As mentioned previously, the original 402 bbc had been replaced at some point with a 400 sbc with a late model serpentine drive belt setup. The original big block fan shroud was present but had been modified at the bottom to clear the mechanical fan and there was a big gap at the top. This worked okay when on the road but was inefficient at slower speeds and tended to overheat at idle. And due to the previous hot start issues, I couldn't simply stop the truck when making a run to the dump etc.

Since I wanted to get the air conditioning working again, I decided to go with an electric fan and to do away with the mechanical fan altogether. After some searching I found a couple of threads where folks were using a Grand Cherokee radiator fan. I figured I would give it a shot and bought this one new for about $52 shipped to my door:

I had hoped to re-use my big block shroud but was disappointed to find the opening was too big for the 19" fan. I put a want ad in the classifieds and wound up buying a nice small block fan shroud from another member (thanks Todd68Chevy!) along with some used radiator mounts. It had a small chip in the mounting tab but otherwise looked like new once it was cleaned up.

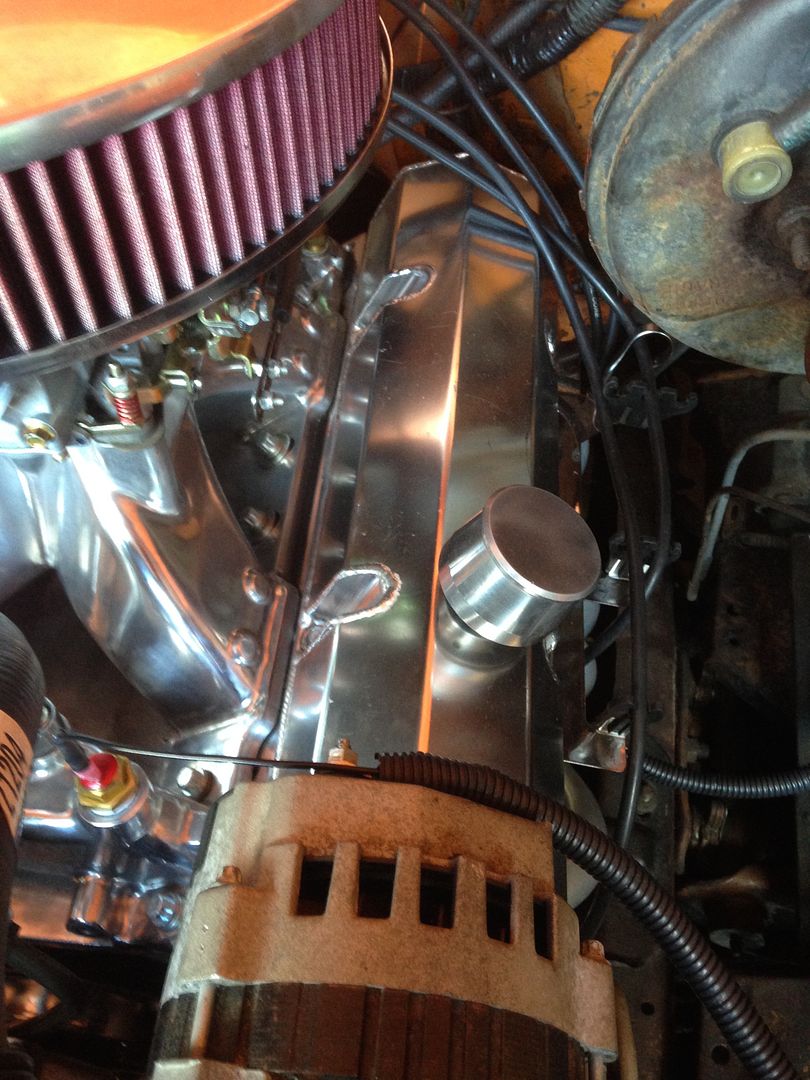

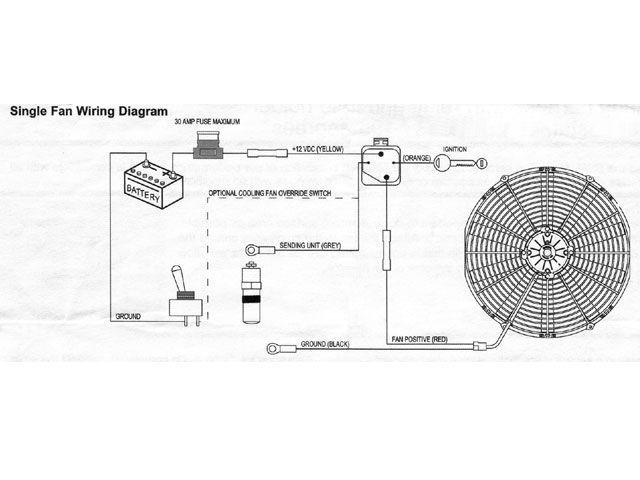

I bought a relay kit from one of the online retailers which had a 3/8 npt sensor and 1/2 npt adaptor to fit my intake manifold. I wanted to get a stainless sensor but couldn't justify the extra cost so settled for brass. I also opted for a sensor designed to turn on at 185ºF and off at 175ºF.

The instructions forbid the use of teflon tape or pipe sealant around the temperature sensor and said all kinds of bad things would happen if I used it, the least of which was a poor connection or inoperable sensor. Despite intuition, I gave it a shot and soon noticed coolant leaking around the fitting, duh. A little teflon tape solved this problem and tested fine with the multimeter so I threw the crappy instructions away and sourced a wiring diagram online instead.

I wanted to keep the relay close to the fan but in a place that was easy to service if needed. I noticed a small rectangular recess on the inner fender which seemed ideal for the relay base so put it there. The 30 amp circuit breaker was then mounted between the fan relay and remote starter relay and wired together.

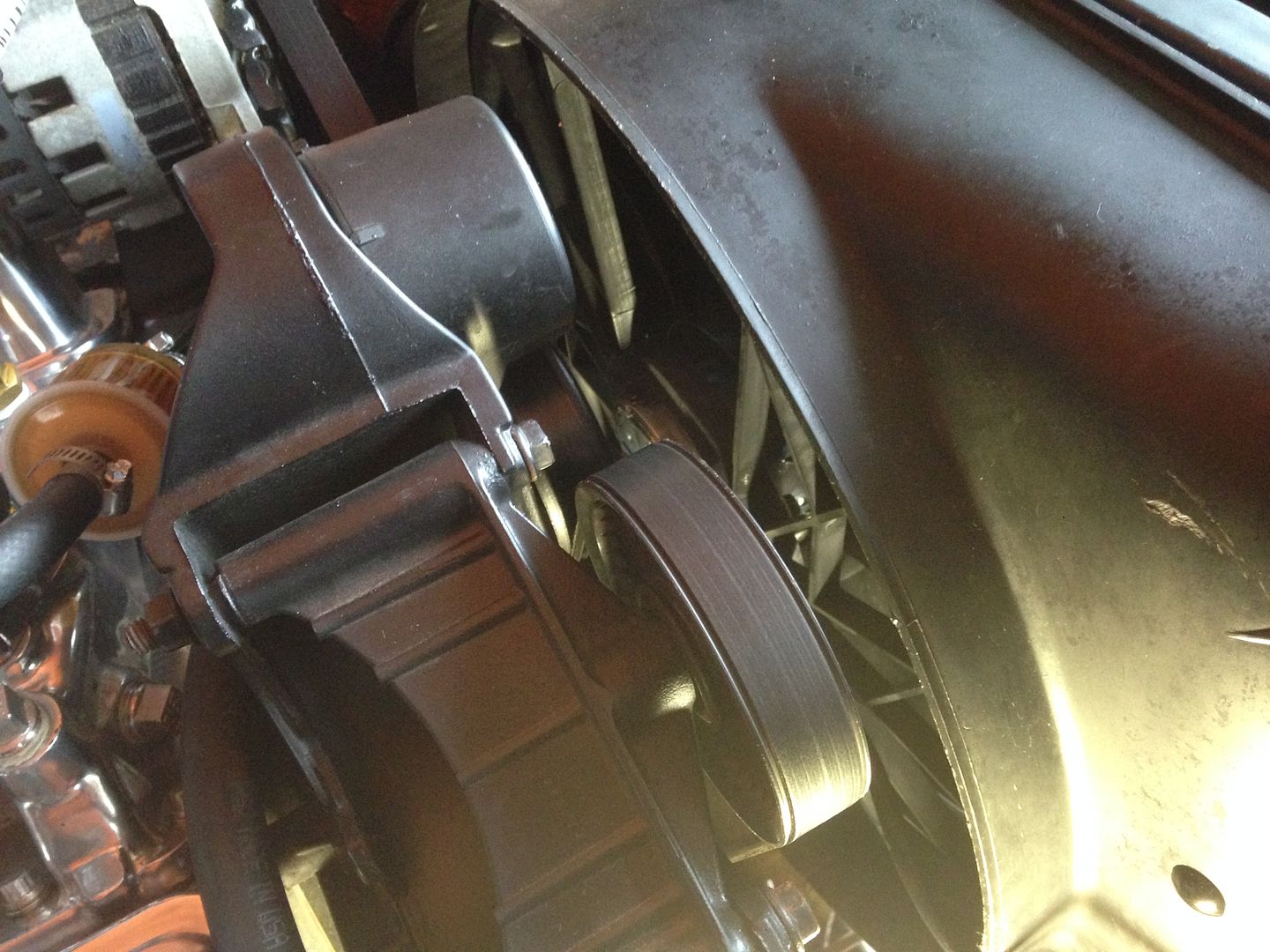

As for the fan, this was mounted by cutting a C-shaped slot on the bottom of the shroud which was centered from front to back. This was done by drilling small pilot holes then cutting it with a saber saw using a fine blade. Finally, holes were drilled on either side and the fan was mounted using two bolts. I suppose one could add a bolt to the bottom but if you saw the setup you would realize that lower tab is not going anywhere.

Initially I was disappointed to find the new fan housing was touching the bolts on the water pump pulley. I wound up having to go back and shim the fan away from the motor using fender washers as well as eliminate the washers and lock nuts on the pulley. In the end I wound up with 1/4" of clearance which is just enough.

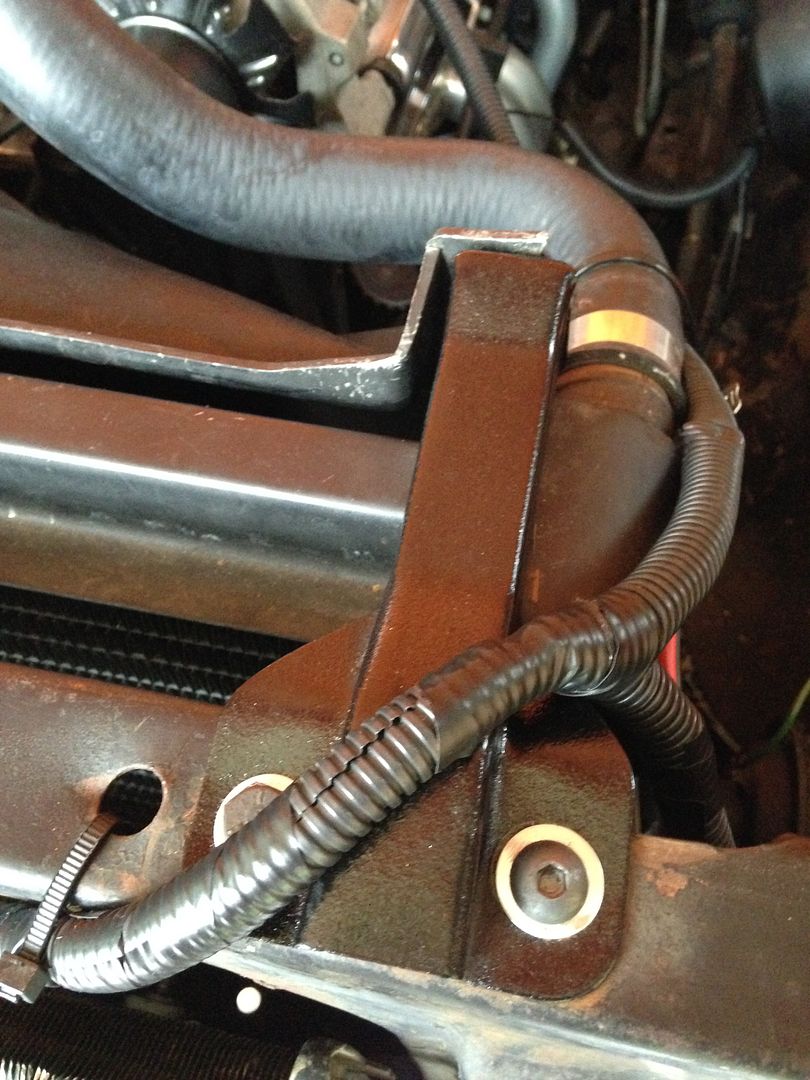

The original radiator mounting brackets looked as though someone had beaten them into submission with a hammer. I wound up repainting the used replacements I got with the shroud but was short a couple bolts so had to settle for some allen screws for now.

Finally, here's another shot of the bottom of the fan shroud to show the C-shaped slot from the front. In case you missed it, note the huge hole in the front cross brace that some moron cut with a torch to fit a couple of small transmission oil cooler lines. Eventually I will replace the whole crossmember but I'm amazed at how stupid some people are.

While I'm at it, here's a shot showing where the right frame was cut in order to clear an exhaust header. Thankfully this was confined to the right side and can be easily fixed but this kind of thing seems to be all too common to old vehicles. Thankfully this is about the worst of the damage and at this point you have seen nearly all the ugly warts this old Beast has.

In the end, this was a good modification as it keeps the engine much cooler at idle, typically around 180ºF. Before, it would easily reach 200ºF if I let it sit for too long. The fan also kicks on and off at or near the purported temperatures judging by the water temperature gauge. I wired it to the ignition switch so it only runs when the key is on. For giggles one time I stopped the engine but left the ignition on and found it ran for 6-7 minutes before it shut off. Once I get the air conditioning working again my plan is to override the temperature sensor so that the fan runs whenever the A/C is on so stay tuned..