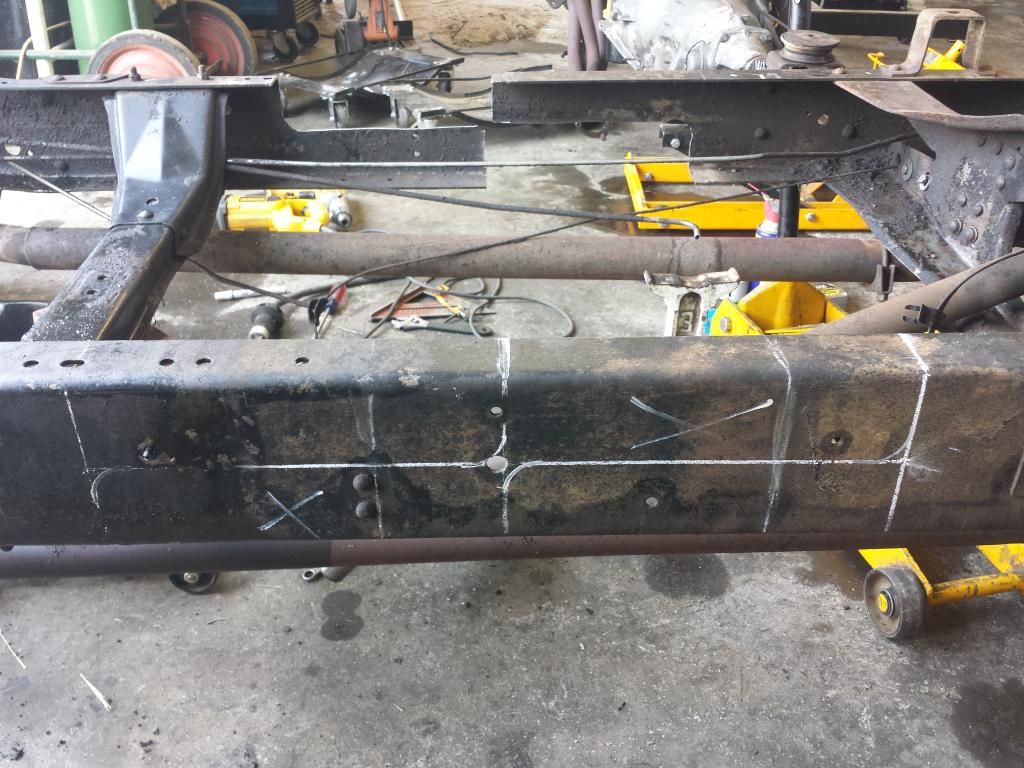

Thursday I laid out the cuts for the shortbed conversion.

I measured 4" forward from the front rivet of the rear cab mount. That's where I made my 1st line. I then measured 12" forward and made my 2nd line. then I measured 12" forward from the 2nd line to make my 3rd line.

I then measured 3" down from the top of the frame rail,(since it is a 6" tall rail) and made marks about every 6" and connected them with a straight edge.

I then used a Teflon tape roll to radius the corners of the cuts (learned that from Stacy David's Gearz), and marked out the pieces that I was going to cut out.

Next I took the Teflon tape roll over to my hole saw kit and found a hole saw that matched the outer diameter. (in my case I believe it was a 2")

Note: you could always use the hole saw of your choice to mark the radius cuts in the corners. I cut out my radius cuts first by removing the pilot bit from my hole saw, lining it up with the lines, and sliding a small punch down the pilot bit hole to make a centered mark.

then I simply cut out the rest with a sawzall. I made my cuts flipped from each other to increase strength, but it makes it harder to line up.