The next couple of posts will seem more of a lessons learned than progress of any sort.. Back in my youth many decades ago I was witness to what occurs when one of your siblings was too big for her britches and back talked my father. A quick back hand and she didn't do that again. From that day on, I have been a firm believer in learning from other's mistakes, so hold on and enjoy the ride. It isn't too painful..

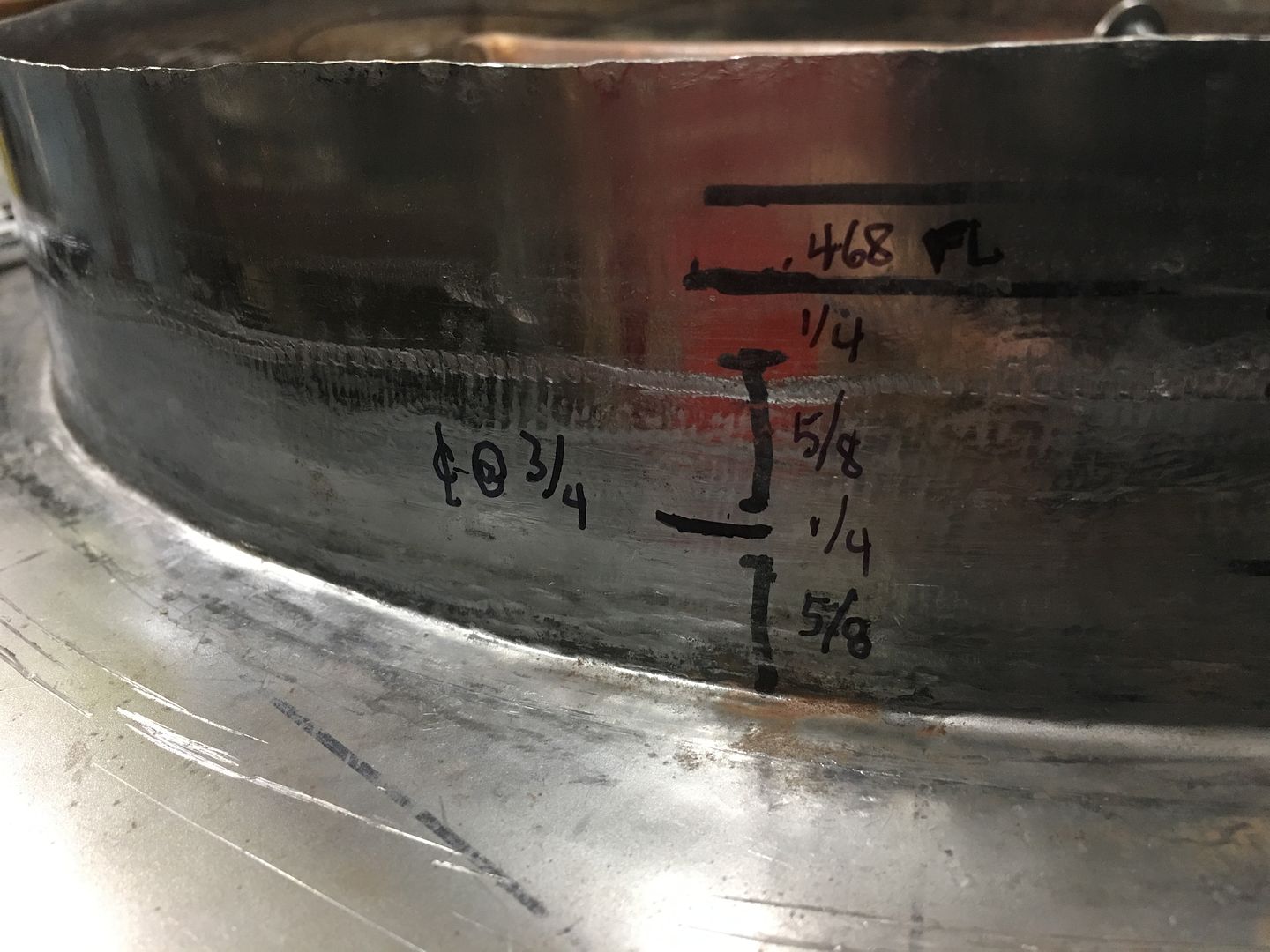

With the fan shroud formed it was time for a bead from the bead roller, and we planned on a wired edge to add strength, concentricity, and improve the looks. From dimensions taken from the rear flange of the core support (our fan shroud mounting location) to the center of the fan worked out to about 1-3/4". So given that height, these are the dimensions we came up with for our beadwork.. Typical wrap for the wire edge is 2.5X the diameter of the wire, so given 3/16 wire our flange for wrapping should be .468 or thereabouts..

The bead roller die that matches our wire edge size was not correctly dimensioned to be able to use as a backstop, so some "filler" in the form of rare earth magnets gave us the dimension we were looking for..

So using the bead roller and the joggle dies from the Biederman hood sides, the bead/wire edge was added to our test sample.

That looked about spot on, so the bead roller was used to add the center bead on the fan shroud, and the edge was cut to size and tipped to a 90* angle..

Now to use our joggle dies to add the outer bead detail.... which looks like the shroud mounting flange is in the way.. Did I say one piece fabrication was harder?

So a new die is in order, for the bottom we have a sliding lower toolholder so that will accommodate most of the offset there. for the top, we need to stack some dies to get the offset needed.

The upper die also needed a 45* relief on the bottom for installing the lower die.

Looks much better...

Our speed run...

https://www.youtube.com/watch?v=nyylI6tybew

.....and this happens on the last pass..