|

|

|

#1 |

|

Registered User

Join Date: Feb 2015

Location: Houston, Tx

Posts: 3

|

TBI Swap Help Needed

Hello forum members, Iím having a problem with an efi swap that I did and I need your help to solve this problem. Iím going to list everything that I have done from the beginning so bear with me. This is going to be one heck of a read.

I swapped a 1991 C2500 350 tbi fuel injection system to a 1986 C10. This is not on my truck, I did this on my friends 1986 C10 and he wants his truck running properly again. We have been fighting this on and off for about 6 weeks. Details of the swap: Bought a 1991 C2500 700r4 auto work truck from a buddy, the truck was rusted beyond repair but the motor and trans worked. Odometer stopped working at 300k miles. Drove truck home and it ran fine and shifted fine. We did a few burnouts and general goofing off before pulling the motor. I pulled the motor and put it on a home built test stand. I then removed all the wiring from the truck, yes really, ALL THE WIRING. This was done so the truck could be hauled off and I would have everything I needed for the fuel injection. Hereís the link I used as my bible for removing excess wiring and overall conversion. http://www.truckforum.org/forums/che...rowd-diff.html I cut away all excess wiring and eventually got it narrowed down to just a few wires Constant power for the computer: I used the original fuseable link that was in the 91 Ground: all the grounds were tied into 1 main ground that is on the thermostat housing Switched power: 1 wire to turn on the computer that activates the fuel pump Starter crank signal: This wire goes to the solenoid on the starter to tell the computer that youíre trying to start the engine. Coil power: The white wire from the ignition coil goes to a switched ignition source Ac signal wire: tells the computer to bump up the idle when the ac is turned on These are just the loose wires, all the other wires go to their appropriate sensors. I shouldn't have to say that but I did anyway. Also checked continuity from each terminal from the computer connector to its appropriate location, I did this 3 times. After the wire diet I put the harness on the test motor from the truck that is on the test stand. I put the gas tank from the truck next to the engine and ran some fuel lines to the throttle body. Lo and behold the motor fired right up. Noisy as hell because all I have on there for an exhaust is the downpipe from the truck. The motor ran great with my modified harness, it would go into closed loop and idle perfectly. Now that I had a complete fuel injection harness I needed to do a few other things for it to work on the 1986 C10. The motor in the truck is not original, the PO had put in a 1980-85 4 bolt main 350 block casting number 14010207. This means that the intake from the 91 would not be a direct swap so instead of swapping intakes a simple adapter plate was made from ľ inch thick aluminum plate. I designed it so that the bores of the throttle body were over top the larger rear bores of the Q-jet iron intake on the 86. I also needed an inline fuel pump for the truck, I chose a Precision E16116 fuel pump rated for 9-22 psi. The o2 sensor needed to be mounted as well, a weld in o2 bung was purchased and welded in right after the exhaust manifold. THE SWAP: I took my time and did it right, totaled about 5 days of work from the time the truck drove into the garage to the time it was all put back together. I wonít go into the details of doing all that work. The only thing that we could not transfer was the Egr valve. It would not work on the iron intake so we just put a block off plate over the hole for now. This should not affect how it runs. THE PROBLEMS: Initially, it ran fine. However once it went into closed loop the idle began to surge from 900-1600 rpm. It also did not want to accelerate at all and seemed to be lacking power overall. During heavy acceleration the motor seemed to just Ďfall on its faceí. A severe lack of power was present. We soon determined that 1 problem was a vacuum leak at the throttle body, specifically the lower gasket that was for the Q-jet iron intake. One was purchased and aviation permatex was used to ensure that it didn't leak again. The next problem was the knock sensor, the esc module from the 91 was for an automatic but we were running a knock sensor for a manual trans. After some research I found out that it does make a difference. We put the knock sensor for the automatic on and the motor ran much better when accelerating. Exhaust leak at collector gasket, replaced both donut gaskets and put copper coat on them to ensure they didnít leak again. This could have been throwing the O2 sensor off. The idle was still surging from about 700-1100 rpm so we thought that it could still be a vacuum leak. While revving the motor in neutral and looking at the intake we could see exhaust leaking out of the intake at the mating surface between the head and intake. This is where the crossover port is on the intake. We figured that if its leaking there it must also be leaking vacuum. I sprayed carb cleaner all around the intake but I could not hear any change in idle. We replaced the intake gaskets anyway. The intake was milled flat and .125 inch thick gaskets were used. After the intake gaskets were replaced a new problem developed. Once the motor would warm up and go into closed loop it would still surge at idle but this time from about 500-800 rpm and would occasionally die at idle. It did not die at idle before, only after the intake gaskets were changed did this problem pop up. I think that the vacuum leak is solved but now the unsolved issue is causing the engine to die. After the intake was changed and it still had problems I broke out the big guns and downloaded winALDL and made a connector to go from the ObdI port to the serial port on my laptop. WinALDL is a computer software program that allows you to monitor what the engine is doing while running. You can also datalog and keep the information for later however I have not figured this feature out yet. I thought this would be the solution and point out what the problem is but it just provides raw data that you have to determine if its good or bad. winALDL info link http://winaldl.joby.se/aldlscreen.htm CURRENT PROBLEMS 2-11-15 : Runs very rich when in open loop, Idle surging and dieing when in closed loop, severe lack of power under acceleration. Well that is the story so far, a not so happy ending for a supposedly simple fuel injection swap. Hereís all the data that I have collected Computer number : 1227747 Tps voltage at idle: .69 volts , within spec. Fuel pressure: 40 psi, this is the pressure before the regulator. I have not found a way to check the pressure after the regulator. Iím not sure why a fuel pump rated for 9-22 psi is putting out 40 but thats what the gauge in the kit said. Rebuilt throttle body with BWD 10912 tbi kit. All gaskets and regulator components replaced. Code 24: VSS code. I eliminated the Vss so it will always have this code. It will not affect how it runs. No other codes currently Timing set at EXACTLY 0 degrees with the bypass connector unplugged. No loose hoses to cause vacuum leaks MAP sensor vacuum hose connects at back of throttle body like it originally did We have replaced all these components with good BWD units purchased at O'reilly Auto Parts. Coolant temp, TPS, MAP, O2 sensor, ignition module, oil pressure, ignition coil, IAC motor, knock sensor. The only original components are the following: Distributor and pickup coil, Esc module, egr solenoid, throttle body and injectors, computer. Please read through this all and comment as to what your ideas as to what the problem could be. If you need specific data just ask and Iíll see if I can get it for you. Iím going to college in San Marcos and the truck is in Houston so Iíll have to contact the owner and see if I can get the data. Sorry for the super long post but I wanted to be as thorough as possible so that you have all the info. Thanks, Ranger |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Dec 2007

Location: Kimberley, BC, Canada

Posts: 799

|

Re: TBI Swap Help Needed

Hi Ranger,

Thanks for the great explanation of all that you're already done. (instead of "it don't work"). You also seem to have a pretty good handle on all the typical issues that come up with this sort of thing. Have you verified that 40 psi fuel pressure is correct for the 91 engine? The TBIs I've worked on were more like 12 psi, but I believe some of the later ones used higher pressure. Just something to consider. What about the wiring to the IAC valve, or the IAC valve itself? There are 4 wires to control the stepper motor. I wonder if there's a problem there, leading to the idle surging. And what did you do with the AC signal wire? If it's left floating, the ECU could be intermittently seeing "AC on" followed by "AC off" and adjusting the idle RPM. Anyway, an interesting problem for sure.

__________________

Greg 64 GMC Suburban - 283, NV3500, 14 bolt 77 C10 swb - 292, SM465, 12 bolt |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Feb 2015

Location: Houston, Tx

Posts: 3

|

Re: TBI Swap Help Needed

Thanks for the ideas and suggestions. As to your comments-

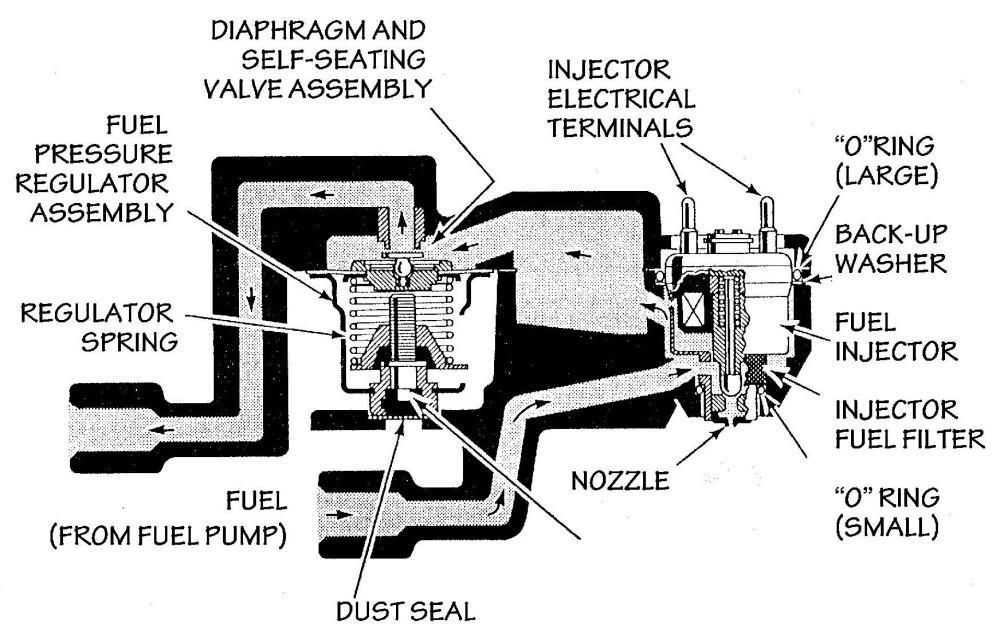

The IAC is working correctly, I verified the wires are going to their proper location in the computer connector. I have also checked that the IAC 'clicks' when the ignition is turned on. The a/c wire for the computer is spliced into the wire going to turn on the a/c compressor. I have verified on the winaldl program that it works and there is a noticeable change in idle when the a/c is turned on. I am on a couple different forums and have figured out the issue. WAY too much fuel pressure. Here's a diagram of the fuel flow for a gm throttle body  The regulator regulates the amount fuel being bypassed after it reaches the injectors. I did not know that. This means whatever the pressure is on the feed line is what the injectors are getting. Based on my previous fuel pressure check that means that the pressure going to injectors is about 40 psi. WAY too much pressure. Roughly 3x the amount it should be getting. Furthermore my research revealed that the fuel pump I am using is fine for this application and is not just blowing by the regulator. I have found multiple people on various forums that have used a similar pump with no problems. That leaves only 2 possible causes as to why its getting too much pressure: Faulty regulator or restriction on the return line. The regulator is brand new so I'm leaning toward the restriction somewhere along the return line. The reason I'm saying this is because I accidentally tested the fuel pressure with the return line off the throttle body. Fuel was sprayed all over the intake and it made a big mess but I seem to remember getting a pressure reading of about 10-12 psi, right where it should be. |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Dec 2007

Location: Kimberley, BC, Canada

Posts: 799

|

Re: TBI Swap Help Needed

Good stuff! You could just dump the return line into a 5 gallon jerry can for testing. Maybe the return line is kinked somewhere.

__________________

Greg 64 GMC Suburban - 283, NV3500, 14 bolt 77 C10 swb - 292, SM465, 12 bolt |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Oct 2010

Location: Ocean Springs, MS

Posts: 1,746

|

Re: TBI Swap Help Needed

Nice work figuring all that out. Can you tell me where you got the fuel pump? I am interested in doing something similar.

__________________

Gary 1971 Chevrolet C/10 1951 GMC 100 1977 GMC C15 1955 Chevrolet 3100 |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Feb 2015

Location: Houston, Tx

Posts: 3

|

Re: TBI Swap Help Needed

UPDATE: The owner of the truck disconnected the return line and run it to a 5 gallon gas can. Truck runs great now! Problem solved. Sorta... its still dieing at idle but I believe that to be because there is a procedure to set the IAC valve on these tbi systems. The current idle is about 400 rpm which is why its dieing (too low) . Also figured out the restriction on the return (see below). Other than the idle issue the owner of the truck says it runs great and there is no more idle surging. Have yet to test acceleration due to only being able to run it while not moving because of the return line just dumping into a jerry can.

The fuel pump I used for the swap is a Precision fuel pump part number E16116 that was purchased at O'Reilly Auto parts its not a cheap pump ($112) but you don't really want to be cheap when it comes to a fuel pump. It's a universal Tbi fuel pump. I looked up the sending unit that is on this truck and saw something interesting.  If you look at the picture the tube on the left is the pickup tube and goes to the fuel strainer, the tube on the far right is a small 1/4" tube that ran to the original mechanical fuel pump as a vent or something. The line we used for the return line is the one in the middle. What is that thing that is on the end of the line middle? That line is 5/16" and originally ran to the charcoal canister for a vent. I'm guessing the thing on the end of that tube is a check valve or some sort of restriction. At any rate, its whats been causing the problem all this time. I'm going to drive to Houston next weekend and will fix the problem with the sending unit. After that its just a matter of setting the idle and a few minor things and it will be done. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Oct 2014

Location: Tacoma, WA

Posts: 106

|

Re: TBI Swap Help Needed

Left is the pickup line

Center is the vent line Right is the over pressure return line

__________________

84 K30 CC LB Fleet side 454/400/205/14 bolt Rebuilt 2200 miles 91 K15 Z71 SB 350/700r/241c/12 bolt 372k miles 96 K15 Sub 350/4L60/243c/10 bolt 333k miles |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Oct 2010

Location: Ocean Springs, MS

Posts: 1,746

|

Re: TBI Swap Help Needed

I have seen that before, when I did a TPI conversion on an old car I used the 5/16 return line on the sending unit. Fortunately, I pulled the tank to inspect everything before I hooked it up. I found the 5/16 port had a metal cap stamped into it on the inside with only a tiny hole in it! Apparently, they put some sort of restriction on this line to keep liquid fuel out of it.

__________________

Gary 1971 Chevrolet C/10 1951 GMC 100 1977 GMC C15 1955 Chevrolet 3100 |

|

|

|

|

| Bookmarks |

|

|