|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: Jul 2009

Location: Miami, FL

Posts: 85

|

Re: 87 TBI to Carb conversion

Guys - I do really appreciate all your valuable feedback.

I'll preface this by saying I'm clearly no mechanic. So it's going to seem like I'm wasting my time, money and space a bit. Update: I got the truck back. The guy that helped me out with it is a good guy, but I'm not sure he had everything he needed to really solve the problem. Honestly, not sure he did much but to take wild stabs in the dark frankly. He replaced a Holley Throttle Body with some factory TBI he found. He says the model number matches the OEM for my truck. He also told me the temp sensor (which is brand new and you guys pointed for me) is disconnected now and I learned so is the Map Sensor (which is a swap). He said and (I confirmed) , the truck will not run with either connected at this point.  I have a bag with all my old parts. I have a bag with all my old parts.The truck is running, but clearly things are not entirely right. That said, the truck has never run l or idled as well since I've had it this past year. When I picked up the truck last night it was out of gas and it was dark, so when I would hit the gas it looks like the pump would suck air and choke. If I kept one foot on the accelerator and hit the gas it would feel pretty strong.So I had it towed home (AAA - It has no tag) and added fuel on the trip home. This morning, It started right up and drove it. It has not driven that well in months. I uploaded a video of this test drive. I'm sorry, it's annoyingly bad with the camera focusing on the steering wheel and gauges for too long. But will give you a picture of how it's running. I'd like to also go back and append to my original question, Would it be a terrible idea to mount a Carb on top of existing intake? I have a 3704 EdelBrock TBI intake. Even possible? Is there an adapter? too restrictive? What carb? This guy agreed to do the install cheap.  I understand I can get rid of all that electrical/sensory and mysterious crap, but I will need to add an external fuel pump. I understand I can get rid of all that electrical/sensory and mysterious crap, but I will need to add an external fuel pump. Many Thanks again for any ideas or suggestions!

__________________

----------------- JC (Cyberpine) My 1987 C10 Short Bed (click on slideshow to see full album) Last edited by cyberpine; 10-01-2010 at 12:22 PM. |

|

|

|

|

|

#2 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: 87 TBI to Carb conversion

Quote:

If you are dead set on going to a carburetor I would get a new carb intake for the center bolt heads. You may be able to find a used one but I don't believe Chevy made very many of them. The only one I can think of is the 87 & 88 Monte Carlo & El Camino that were still running Q-Jet carburetors when everybody else went to TBI. There are aftermarket ones out there but aren't very common as a used item.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Nov 2000

Location: Ft. Mill, SC USA

Posts: 931

|

Re: 87 TBI to Carb conversion

Subscribed! I have a 454 TBI I will have to figure out the rough idle on soon.... Good info here!

__________________

PROJECT TRUCK: 1985 SWB C10 Silverado Black/Charcoal, 1990 V2500 Suburban, 2018 Suburban, 2005 GMC 2500HD CCSB, 2014 Toyota Camry SE, HAD.....1968 Camaro RS/SS Family owned since new; 350 3 speed  SOLD SOLD

|

|

|

|

|

|

#4 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 TBI to Carb conversion

Quote:

1) That 'mechanic' is a hack at best, but least he installed some different parts to see what works, what does not. Stay away from him - he has no clue how TBI operates. 2) By disconnecting coolant temperature sensor (CTS) ECM sees high CTS voltage which is equivalent to very cold temperature -40C. At -40C ECM will call for very rich mixture - this why you feel the power from engine. 3) By disconnecting MAP sensor ECM is forced into a limp mode (SES light is on continuously) Without MAP sensor input ECM uses TPS as its only source of engine load information available. It's ability to control fuel delivery is very limited. 4) TBI camaros were equipped with similar LO3 engines. So, if he really pooled TB unit from camaro it should have correct size injectors -2x 50lb-Hr which is adequate for a stock 305. (I would verify this soon, but its ok for now) 5) The hissing noise you are hearing is probably (It tough to be certain without being there) from a fully open, stuck IAC. This would explain very high idle 1100 to 1200 RPM. 6) I am also guessing that your 'mechanic' also screwed around with base timing by moving from 0 deg to 20. In limp mode ECM fixes timing to a constant value. He probably over advanced timing to get it to run without MAP and the moment MAP is reconnected ECM tries to control timing by advancing as it normally would which way too much - ECM has no idea that base timing is way off - killing engine in the process. Analysis a) Fuel system appears to deliver enough fuel. b) Sensors MAP, TPS, CTS - remain questionable, but appear functional c) IAC - operational - should be verified. --------------------------------- Things to do 1) Reconnect all sensors plug CTS back in, reconnect MAP, make sure all other hoses, plugs are fully plugged in. 2) Perform POST = Power on self test. Move ignition key from Off to Acc to Run position - SES light should go from Solid ON - blink off - solid ON (do not start engine) Fuel pump should turn on for about 2-3 seconds and shut off. This would indicate that ECM is operating normally by being able to read EPROM contents. - Turn off ignition 3) Locate ALDL connector - it is located just under steering column. It looks like this:  4) Pulling DTC codes with a simple paper clip. Insert paper clip into socket pins A & B (usually upper right corner) shorting the two togther. Turn ignition into run position, but do not start engine.  Observe SES light. If there are no DTC codes set SES will blink code 12 three times. If there are DTC codes set each will be flashed 3 times in ascending order, pause followed by the same sequence again. So, for example of CTS and MAP are disconnected DTC 15 and 33 will be set: 12...12...12....15...15...15....33...33...33 12 12 12 15 15 15 33 33 33 and so on. At the same time ECM will command IAC to fully closed position, which you can verify by observing IAC pentacle closing idle air passage - from the top looking down (sorry, I do not have photo handy right now - will post tomorrow) Perform this simple test and post what you see (and please stay away from that 'mechanic') . //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jul 2009

Location: Miami, FL

Posts: 85

|

Re: 87 TBI to Carb conversion

Thanks RF,

Sensors back on. I do hear the gas pump or something turning on. I think I'm reading 15 and 34? I might need to do it again as there might be more codes. All of that and see how it runs with sensors on.

__________________

----------------- JC (Cyberpine) My 1987 C10 Short Bed (click on slideshow to see full album) Last edited by cyberpine; 10-02-2010 at 10:08 AM. |

|

|

|

|

|

#6 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 TBI to Carb conversion

Quote:

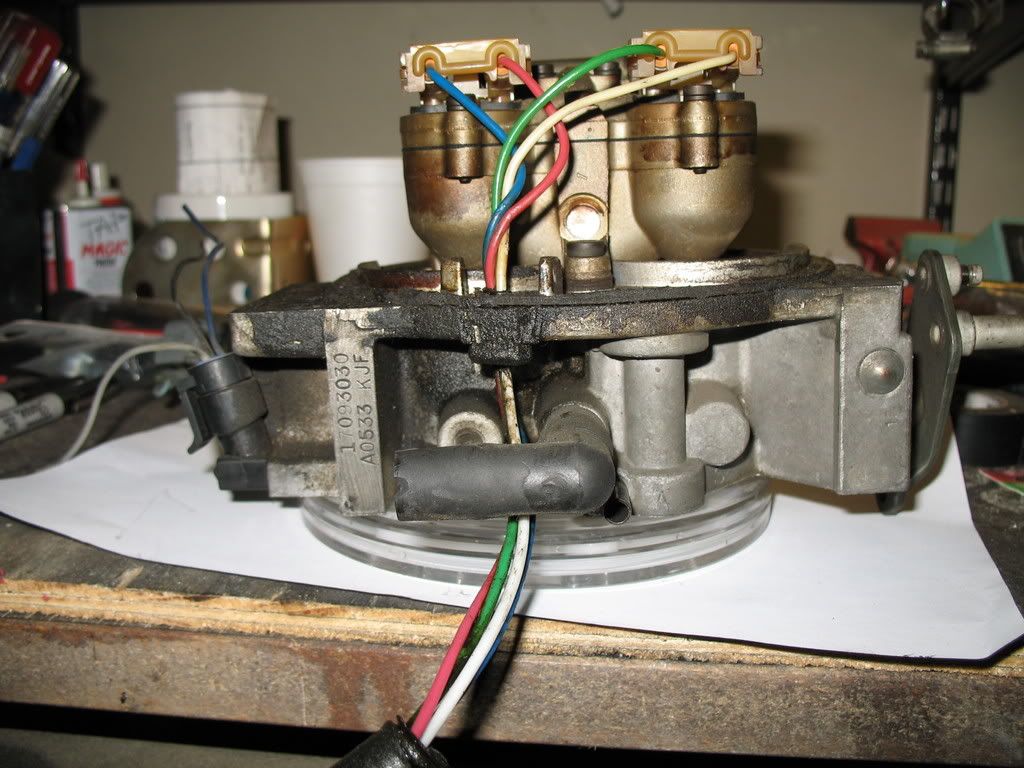

You are in relatively good shape. You have codes 15 and 34 (unless you have additional codes). In your last video you've started your engine with A+B shorted (note rapidly flashing SES light). This is a limp mode - ECM ignores sensor inputs and works from a fixed set of values. It is not advisable to drive a truck - it is design for emergency operation only. As for the codes we know what they are: 15- coolant sensor or circuit/ low temp indicated 34- manifold absolute pressure (map) sensor signal voltage low 1) Lets clear all those DTC codes as they were artificially induced. This is easily done (engine off) by disconnecting negative Battery terminal for about 30 seconds. ECM will clear its fault memory from these codes until it sees subsequent fault conditions. 2) After clearing ECM fault memory we need to make sure that IAC (Idle air) is correctly reset and knows where it is. The procedure is very simple: a) Place ECM into diagnostic mode by shorting pins A&B - this will force ECM to command IAC to continuously move into fully close position. b) Without starting engine, ignition in run position you should be able to hear clicking noise from IAC being jammed into full close position. You can see IAC pentacle fully closing idle air passage in the TB (10 o'clock). c) Remove the connector (It is 4 wire arranged in box) from the IAC and start engine while monitoring idle speed. Minimum idle speed for a stock engine should be around 450 rpm (can be adjusted). d) Shut of engine, remove A+B jumper, re-connect IAC connector. Restart engine - idle should be around 600-650 RPM. Provided that base timing is correctly set and there are no vacuum leaks. 3) Take a look at the base of TB - there should be a (black) gasket between it and intake. I have bad feeling that it is a used one and it's leaking as I doubt that 'mechanic' installed a new one when he installed F-body TB on. It is worth replacing just to make sure. While looking at TB write down its OE part number - it is stamped on passenger side vertical ledge. You can see it in this photo (17093030):  from this part number we'll be able to determine which base gasket we need to get. 3) You'll need a timing light and distributor wrench to adjust base timing.  Without this wrench getting to distributor clamping bolt in the back of the engine is real PITA. It is also possible that your 'mechanic' did not tightened and distributor can be easily turned. Check it out. I'll have to get a timing light - you must have friends that are gear heads?? Borrow, beg or rent one for now. I'll make no further comments about having no tools - everyone's situation is different. If you are able to secure timing light and twist distributor (aka dizzy) setting timing is easy. You'll have to locate EST connector - it is a single wire connector (usually tan/black or brown/white wire) in the harness near Power brake booster. This connector by-passes the electronic spark timing controlled by ECM and allows the initial timing to be adjusted by rotating the distributor. Use the following procedure (become familiar with entire procedure before beginning): The ignition timing marks are located on the engine's front cover. A big notch slot on the balancer indicates engine is at (TDC) Top Dead Center. Adjust ignition timing as follows: You truck is specified at 0 TDC base timing <> Connect a timing light to the number one (1) spark plug wire - it is closest to the front on drivers side. Connect the timing light power lead to a 12 volt power source - Battery terminal. <> Start engine and allow to warm to operating temperature. Bring engine to idle (650-800 Rpm). <> Disconnect EST connector - idle speed will drop down (it is normal) <> Point timing light at the balancer while rotating (slowly) distributor to set mechanical timing. Look for slot on balancer to line-up against biggest notch on the timing tab. It is 0 degrees <> Tighten distributor clamp to hold in position when initial timing is obtained. <> Recheck timing. <> shut off engine and reconnect EST connector. You'll have to disconnect battery for about 30 seconds again as DTC code 42 will be set by ECM - this is normal. After clearing ECM re-start engine. It should idle at about 650 RPM and if you check timing it will be bouncing between 18 and 22 degrees as ECM will be providing continuous timing control. Alright - can handle this???? Questions??? No need to be afraid. BTW your videos are superb. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jul 2009

Location: Miami, FL

Posts: 85

|

Re: 87 TBI to Carb conversion

Sir - You have been incredibly generous with your time and expertise.

I've got a new android phone that lets me post right up to youtube and picasa (all 3 are google products so it's incredibly seamless) I've read your last post 3 times now and have a printed copy in hand. It's going to take me a few days to do this and will likely run into next weekend ... but am going to do it! a I almost can't wait to reach my limits . I think setting the timing on the truck will be the most ambitious task I've ever performed on a car or truck. A few months back I changed the shocks and brakes on another truck and was impressed that I was able to do that. Somewhat off topic (warning may want to skip) About my level: I'm not without some mechanical skills. I think I'm much better with construction stuff like plumbing and home electrical than I've ever been with engines. Don't need to state the obvious that home repair has nothing on the complexity of a combustion engine and all the crazy wiring, sensors, etc. But anyways (rambling on now) my background is not even in construction either - I'm a software developer building Web and Database backends and I can tell you that science is pretty crazy and deep too and I know that some of the crap I've had to reverse engineer and build rivals whatever mysterious flowchart stands between me and a success on this one. For me, personally, I don't think it's about the grasping how this might work - granted trying to grasp that from some manual is tough and usually what separates the men from the boys I'm sure. For me (like many I'm sure) it's probably more about patiences and organization. I'm a freakin mess with my tools. I probably own (no lie) 5 hammers and 10 messuring tapes. When I feel the rare urge to work on the truck, It burns to find the right tool (which I know I own 2 of) , so I end up stripping something or f*ing something up even worse. I will confess to having done some task that a novice should never do for the a 1/3 of the price, but 3 times at that price to finally get it right. And To me - that's a GIANT win. Back on topic.. . Yeah a bit scary and certainly outside my comfort zone. Got nothing to lose. Thanks again man .. here's my next video

__________________

----------------- JC (Cyberpine) My 1987 C10 Short Bed (click on slideshow to see full album) Last edited by cyberpine; 10-02-2010 at 07:08 PM. |

|

|

|

|

|

#8 | |||

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 TBI to Carb conversion

Quote:

Quote:

I do not want to sound cavalier, but in the end, looking back at it, it all will be straight forward. The key to success is a state of mind, preparation, organization, time to do it correctly the first time, and tools. Quote:

//RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|||

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jul 2009

Location: Miami, FL

Posts: 85

|

Re: 87 TBI to Carb conversion

had about 20 minutes this morning..

The two codes 15 and 34 are the only being reported. The mechanic mentioned he kept the original injectors and said he did not use a gasket between the tbi and intake, but rather some special red paste. Injectors appear to shooting well. here's some pics and a video. Thanks.

__________________

----------------- JC (Cyberpine) My 1987 C10 Short Bed (click on slideshow to see full album) |

|

|

|

|

| Bookmarks |

|

|