More travel for the day job, had to install a 24' video wall. Back in the shop finally, progress on the air cleaner continues.. We had some stainless mesh left over from our speaker grill fabrication that we plan on using to address air flow inside our pocket for the ignition coil.

An 1-1/2" Rotacut is used to provide the hole in the pocket, two pilot holes spaced 1/2" apart will expand the hole for us.. The venturi effect inside the breather should promote air flow across the coil.

Next, to hold the mesh in place some retaining rings will be needed. We'll use some MDF trimmed to size to fabricate these...

Or the action version....

https://www.youtube.com/watch?v=y9xRENMU9l8

The newly formed part has a tight hold on the hammer form, so much that we can clamp it in the vise, drill the two pilot holes to match the pocket, and drill out two 1-1/2" Rotacut holes without the part budging..

https://www.youtube.com/watch?v=wVM_iv-XZdw

The dynabride belt sander cleans up the points into flats, the side flanges are trimmed to size with a roloc sander, and then we can roll to fit the inside of the pocket.

https://www.youtube.com/watch?v=OyHC0p9NKrE

test fit....

https://www.youtube.com/watch?v=7DxT-oGXcfk

Holes are added for some 3/32 rivets to clear the mesh

Aluminum pop rivets are used to get a better view of the final look before we blow it apart for priming..

.JPG) https://www.youtube.com/watch?v=Z9-Hp-O925M

https://www.youtube.com/watch?v=Z9-Hp-O925M

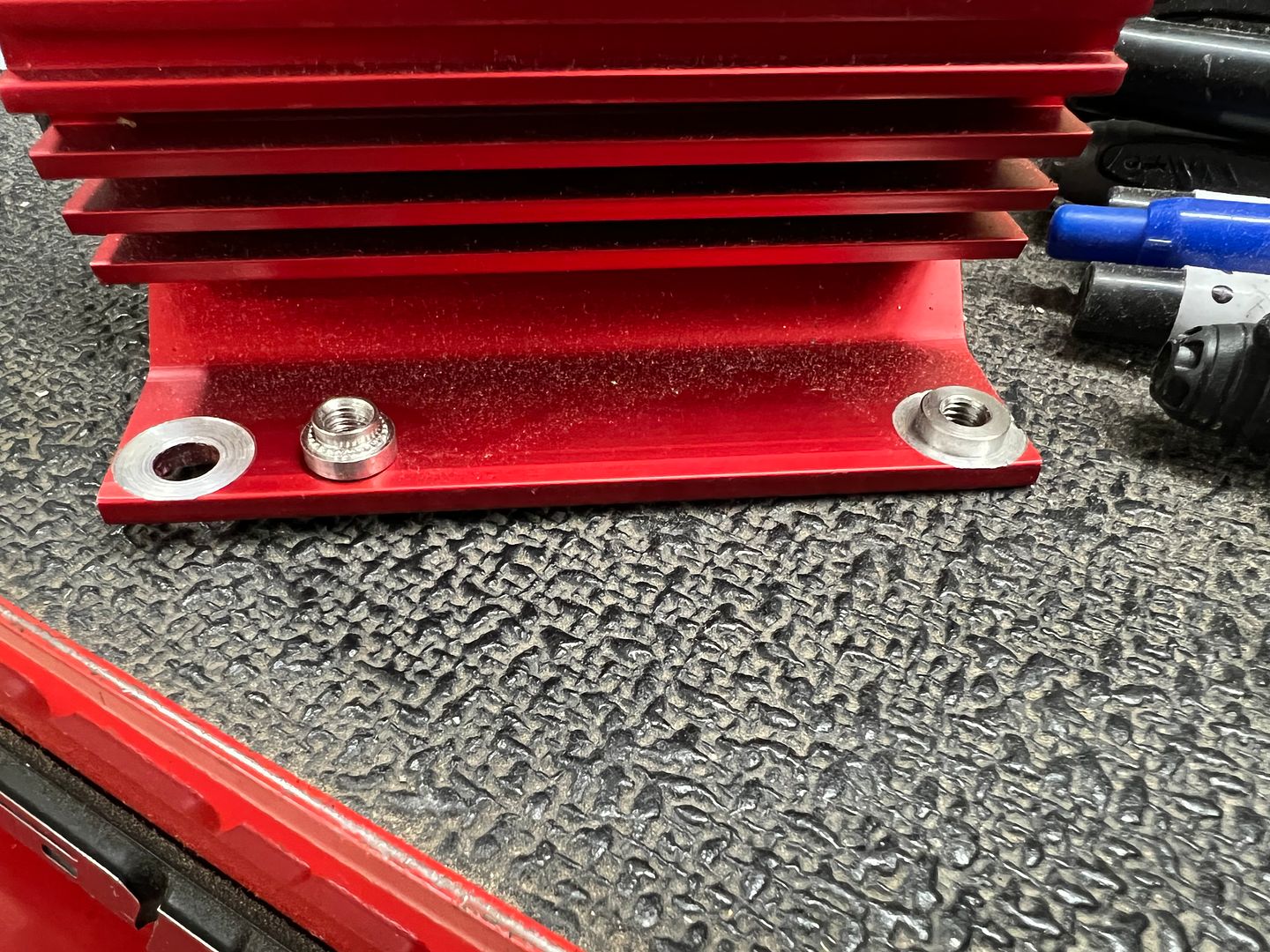

We will be using press nuts in the coil to ease the pain of assembly, and we also added some more shiny stuff on the front end..