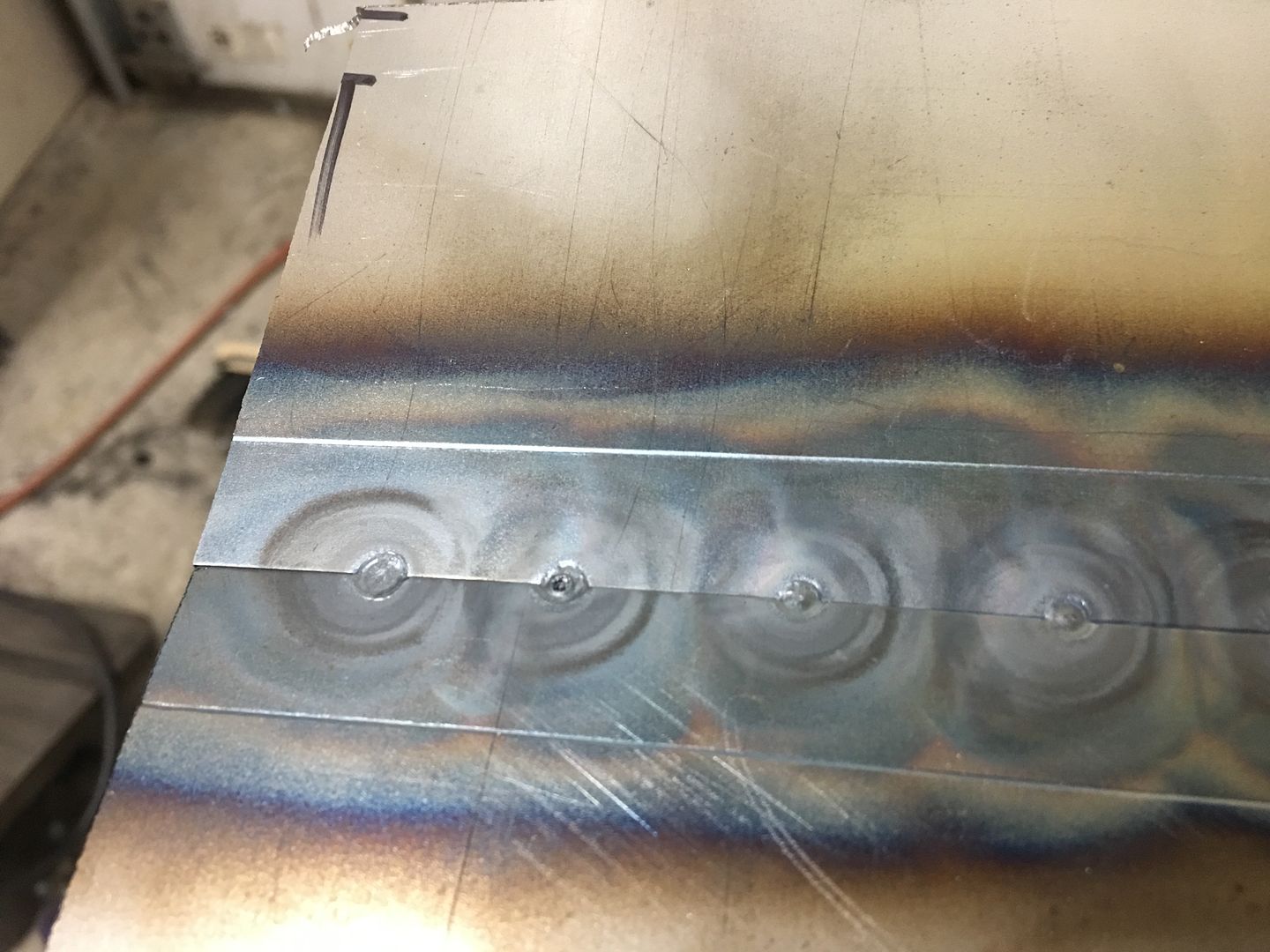

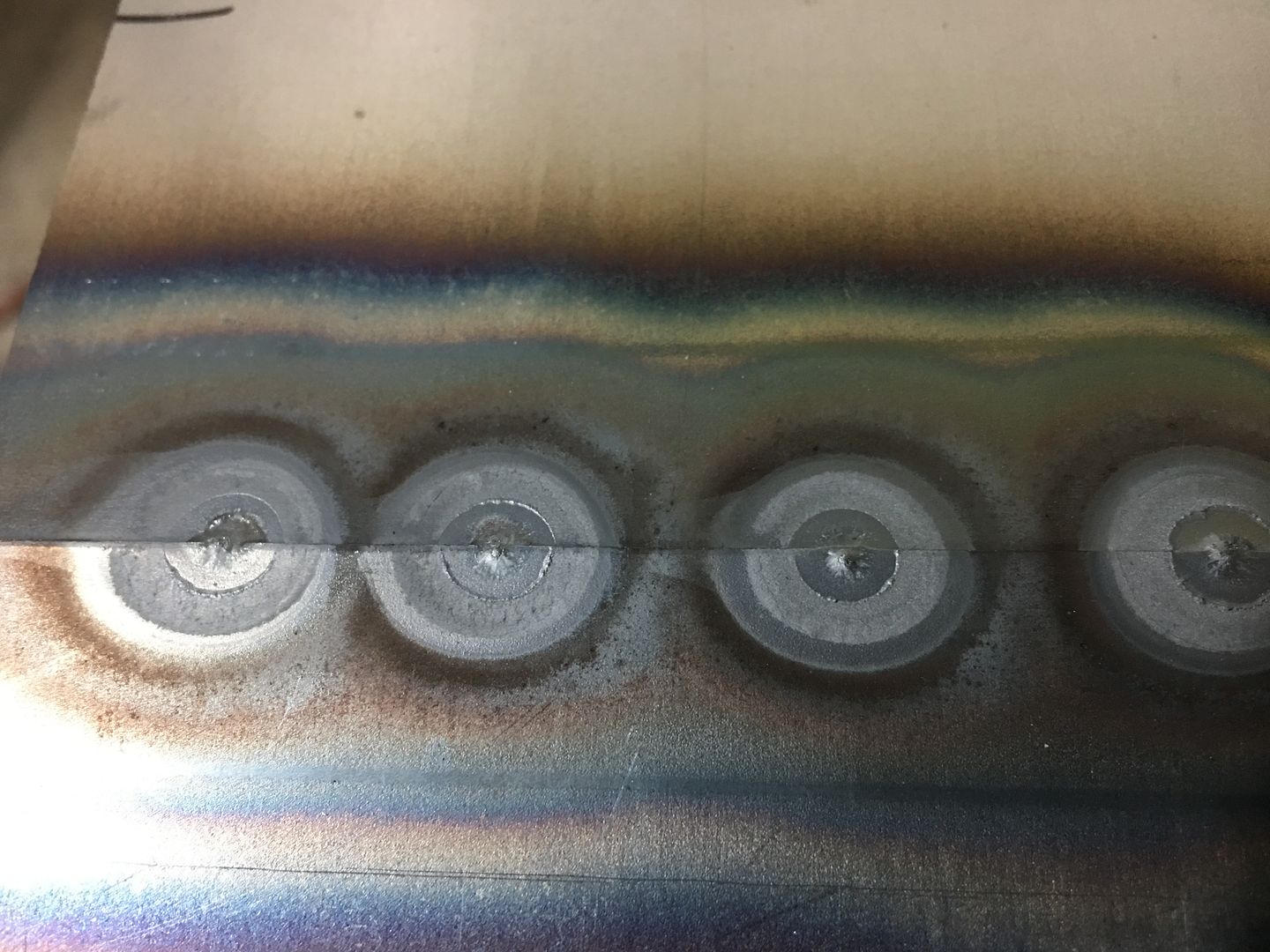

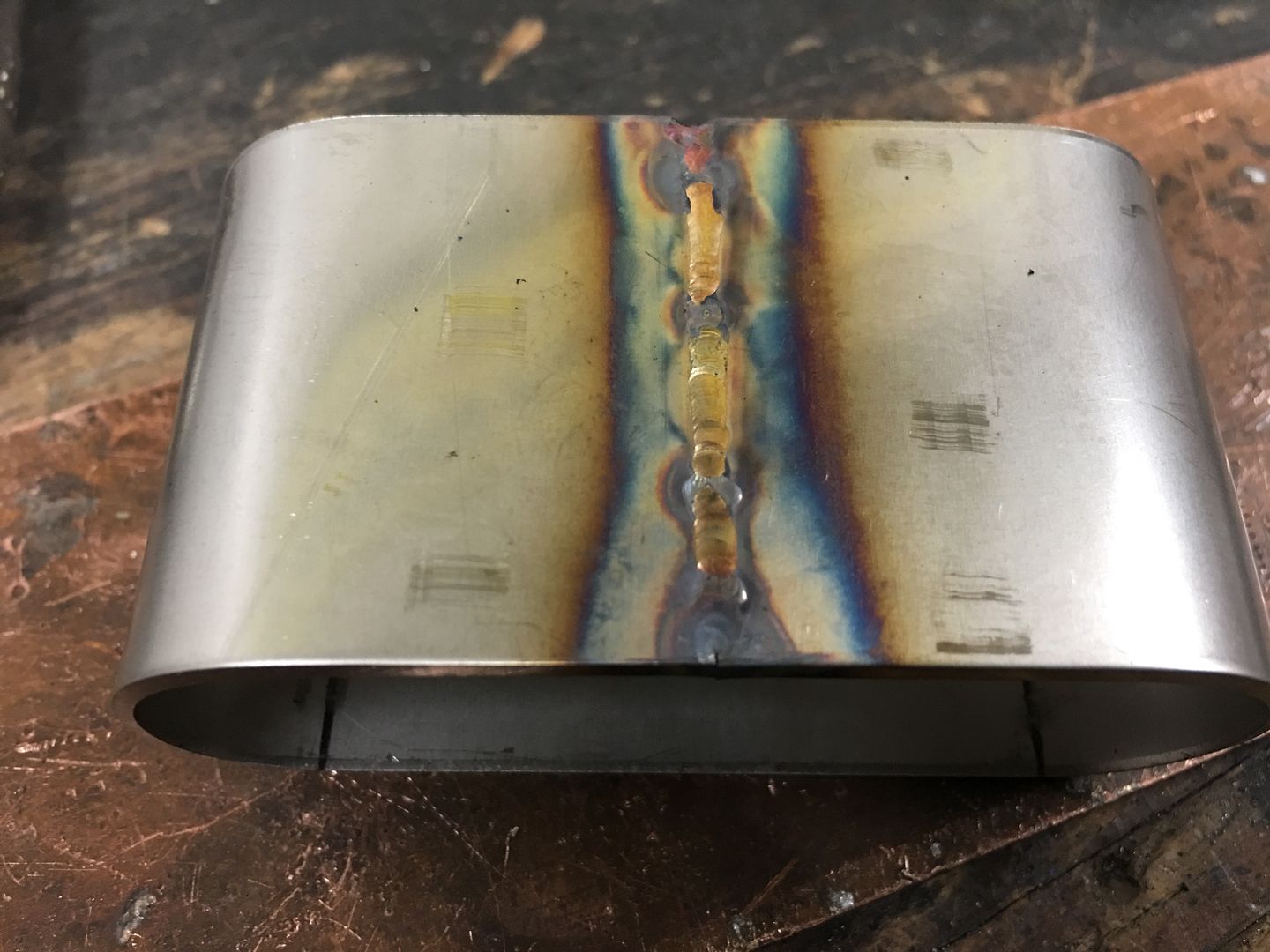

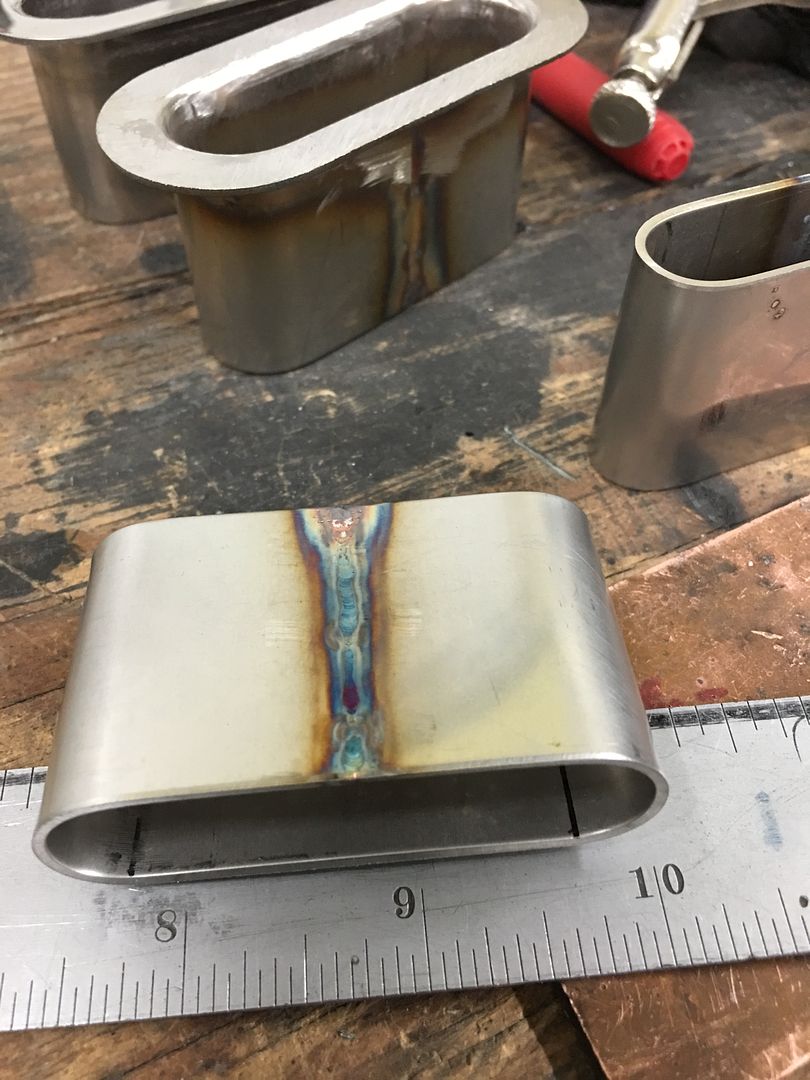

Got a new addition to the shop, this Meco came from TM Technologies, or TinManTech. I got it hooked up last night and ran a couple passes.  Let me start by saying I am not a gas welder. I have a Henrob torch that I have found awkward to use, likely the operator, so I have always used either MIG or TIG. This video shows my second attempt with the Meco, the first attempt I did not have sufficient heat as I was worried about blowing holes. The two “scraps” were picked off the floor and tacked together about every 3/4”, then fusion welded the distance shown, yielding a full penetration weld with nice HAZ conisistency. Very impressed with the light weight and ease of use, even for an old dog learning new tricks. Video shows in order: front, back, planished, and bent at 90* for our destruction test. https://www.youtube.com/watch?v=td4y...ature=youtu.be Tacks, front side..  Rear side, full penetration...  Full pass with full weld penetration, bent 90* for destruction test.. Line shown is mark left by press brake die....  Rear side held up well  Very impressed with this torch, one handed valve adjustments are a breeze, light weight and easy to use..

__________________

Robert |

|

|

|

|

|

#980 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,578

|

Re: 55 Wagon Progress

That's sweet Robert....been along time since I did fusion welding...that "tiny"torch looks to have done a good job.....

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#981 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks Greg!

I was asked to bend the weld sample to a complete 180* to give the weld a "REAL" test. So the following video does such, please excuse the erratic movement of the camera operator, he also had to close the vise and position the sample as well.. and then there's the drop test.... https://www.youtube.com/watch?v=JzfLxkMZbEk .

__________________

Robert |

|

|

|

|

|

#982 |

|

Registered User

Join Date: Nov 2013

Location: Antioch, Ca.

Posts: 442

|

Re: 55 Wagon Progress

Hey wait Robert you're here too? I read this thread on Tri-Five too!

__________________

Take Care Troy |

|

|

|

|

|

#983 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Best wishes to everyone for a healthy and prosperous New Year!

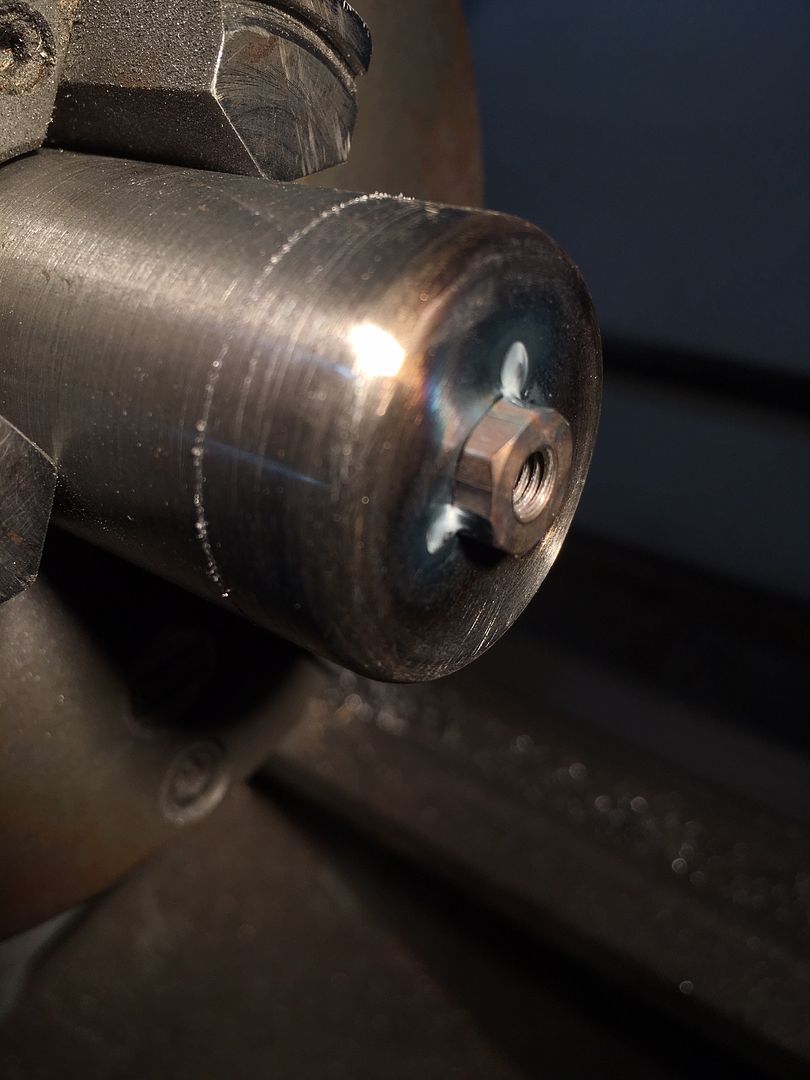

Some wagon updates, we've been tying up loose ends to get parts ready for upholstery and the roof ready for paint. With the arm rest details ironed out, E is unbolting the kick panels so we can cut out the speaker holes. Mike is getting the roof skin blocked out..   Here's the last detail for the console, we still need our latching mechanism. To keep a minimalist approach, we're going to flush recess some rare earth magnets in the lid, so here's our "pockets" that will be welded into the lid. Starting with some .065 wall tubing the end was faced on the lathe, and the end plates turned to a welding diameter of slightly undersized than the tubing, which allows for a good fusion weld.  Tacked:  Fusion welded using the TIG:  10-32 hex nut for magnet attachment is tacked on....  Trimmed to size...  The material scraps shown were to simulate what will be covering the console and lid for the "pull test". Three magnets appeared to work too well, so we are going drill holes and weld in our recess pockets to use two magnets but leave a space in the center for a third, just in case... Once welded and fitted we'll do one more pull test just to make sure the third one isn't needed..  We also had some parts water jetted out of stainless for our seat belt escutcheons, this should help us get better consistency between parts.....and save time..

__________________

Robert Last edited by MP&C; 01-02-2019 at 03:45 PM. |

|

|

|

|

|

#984 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,578

|

Re: 55 Wagon Progress

nice work...waterjet does make it nice...

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#985 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,553

|

Re: 55 Wagon Progress

Robert, nice work as always...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#986 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks guys!

We got the holes added in the console lid for the pocket recesses.....  A bent fender washer and 3/16 rods serve to hold the pockets in place while tacked in with the TIG....   Test fit of the magnets...   Video of the console lid, testing the magnet pull for our latching method.. https://www.youtube.com/watch?v=vgJM...ature=youtu.be .

__________________

Robert |

|

|

|

|

|

#987 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,578

|

Re: 55 Wagon Progress

That works great!! Nice work..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#988 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,553

|

Re: 55 Wagon Progress

Very nice...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#989 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks guys!!

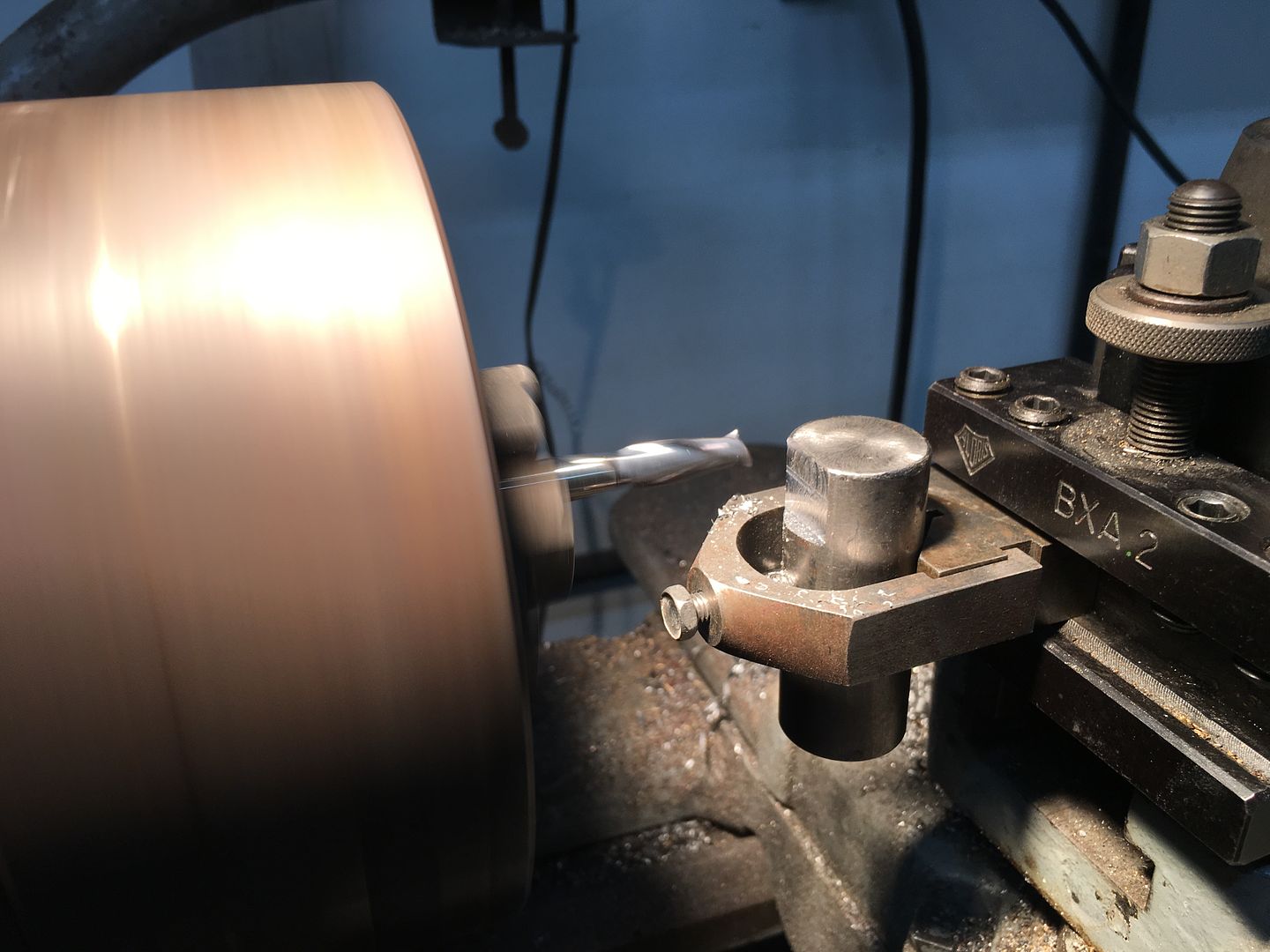

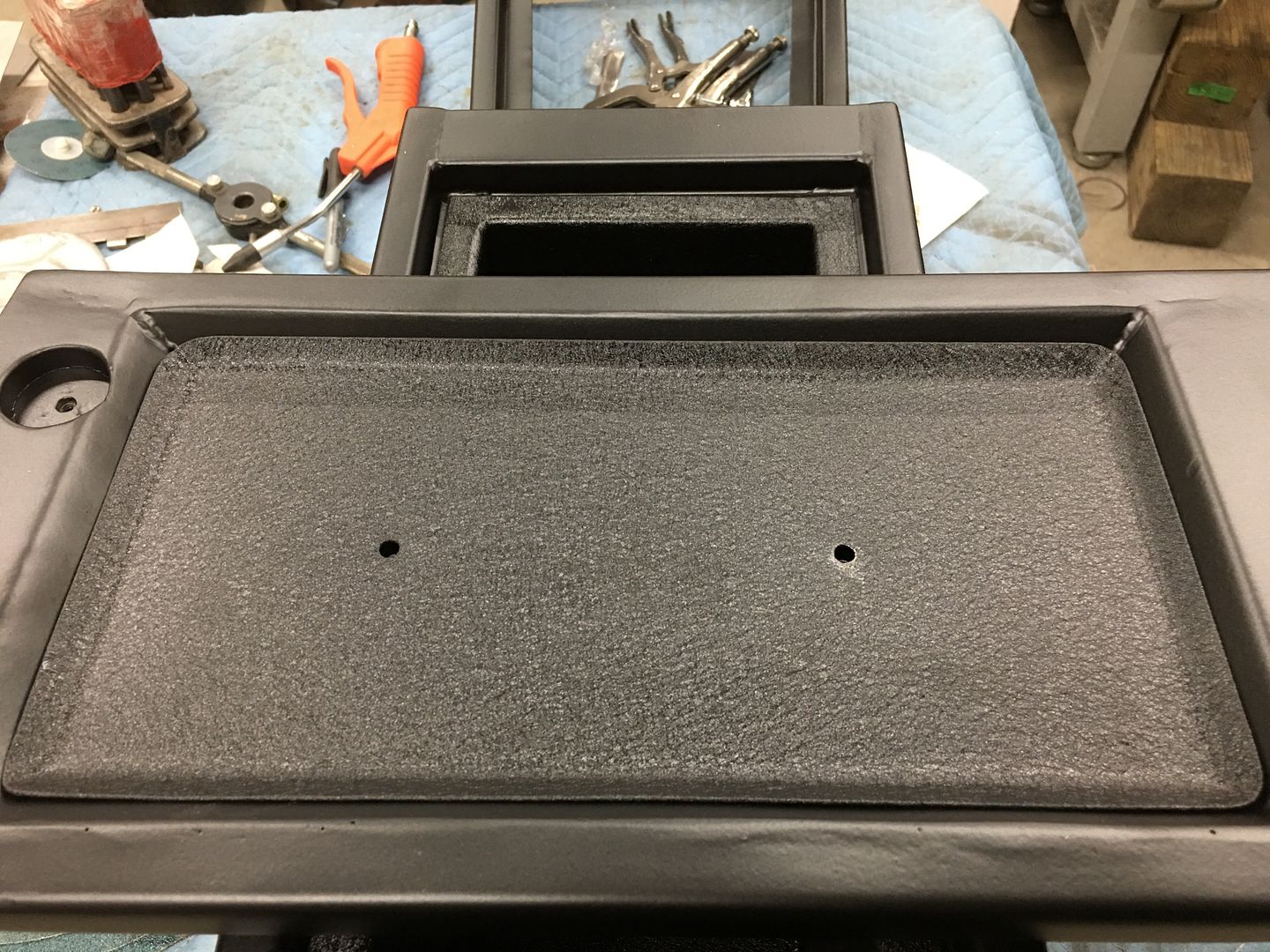

Dotting the i's, crossing the t's... The insert for the bottom side of the console lid will be held in with a couple of 10-32 screws into a rivet nut. To insure the rivet nut is flush on the outside for the installation of upholstery, we want to provide a slight recess for the rivet nut flange. Here's the punch and die we made for the occasion, the bottom die is machined on the side to keep things from moving when clamped in the vise. South Bend milling machine:    action shot: https://www.youtube.com/watch?v=Z3hS...ature=youtu.be inner parts installed...    ready for powder coat / epoxy primer, whichever comes first...

__________________

Robert |

|

|

|

|

|

#990 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,578

|

Re: 55 Wagon Progress

Looks great...after all those hrs of work it's almost a shame to have to cover it up with fabric

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#991 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,553

|

Re: 55 Wagon Progress

Robert, one very nice console...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#992 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks for the comments guys!

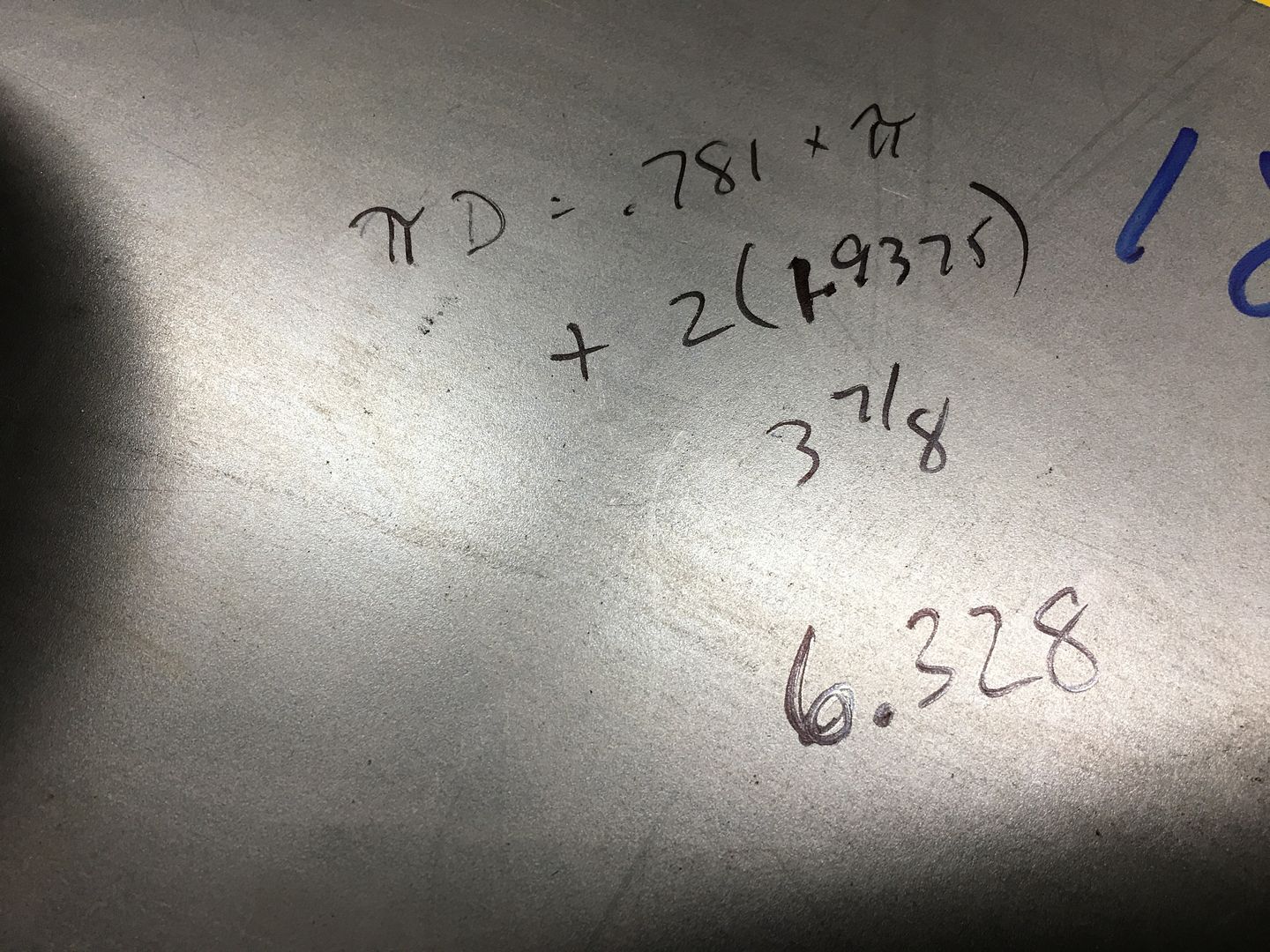

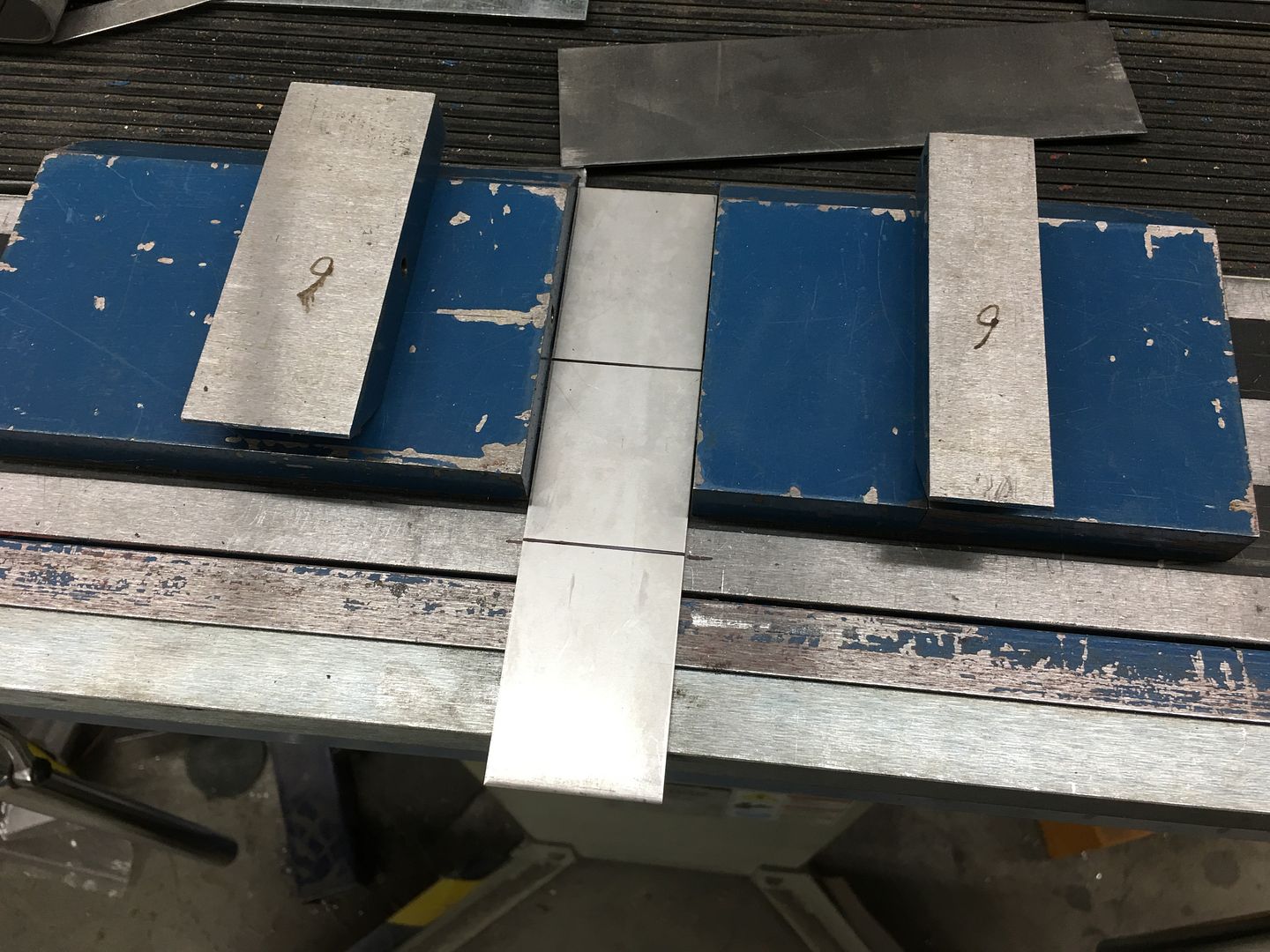

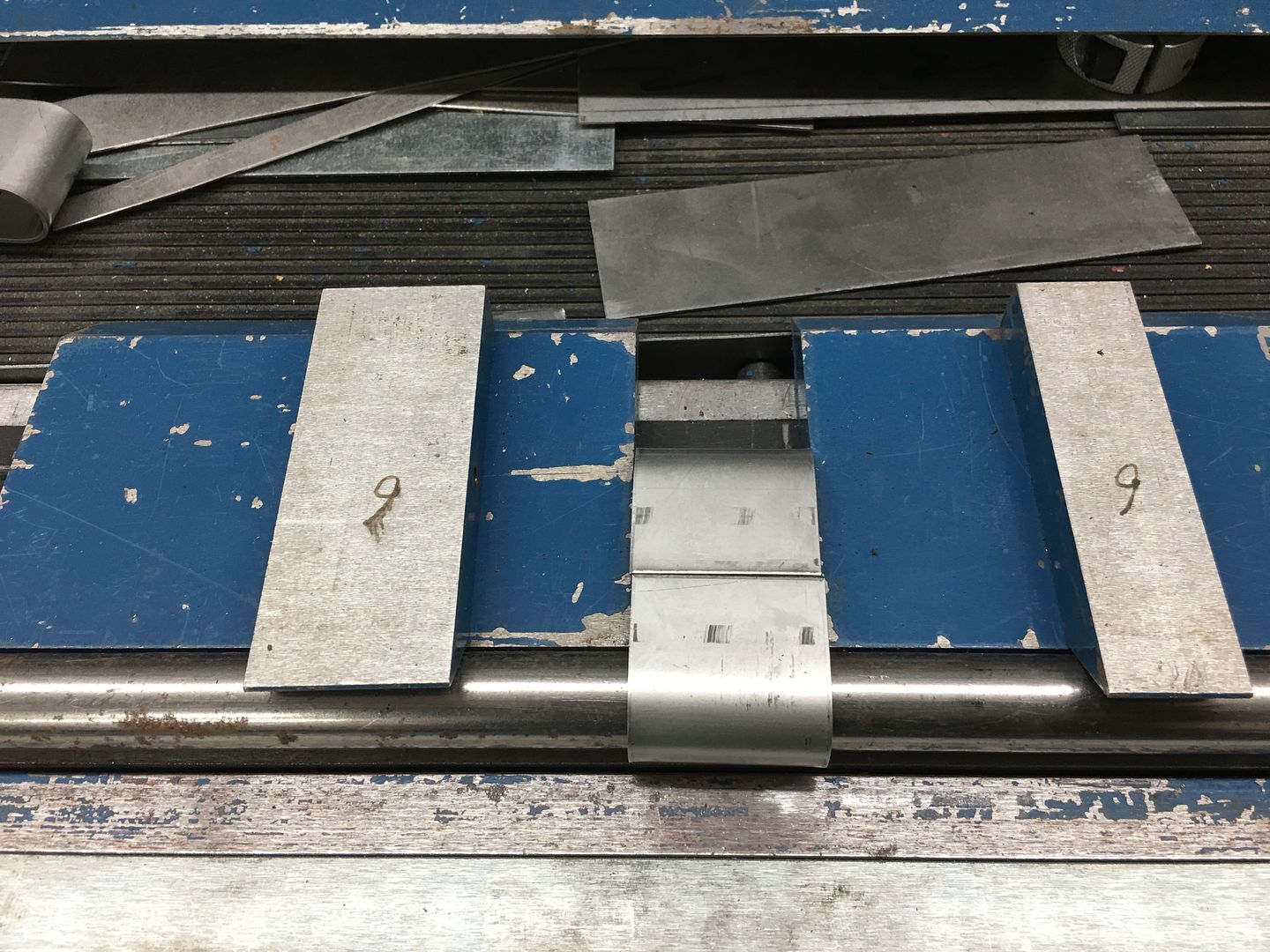

Picked up the console from the powder coater, the outside was done in satin black and will be covered in upholstery, the inside parts were done in wrinkle finish, this will be their "covering"     Tonight we worked on some stainless for our seat belt escutcheons..  Some measurements and geometry from high school should get us the correct size from the onset...   Using the mag brake and a 3/4 tube to bend our radius...    Tacked together using the TIG    Got running late and missed some pictures, but here's the part welded up and polished.. https://www.youtube.com/watch?v=b48a...ature=youtu.be .

__________________

Robert |

|

|

|

|

|

#993 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,553

|

Re: 55 Wagon Progress

Robert, very nice, both the console and finish seat belt pieces...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#994 |

|

Registered User

Join Date: Jun 2016

Location: Leatherhead, Surrey

Posts: 15

|

Re: 55 Wagon Progress

Those are stunning!!

__________________

My latest ride: https://bit.ly/2LOIoCZ SWMBO's surprise: https://bit.ly/2ouIJBD What to buy when you love old Chevy's and need an MPV: https://bit.ly/2wCobuV The daily: Now a Ford Ranger Double Cab - First road trip here: https://bit.ly/2owS24d GRIZZ, CRAIG and DENNIS’ 2018 Humdinger of a USA Road Trip: https://bit.ly/2Ca3jB4 |

|

|

|

|

|

#995 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks guys! First time at making some of these trim parts, real pleased with how they're turning out!

More progress, Mike installed the driver seat so we could mock up the lap belt for locating the lower escutcheon.   Then we contemplated vertical or parallel....   Remaining escutcheons were welded up...   Ideally the inner opening of the ring should rest on the midline of the sleeve. This provides for a good fusion weld and starts the formation of the radius we're looking for around the inside opening. Here's the various stages of welding the escutcheons: https://www.youtube.com/watch?v=jGklrvD4L6o Mike got the remaining openings cut in the arm rest and kick panels for the escutcheons...    Test fit...   …..and JB got started on the speaker trim rings for us...  The recess on the rear is for the stainless mesh...

__________________

Robert Last edited by MP&C; 01-14-2019 at 10:01 PM. |

|

|

|

|

|

#996 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Last night I tried to tackle the wizardry of filming the gas welding with the goal of better visibility of the weld puddle. This is about as close as I can get with using a iPhone camera and a welding helmet lens. Also made use of a Milwaukee LED light to brighten things for less of a change in light.

These are filmed through the Miller Digital Elite, Weld setting 9, delay 2. sensitivity 6. I think I still need to come up with something better, especially for showing any TIG welding. Are there any Photography guru's that can steer me in the right direction for filming weld processes? Tacking: https://www.youtube.com/watch?v=lo3npncFfDM Weld pass: https://www.youtube.com/watch?v=LL4i0fqr4BE

__________________

Robert |

|

|

|

|

|

#997 |

|

Registered User

Join Date: Apr 2015

Location: Port McNeill, B.C.

Posts: 464

|

Re: 55 Wagon Progress

Your work is truly amazing! I have been watching this build for awhile now and I am always impressed and intrigued by your work and methods. I would love to have your attention to detail and expertise put onto my rig!

Well done! |

|

|

|

|

|

#998 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,633

|

Re: 55 Wagon Progress

Thanks for the kind words!

Did some mockup of the fuel lines so we could get the required fittings identified..    Finishing up the polishing of our seat belt escutcheons.. after using roloc scotchbrite pads to clean up the vixen file marks, we then used 320 dry, 1500 wet, and 3000 trizact damp. Then to the polishing..     https://www.youtube.com/watch?v=zBaVKe1aBhQ Here's the comparison between the 3000 and after polishing..  That should do for us..

__________________

Robert |

|

|

|

|

|

#999 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,553

|

Re: 55 Wagon Progress

Robert, looks great...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#1000 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,578

|

Re: 55 Wagon Progress

Those shore are purdy Robert!.......

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|