|

|

|

|

|

#1 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

//RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#2 |

|

Registered User

Join Date: Feb 2010

Location: el paso, tx

Posts: 510

|

Re: Tbi swap build thread

Happy New year everyone.

Im in search for a External Fuel Pump for the TBI set up. Fuel pressure is 13-16 right? |

|

|

|

|

|

#3 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

If you search the thread - 1st couple of pages - there are suitable FP listed. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Nov 2010

Location: Ishpeming, MI

Posts: 36

|

Re: Tbi swap build thread

What is the charcoal filter for? Is it really needed in a off-road rig? Can I just plug off the lines ?

|

|

|

|

|

|

#5 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

A charcoal (filter is not a correct name for it) canister is used to trap the fuel vapors. The fuel vapors adhere to the charcoal, until the engine is started, and engine vacuum is used to draw the vapors into the engine, so that they can be burned along with the fuel/air mixture. This system requires the use of a sealed gas tank filler cap. In grand scheme of things 20% of all HC emissions from a car or truck are emitted from the gas tank! In a way this system saves loss of fuel due to gasoline evaporation inside the gas tank. Diagram below is for a carburetor based system - TBI is very similar.  The system does not rob any performance from the engine and as a benefit captures and burns gas fumes that otherwise would have been lost into atmosphere. Since it costs very little I use it on all my projects. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: May 2007

Location: East Haven, CT

Posts: 882

|

Re: Tbi swap build thread

I love TBI!

__________________

87 Chevy 2wd SWB: 305/700r4 Dual Exhaust, K&N Filter, Injector Pod Spacer, TBI Spacer, Belltech Front Sway Bar, Corvette Servo, Western Chassis 4/6 and c-notch |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2010

Location: Ishpeming, MI

Posts: 36

|

Re: Tbi swap build thread

well I changed my mind on some of my wiring and I am going to install a relay ....

This is the way someone else has the relay wired 30-12v fused input(should also hook up your org ECM constant 12v to this wire) 85- Gnd 86- 12vdc from ign sw(black wire that was hooked up to the coil +) 87- pink/blk, pink(r) 87- red, white(injectors) I have done reading and came across this its about halfway down the page their is a demo . http://www.bcae1.com/relays.htm The way I understand the demo 30 is + from battery along with org ECM constant 12v 85 should be + from coil (key run/start)? 86 should be - from coil 87(A?) ignition, ecm power key off ? 87 injectors key on/run? Last edited by Chad77; 01-07-2011 at 03:42 AM. |

|

|

|

|

|

#8 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

//RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#9 |

|

Master Hater

Join Date: Apr 2006

Location: Temple,Tx.

Posts: 402

|

Re: Tbi swap build thread

Nice tread, BUT ,... to anyone who does this later on. Make sure you take the time and swap out the heads, That is the biggest limiting factor for making any kind of power on TBI engines.

You can see how the ramp blocks half the intake port.  This is a regular intake port. You can see how much better this is.

__________________

1997 C1500 ECSB 4.3/NV3500 8.5 3.42 "This evening, all of you bleeding hearts... why don't just go ahead and hug yourself for the next 20 minutes or so, because there's a really good chance you're gonna be offended".- Captain Owen Honors Last edited by ironroad9c1; 01-09-2011 at 07:34 PM. |

|

|

|

|

|

#10 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

If you don't have the money for a head swap then just a cam swap will make a huge improvement as long as you can tune for the changes it will make in the engines operating parameters.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jul 2010

Location: Fremont, CA

Posts: 1

|

Re: Tbi swap build thread

Hello everyone,

I have just about finished a '91 4.3 swap into my toyota and this thread has helped me out a whole lot. At the moment I am having a few issues. When I start the truck it runs fine. When I rev up the engine and let off the gas the RPM's drop quickly, but once the engine warms up to operating temperature when I rev the engine it is slow to return to idle. It does return though. Any ideas? I want to get everything in order before I have to take it to the referree station to get my new VIN sticker. Last edited by Doc Hollywood; 01-08-2011 at 09:57 PM. |

|

|

|

|

|

#12 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Before going to referee station make sure that you have ALDL connector wired and bolted, as well functional SES light. Good luck //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Nov 2010

Location: Ishpeming, MI

Posts: 36

|

Re: Tbi swap build thread

So if I understand this is how I need to wire it then?

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Yes, it should be correct - love the sketch.

Minor clean up  //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Nov 2010

Location: Ishpeming, MI

Posts: 36

|

Re: Tbi swap build thread

Thanks! I was kinda in a hurry when I posted that!

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Oct 2009

Location: Pineville Mo

Posts: 15

|

Re: Tbi swap build thread

Great thread! I've finally read through it all. Lots of good info. Pretty much every question I had was already answered. I've messed with TBI engines a bit and I'm pretty familiar with the components and their functions. After much reading and research I've just started my own project and with the help of this thread I've got my donor harness rewired for my application. It's a 92 454 harness originally equipped with an auto trans. Here's my first hangup. There no wire in the B7 pin. The first page of this thread indicates that this is designated "ESC, Knock Sensor signal to ECM". This harness has no ESC or KS plug in the harness. The harness had not been tampered with. Is the ESC not necessary?

Great diagrams and schematics!!!

__________________

1976 Chevy Crew K2500 NV4500/NP208 454 3:73 gears/rear posi |

|

|

|

|

|

#17 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Some of 454 HD applications did not use KS and ESC module. These 454 HD (BCC) calibrations deliberately keep spark advance low thus keeping engine from knocking when under load. The purpose of KS and ESC module is to provide indication back to ECM when engine knock is occurring. The question is what you're trying to do with your TBI swap - i.e what engine are you trying to EFI (350/454) and trany? IRC HD 454 calibrations were used on on 3/4 and 1 ton trucks. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#18 | |

|

Registered User

Join Date: Oct 2009

Location: Pineville Mo

Posts: 15

|

Re: Tbi swap build thread

Quote:

What it the function or purpose of the red/white wire coming out of the FP relay? It's labeled "fuel pump prime" and diagrams show it terminating at what I assume is supposed to be a plug connector. This wire was ran into a connector that contained the auto trans wires, and I couldn't find a diagram for that connection. Other than that, I think everything is looking good.

__________________

1976 Chevy Crew K2500 NV4500/NP208 454 3:73 gears/rear posi |

|

|

|

|

|

|

#19 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

//RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#20 |

|

Slots go on anything!

Join Date: May 2003

Location: Richardson, TX

Posts: 5,957

|

Re: Tbi swap build thread

I am on the downhill slide of my swap also. I fired it tonight, but it is idling terribly high. My TPS is showing 1.18V @ idle, that's the lowest it will go. I will swap it out tomorrow. Will the high TPS voltage cause a really high idle?

__________________

1974 Jimmy- 5.3/4L80e/NP241 |

|

|

|

|

|

#21 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

You may want to reset IAC - there is a set of instructions (use search ) to bring idle speed down. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#22 |

|

Slots go on anything!

Join Date: May 2003

Location: Richardson, TX

Posts: 5,957

|

Re: Tbi swap build thread

Thanks RF. I am having a little trouble running down an adjustable TPS, (The two I have at teh house are non adjustable units too), but I just started early this morning. The drivability guys at work think it may be thinking I am on the throttle with the high TPS, and backing the IAC out as a result. We will see how it goes tonight with a new TPS.

__________________

1974 Jimmy- 5.3/4L80e/NP241 |

|

|

|

|

|

#23 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

IAC is used to add air bypassing throttle plates to control idle speed. TBI ECM has no idea about actual IAC pintacle position. It has to calibrate its position by commanding IAC into fully closed position on reset (0 step count). After reset ECM will command IAC into wide position (160 counts in most calibrations). During start ECM will move from full open toward reduced air bypass. 1.18V TPS is just of idle - so ECM may increase IAC counts. Do you 454 injectors on top of 350 engine?? Does your ECM has 454 calibration (BCC)?? //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#24 |

|

Slots go on anything!

Join Date: May 2003

Location: Richardson, TX

Posts: 5,957

|

Re: Tbi swap build thread

I bought the engine and trans as a package from a friend here. The engine was replaced ~15K ago, but the stock TB and injectors were still in place. The injectors are 350 units as far as I know (he was wanting to upgrade them before he went to LS power). I did add a TB spacer, since it came with all of the parts. I will definitely check the min. idle screw; I had to somewhat assemble the TB, so it's entirely possible it has been moved. I am having a little trouble running down an adjustable TPS, though. Has anyone opened up the mounting screw holes to allow for any TPS adjustment? I thought maybe there was room for a Dremel tool (or similar) to get in there.

__________________

1974 Jimmy- 5.3/4L80e/NP241 |

|

|

|

|

|

#25 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

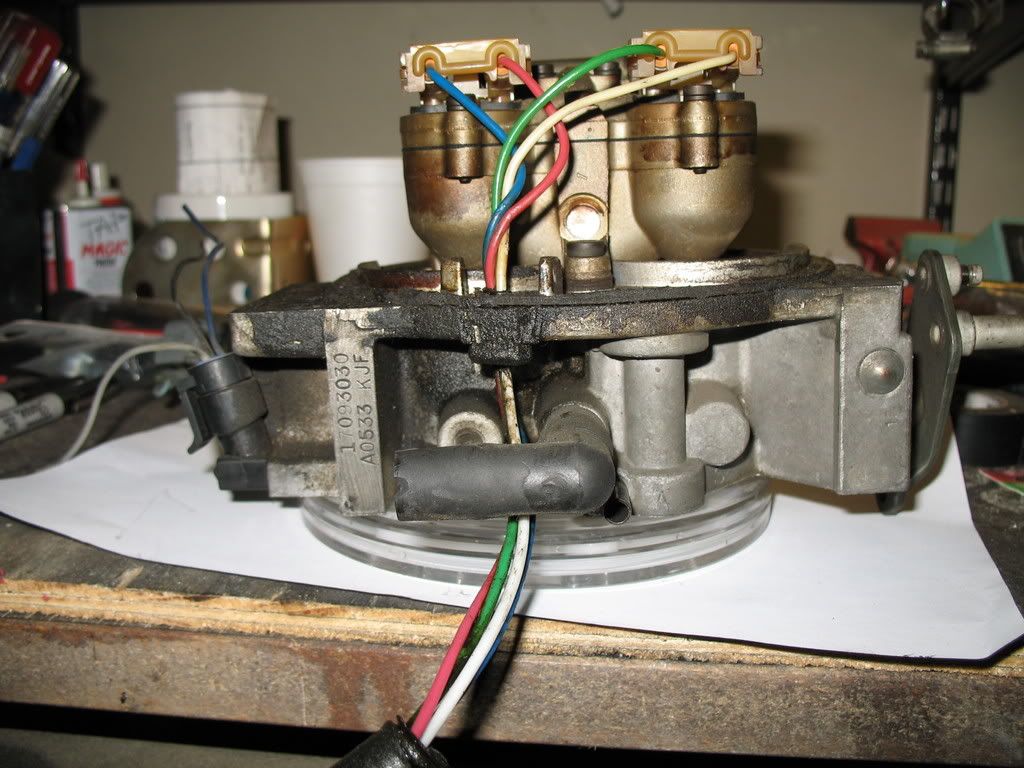

To put this issue to bed please post TB service number stamped on the left front and ECM service and BCC numbers:  In the photo above TB service number is 17093030 Non adjustable TPS:  SBC TB 17093030 Early 87-90 BBC TB  Note different style IAC connector and large size TPS connector Vacuum port identification - some TB's may not have them all

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

| Bookmarks |

|

|