|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,868

|

How To Fix Uneven Panel Gaps

Uneven panel gaps drive me crazy, so I found a way to fix them. You'll need 1/8" steel welding rods, welder's magnets, a grinder, a welder, and a DA sander. A long, flexible straight edge will be helpful also.

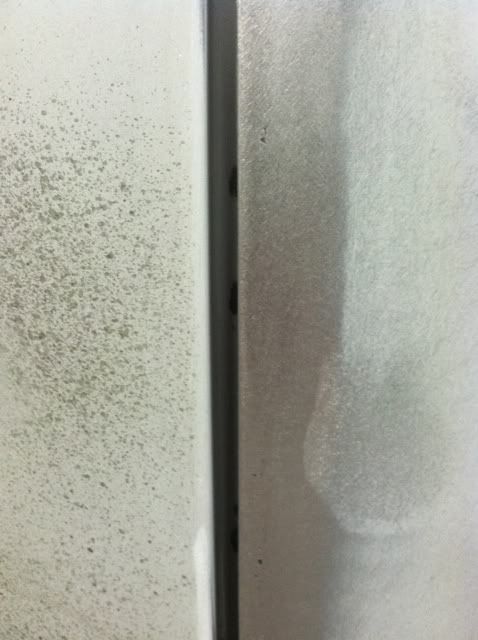

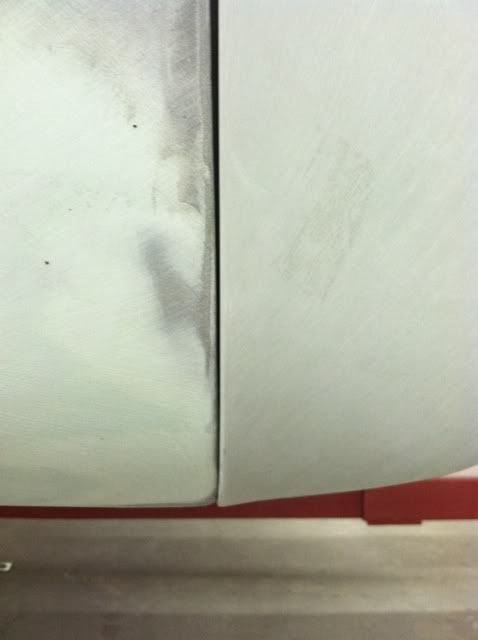

Once you have the door or panel adjusted so that the body lines are lined up and the panel is flush with the surrounding panels, take a look at the gaps and figure out how big of a gap you want between the panels. You can get carried away with this, make a feeler gauge to check and make every gap dead even, or you can just even out the worst areas. Here's what I'm starting with. On this truck, I'll just be straightening out the worst areas as the owner doesn't want a full on show truck. The gap under the body line is a good bit larger than it is around the rest of the door.   To start, bend the 1/8" welding rod to the shape of the door/panel edge and use magnets to hold the rod flush with the edge of the panel. Tack weld around the magnets to hold the rod in place. You can fine tune the shape of the rod to the edge of the door before you fully weld the rod on.   Once the rod is tacked in placs you can fully weld it on. I like to do one spot weld at a time, skipping around to limit heat build up until all of the gaps are filled in.    After fully welding the seam, grind the welds down flush with the door skin. I like to use a 4.5" grinder to knock down the biggest part of the weld bead, then switch to a 2" air grinder to finish off the weld.    There will be smaller uneven spots that won't need 1/8" rod. Just weld up the edge enough to close the gap.    Some areas will have a gap that is too small. For this you can't just grind the edge down because the edge will split. Grind it, then you'll have to weld the edge after grinding it down, and then grind the welds down to even out the gap again. Once you have the gaps even, take your DA sander and round over the edges of the areas you reworked so the edge will be rounded and smooth. Try to match the radius of the original edges the best you can.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

| Bookmarks |

|

|