Wow, what a frustrating day! When I first started working on the wiper design back in April, I figured the twist in my design was too thin of steel on my bracket. When I had my friend cut it out for me, I had him make it the way I originally designed and make it without the side reliefs to bolt a possible brace to. Well I had to go with the latter! I bolted up the one in the upper pics and it put just enough twist (those little motors are really torquey!) that I realized that heavier bracket wasn't going to work either. Thank goodness I'd had him make the other bracket too.

So I bolted it up and used an existing hole in the cowl vent lever brace with a piece of 1/2" steel.

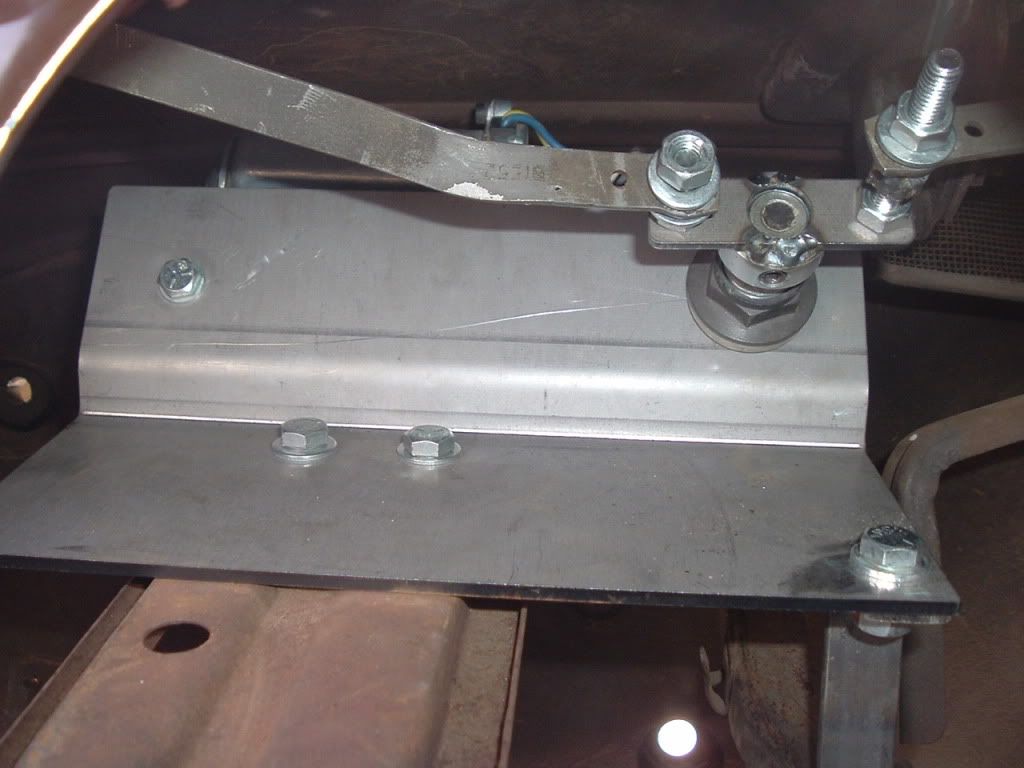

Here it is bolted up.

Don't laugh at the bolt length on the pivot link, I had to figure out how to get the pass. side to not hit cowl vent (notice hinge in background)! I'm so frustrated with how much slack/movement is in the original system and how tough it is to make them be perfect! You could just bolt it on and make it close, but I don't want close I want dead nut! I need to measure the bolt length and make that right and double check everything again! Sheesh