|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Mar 2014

Location: Wichita

Posts: 516

|

DIY Exhaust - Cutting Tubing

Ok, what are you guys thoughts on exhaust?

Some will probably say, "take it to a shop", but I've done everything else on my truck myself. And I kinda want to put in motorized dumps. So I'm thinking about a kit like this: https://www.speedwaymotors.com/Unive...nch,36340.html And I had this great thread saved on how Hussey cut his tubing. http://67-72chevytrucks.com/vboard/s...=664837&page=2 But I don't have a metal band saw like that, and frankly don't have room for one. Do any of you guys have a great way of cutting exhaust tubing with another tool? |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jun 2017

Location: upper midwest

Posts: 1,129

|

Re: DIY Exhaust - Cutting Tubing

I used a similar kit from Summit Racing, it worked out very well. I used a cut off wheel for cutting, using a piece of masking tape around the pipe as a guide. You can fine tune the cuts with a grinder.

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

I've built maybe a half-dozen header/exhaust systems over the years - I'm no expert but here's what I do.

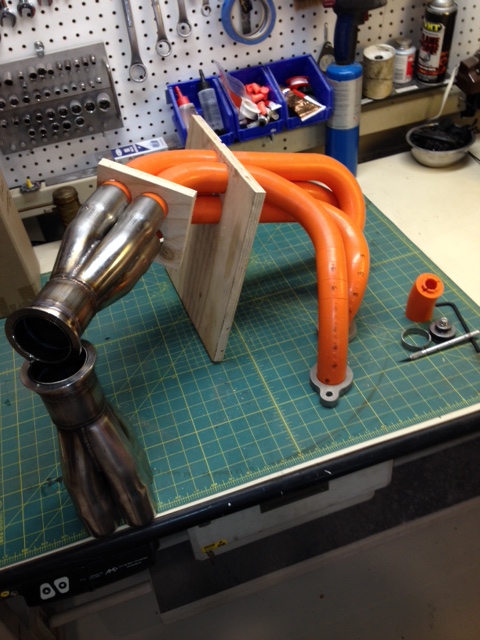

You want all your joints to be square so when you mate them together there's no overhang or lip. To do this I take a radiator clamp and place it over the tubing straddling the line I need to cut. I mark it with a sharpie on both sides of the clamp, remove the clamp and draw a cut line between the two lines I marked. This works for straight tube or mandrel bends. To clamp straight pieces or a mandrel bend to a straight piece of tube, I have a home-made tube clamp made from a worn out vice grip and angle iron from an old bed frame. Here's what it looks like  For joining mandrel bends, I have a set of these. A little spendy but if you are doing a lot of complicated bends, they're worth it. These are for primary tubes but I imagine you can get them larger too.  I've made jigs similar to Hussey's too, but I've found it is quicker to cut them freehand. I've done it on a band saw, die grinder, angle grinder and cutoff wheel and a hack saw, but the easiest and fastest way I've found is with a Portaband in a SWAG table. (Get one and you'll wonder how you lived without it) A HF portable bandsaw and a home-made stand will do the trick too. Put a HF foot pedal on-off switch on it. Once the tube is cut, clean it up and make it flat on a belt sander - you shouldn't be able to see any light through the joint. I have a floor model but you could rig a portable beltsander to do the same thing. Every once-in-a-while you need a little 'cheat' to make a tube align perfectly by grinding it off-tangent a bit and a belt sander works wonders. No tube is perfectly straight so I try to put the tube clamp on such that you can put a tack where the tubes meet there is no lip. Keep moving the clamp around to minimize the lip and tack it every 90 degrees. I do my weld with a TIG, but MIG will work too and you don't have to be quite so fussy with fit-ups. With the TIG, my goal is to weld without filler. Here's a header project I did last year. Planning out the 2.5" exhaust for these headers this fall. The exhaust back from the collectors is the same principal of cut, fit-up, tack and weld.  This is the kind of joint you're looking for-

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Aug 2011

Location: Tucson, AZ

Posts: 917

|

Re: DIY Exhaust - Cutting Tubing

Nice work. What is the brand of those mandrel bend clamps? I've never seen any like them and they look slick.

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Mar 2014

Location: Wichita

Posts: 516

|

Re: DIY Exhaust - Cutting Tubing

Very cool. Thanks for the help.

I do have a bench top belt sander. And those homemade vice grips should be no problem. Do you have a pic of your SWAG table? |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

The brand is called "ICE Engine Works" and you can buy them from Trick Tools.

I've used hose clamps and popsicle sticks in a pinch but you don't need three hands to use these |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

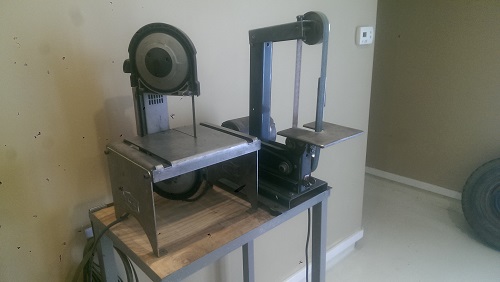

Here's a picture of a Milwaukee Portaband in a SWAG stand. The on-off switch is held down by a velcro strap and the saw is controlled with a foot pedal. There's a little belt sander next to it for deburring and smoothing cuts. I use a 17TPI bi-metal blade in mine. I buy Morse (sp?) bi metal blade for it off of ebay for cheap, but in a pinch I can use the Milwaukee blades from HD.

Here's the setup I use to true the tube. The belt is 90 degrees to the table and the fence keeps the work at 90 degrees to the belt.  It is just a Sears belt sander from CL that I put a one horse motor on so it will turn the stiff 40 grit belts I use on steel tube. |

|

|

|

|

|

#8 | |

|

Registered User

Join Date: Sep 2014

Location: USA

Posts: 2,249

|

Re: DIY Exhaust - Cutting Tubing

Quote:

My homemade exhaust systems usually come out better than a professional job because I put more care and effort into the details.

__________________

1951 Chevy Panel Truck |

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

Here's yet another way.

In a pinch I've used a pair of dial calipers to mark the tube for a cut, place the caliper over the mandrel bend and wiggle till you get the shortest distance. Mark the tube at both the inside radius and outside radius, then connect the two marks with a piece of tape, Then cut with your method of choice |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,662

|

Re: DIY Exhaust - Cutting Tubing

you won't use half the parts in that kit, we have some of the easiest exhaust to run on a vehicle

1 bend and straight tube will get you to the rear axle the shop i 'work' at does mostly mandrel bent exhaust systems all the custom and one off jobs are cut and fit just like described from others though we do have a lot of specialized equipment just for exhaust

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Feb 2010

Location: Lebanon, Ohio

Posts: 1,359

|

Re: DIY Exhaust - Cutting Tubing

X2. TIG weld works best. Take your time and you will do well...

__________________

Bob "It won't take long and it won't cost much." '55 3100 (383/700R4)--'55 Belair Sedan (350/4-speed)--'64 'Vette Conv. (327/4-speed)--'68 GTO Conv. (462/4-speed)--'69 Cutlass Conv. (350/TH350)--'06 'Vette Conv. (LS2/6-speed) Bob's Retirement Build - My 55 TF Bob's 700R4 Build (how-to) |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

Very nice looking work Dransport.

B-mac -As Ogre points out, depending on the complexity of your system, you might want to look at individual mandrel bends. I buy most of my bends from Columbia River Mandrel Bends http://www.mandrelbends.com/ |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Feb 2010

Location: Lebanon, Ohio

Posts: 1,359

|

Re: DIY Exhaust - Cutting Tubing

Eo15475, LOVE that header work! There are a ton of great ideas on this thread.

BTW, I used the stainless Pypes Universal Kit, and I sprung for a pair of these "Strong Hand Tools Pipe Pliers": (If I had seen Eo's home made pipe pliers I would have made my own though...)

__________________

Bob "It won't take long and it won't cost much." '55 3100 (383/700R4)--'55 Belair Sedan (350/4-speed)--'64 'Vette Conv. (327/4-speed)--'68 GTO Conv. (462/4-speed)--'69 Cutlass Conv. (350/TH350)--'06 'Vette Conv. (LS2/6-speed) Bob's Retirement Build - My 55 TF Bob's 700R4 Build (how-to) |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: DIY Exhaust - Cutting Tubing

Oh DAMN that's a cool clamp! WOW!

Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: DIY Exhaust - Cutting Tubing

I know I have made good patterns with thin tubing like brake lines and brought those to a muffler shop to have them make the pipe. On some tight spaces I still had to modify them but that worked.

Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

ICEngineworks sells a bunch of interesting stuff besides these clamps.

https://www.icengineworks.com/ I used their plastic 'header legos' to layout the headers shown earlier in this thread. Here's one of the mock-ups of plastic 'header legos' I did when I was considering pushing the headers through the inner fender instead of between the frame rail and the engine  I see on their website that they now have them in 2.5" diameter, so if you want to spend a bit of coin you can mock-up your secondary tubing too. They sell jigs for cutting mandrel bends too. For the most part, their stuff is too much money for a home shop enthusiast, but I could see how fab shops that occasionally did header work might find it useful. |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,262

|

Re: DIY Exhaust - Cutting Tubing

I'm thinking that Eo15475 is several levels above the norm as far as welding and fabricating go and above many who call themselves professionals. That is some beautiful work.

My experience says that you don't save any money building your own exhaust system using the right parts to do a nice job nor by buying pre-made pieces online and installing them yourself over having a quality shop do the work. If it is just for the pride of having done everything possible yourself that is ok though.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: DIY Exhaust - Cutting Tubing

Mr48, can I get a membership to your club? I am thinking I qualify.

Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 759

|

Re: DIY Exhaust - Cutting Tubing

"My experience says that you don't save any money building your own exhaust system........."

My experience says the same thing. I could have bought a couple of sets of Kooks headers for what I have in mine for just the material and coating. I had a lot of fun building them and enjoyed the challenge though. It's a bad habit of mine to start 'science projects' in the middle of a car project. BTW, I'm not 'above the norm' in fabrication ability, but have merely lived long enough (and cheap enough) to have fabricated a few sets. The first set of headers I tried making ended up in the trash can and I ended up writing a check to somebody else to fab them. |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,262

|

Re: DIY Exhaust - Cutting Tubing

You already had Vip status.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,262

|

Re: DIY Exhaust - Cutting Tubing

When I worked at Midas in the late 70's the boss cut one exhaust system I made because it wasn't up to his standards. I was hired to do the front end and brake work but they didn't have enough of that to keep me busy so I also did exhaust work and actually learne to weld there.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Dec 2000

Location: Boise, Idaho

Posts: 6,001

|

Re: DIY Exhaust - Cutting Tubing

Thanks! Do we have any shirts or patches or something we need to wear at the meetings?

Brian

__________________

1948 Chevy pickup Chopped, Sectioned, 1953 Corvette 235 powered. Once was even 401 Buick mid engined with the carburetor right between the seats! Bought with paper route money in 1973 when I was 15. "Fan of most anything that moves human beings" |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Mar 2012

Location: Lakes Region NH

Posts: 3,152

|

Re: DIY Exhaust - Cutting Tubing

I do try to build my own exhaust to save money. They way I do it is head to the exhaust guy's shop and get a bunch of scrap bends out of his steel pile. I mock up the system with scrap then bring the sample system back in and a new system is fabricated. I've never gone as far as building my own headers and every time I look at the mandrel bent "kits" with small, individual pieces the total price for the system is more than the scrap to complete system route I follow now.

I will say that I'd love to find good exhaust pipe that doesn't cost a fortune (i.e. stainless). Exhaust shop guys I talk to have the same wish. The aluminized pipes I paid to have built fo my '79 Monte back in '90 is still usable. The aluminized pipe I made for my Toyota in 2010 is junk. |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,662

|

Re: DIY Exhaust - Cutting Tubing

my experience is that you save a buttload of cash with diy exhaust if you want mandrel bent

most shops crush bend exhaust tubing, only a custom hotrod/exhaust shop will do mandrel systems a one off mandrel bent exhaust at our shop will cost you $1800 and up we do only 304 stainless cuz most of the cost is labor, aluminized would only save $100, we stock ss only i did my exhaust before the shop bought most of it's exhaust bending/welding equipment aluminized 2.5'' from summit, have less than $100 in it plus mufflers

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jul 2017

Location: Joshua, Texas.

Posts: 1,303

|

Re: DIY Exhaust - Cutting Tubing

I've been watching this thread. I plan to use my donors exhaust and I think I just need to shorten it. One cut and weld it up... wish me luck lol.

Are there any rules of thumb for exhaust clearance? Distance from cab, frame, rear axle, and the bottom of the wood bed? Should I get or use heat shields for the bed and under cab where the gas tank is?

__________________

1950 Build |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|