|

|

|

#551 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Ok lets take it step by step. 1) Take a look at a circuit attached. The RV section is top of the page. The only major difference between the two is that RV has prime terminal hanging at the end of red wire (under FP relay) and CK have that end terminated at ALDL connector. Otherwise functionally and electrically they are the same. 2) Theory of operation. Re-install FP relay. Disconnect oil pressure switch connector. At the oil pressure switch locate orange wire terminal - it must have 12 volts at all times. The fuel pump side may have either tan/white or gray color wire - this is a switched side of FP relay. During POST ECM applies 12 volts at Pin A1 (dark green/wht) energizing FP relay for about 2 seconds. Also at the same time it monitors voltage on pin B2 (Fuel pump signal). FP power-up FP circuit for about 2 seconds and shuts off. This is a normal operation without fuel module. When you removed FP relay ECM will not see 12 volts pin B2 (Fuel pump signal) which will set DTC 54 (FP voltage low). With DTC 54 set ECM goes into limp mode and depending on calibration it may not apply control signal (A1) during cranking - I simply do not know why, but I have seen this before. What is important is that ECM is able to supply +12 volts to FP relay from pin A1 dark green/wht wire. Now, with FP relay re-installed connect DVM to measure DC voltage from gray pin of the oil pressure connector to ground. Oil pressure switch is a fail safe mechanism if FP relay fails with engine running. With ign off you should see 0 Vdc, ign into run - you should see 2 sec (with Fuel module disconnected) or 20+ seconds with fuel module connected. During cranking there must be +12 volts. 3) dark green/wht is a low current switched source - supplied by ECM (pin A1). It should not be shorted to ground as it will blow switching transistor inside ECM! Use DVM - do not use test light since you do not know how much current your test light is pulling. Typical FP relay has a coil resistance between 200 and 300 Ohms and pulls less than 100 mA of current from 12V. 4) Take a look at FP test connector (490 red on attached schematic). It is connected to NC contact of FP relay. Under normal conditions, FP relay is powered moving center contact from NC to NO position and with engine running you should 0 volts. If and only if FP relay failed to close and engine is running you will see +12 volts as fuel module or oil pressure switch are supplying power to FP. This way you can establish if you have a flaky FP relay coil or control circuit. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#552 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

If you made it 6" in diameter the 3" tall sump could hold a little over a 1/3 of a gallon of fuel. That should be enough for a pretty heavy turn while low on gas. Start with a solid ring and drill a couple 1/4" holes around the perimeter to allow low fuel level sharing with the rest of the tank but not bleed off too quick and defeat the purpose of the sump in the first place. If you could hard line plumb the return line from the regulator into the side of the sump ring it would almost always have fuel in it.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#553 |

|

Registered User

Join Date: Oct 2006

Location: Southern Kalifornia

Posts: 3,066

|

Re: Tbi swap build thread

I just re-read my last post, sorry, I did not mean I grounded the dark green/white wire. I was using the DVM. Black lead to battery ground and red lead to pin A1.

I will go test the oil pressure switch now. But everything I have done thus far, the voltage never shuts off after 2-3 seconds,fuel module connected or not. That is where I am confused. I am going right now to test the oil switch. Thank You BTW should I start my own thread? I feel bad for hijacking this one.

__________________

------------------------------------------------------ -Lance 2000 Chevy C2500, 5.7, 4L80e 1999 Suburban K2500, 7.4, 4L80e 1980 Camaro..son's car...PROJECT |

|

|

|

|

|

#554 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Regarding a thread - your choice. This thread is a collection of problems and solutions relating to swapping TBI system into early squire body trucks. For conversion I look for 87+ trucks and cars for parts. I never visit 88+ forum since my rig is 1975. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#555 |

|

Registered User

Join Date: Oct 2006

Location: Southern Kalifornia

Posts: 3,066

|

Re: Tbi swap build thread

OK here are my findings again.

Fuel module connected: oil pressure switch; key off(tan/white didnt have a gray) 0dcv, key on 9.36 dcv for 20sec, cranking 0dcv Fuel module disconnected; oil pressure switch; key off 0dcv,key on 0dcv,cranking 0dcv Engine running;fuel module connected; fuel pump test pig tail 12+dcv(actually 13.8dcv)

__________________

------------------------------------------------------ -Lance 2000 Chevy C2500, 5.7, 4L80e 1999 Suburban K2500, 7.4, 4L80e 1980 Camaro..son's car...PROJECT |

|

|

|

|

|

#556 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Sanity check - did you check all your fuses on your main fuse panel (IFIK as I do not have FSM in front of me that there are couple of fuses related to EFI)??? Fuel module is providing back up power to fuel pump during POST. Once it is removed no 12V power reaches FP. Conclusion BAD FP RELAY or FP socket since you have verified that 12 volts is supplied by ECM to the FP socket contacts between dark green/wht and black/wht wires during POST. Measure relay coil resistance - it should be between 70 to 300 Ohms (depending on OE manufacturer) pins 85 and 86 Can you take a photo of your FP relay??? //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#557 |

|

Registered User

Join Date: Jul 2010

Location: Colorado Springs, Colorado

Posts: 19

|

Re: Tbi swap build thread

I just thought of something that I haven't seen much mention of (if any) on this thread.

If you are installing TBI with the idea that your truck should keep running at high angles, you should consider making sure that your system will shut off in a roll-over. With a fuel surge tank system installed, like an am doing, there is every possibility that there will be enough fuel in the surge tank to keep it running upside down! My solution is to install a mercury switch that cuts power to the TBI system if I reach an angle of more than 90 degrees. My TBI ignition system is powered by a single HD relay, so I will just put it between the ignition source and the relay. I'll have to experiment to make sure that a hard bump or bounce doesn't cause the TBI to turn off. available from Parts Express - http://www.parts-express.com/pe/show...number=060-275 Lets hear it if you have other ideas. Keith Last edited by kcblazer75; 08-23-2010 at 03:13 PM. |

|

|

|

|

|

#558 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

http://www.summitracing.com/parts/ATM-3241/ http://www.summitracing.com/parts/REB-140-1345/ http://www.summitracing.com/parts/SMP-PS171/ Plenty of different pressure ranges out there to suit your specific engine. It just needs to be low enough that your cranking oil pressure will turn it off so the truck will start.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#559 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

Another is that they sometimes stick and need a tap to make them work. That would be bad if you were needing it to work to cut off the fuel flow.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#560 | |

|

Registered User

Join Date: Jul 2010

Location: Colorado Springs, Colorado

Posts: 19

|

Re: Tbi swap build thread

Quote:

That is a great idea. I like it better. A pressure switch is also a great safety in case you lose an oil pump, or lose your oil for some reason (bust the pan on a rock for example). That could save an engine. Question... This would mean that turning on the ignition would NOT power up the ECM. So ECM would go strait from OFF to start when I crank the motor since there's no pressure until the motor starts cranking. Does the ECM require any "boot up" time to set things up before being ready to start? I know I wouldn't get that 2 second fuel pump hit at ignition on. Is there any circuit that is ONLY hot when the engine is running, and not with just ignition on? I cant think of one. If I can find one, I could use that to allow power to the ECM when ignition is on, but not started. Thanks Keith |

|

|

|

|

|

|

#561 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

You would want it to only shut off the fuel pump relay after the engine started so the ECM pump 2-second prime feature works still and you could trouble shoot the system like normal. Maybe if you wired the ground for the oil pressure warning sensor through the park / neutral switch so it only functioned when the vehicle was in gear. This way the fuel pump could be controlled properly by the ECM until you put the truck in gear then the low oil pressure sensor controlled relay could shut the fuel pump off if the oil pressure was too low. This assumes if you are upside down or on your side that the truck was in gear to get you there.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#562 |

|

Registered User

Join Date: Nov 2009

Location: Parachute, CO

Posts: 183

|

Re: Tbi swap build thread

So I still haven't been able to get my rig to start on it's own.I can put a little gas in the TBI and it fires right up then the injectors fire and it will run all day.But once you shut it down and let it sit it won't fire without putting gas in the TBI again.

Do I need to have the fuel pump hook up to the relay?I have it wired to it's own switch and relay.That is separate from the ECM.

__________________

1984 1ton 4x4 crew cab dually 6.2 diesel,465,205,D60,D70,1987 3/4ton 4x4 suburban 5.7 FI350,TH400,208,1985 CJ-7 FI406,465,205,D60,FF14, 1970 Jeepster 350,465,205,D44,FF14, |

|

|

|

|

|

#563 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Lets solve your problem. What you are describing is a classic Fuel Pump Relay or FP relay control circuit failure - malfunction. Oil pressure switch contacts close once oil pressure builds above 4-6PSI and that powers-up FP and engine is supplied with fuel and all is good. 1) Did you verify that your FP come-up during POST for 2 seconds??? It should if FP relay is functioning. Couple of electrical checks you must perform: a) FP operates for about 2 seconds during POST. A POST is power on self test performed by ECM when IGN key is moved into run position. SES light goes from solid on - blinks off - back to solid on if all is good. ECM also power up fuel pump for about 2 to 3 seconds. b) ECM supplies +12 Volts to the FP relay socket on dark green wire (ECM pin A1) c) The black/white wire from FP socket is connected to a good ground. If you can go through above check list you'll most likely find the culprit. Let us know. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#564 |

|

Registered User

Join Date: Nov 2009

Location: Parachute, CO

Posts: 183

|

Re: Tbi swap build thread

I just got it figured out.I had the A-6 pin going to what I thought was a switched 12v source.Well it wasn't.I rewired it to a good 12v source and it fires up.Thanks for all your help.I may have more questions later.You never know.Again thanks.This thread is awesome!!

__________________

1984 1ton 4x4 crew cab dually 6.2 diesel,465,205,D60,D70,1987 3/4ton 4x4 suburban 5.7 FI350,TH400,208,1985 CJ-7 FI406,465,205,D60,FF14, 1970 Jeepster 350,465,205,D44,FF14, |

|

|

|

|

|

#565 | |

|

Registered User

Join Date: Jul 2010

Location: Colorado Springs, Colorado

Posts: 19

|

Re: Tbi swap build thread

Quote:

Thanks for the help! Keith |

|

|

|

|

|

|

#566 |

|

Registered User

Join Date: Oct 2009

Location: Summerset SD

Posts: 312

|

Re: Tbi swap build thread

|

|

|

|

|

|

#567 |

|

Registered User

Join Date: Jul 2010

Location: Colorado Springs, Colorado

Posts: 19

|

Re: Tbi swap build thread

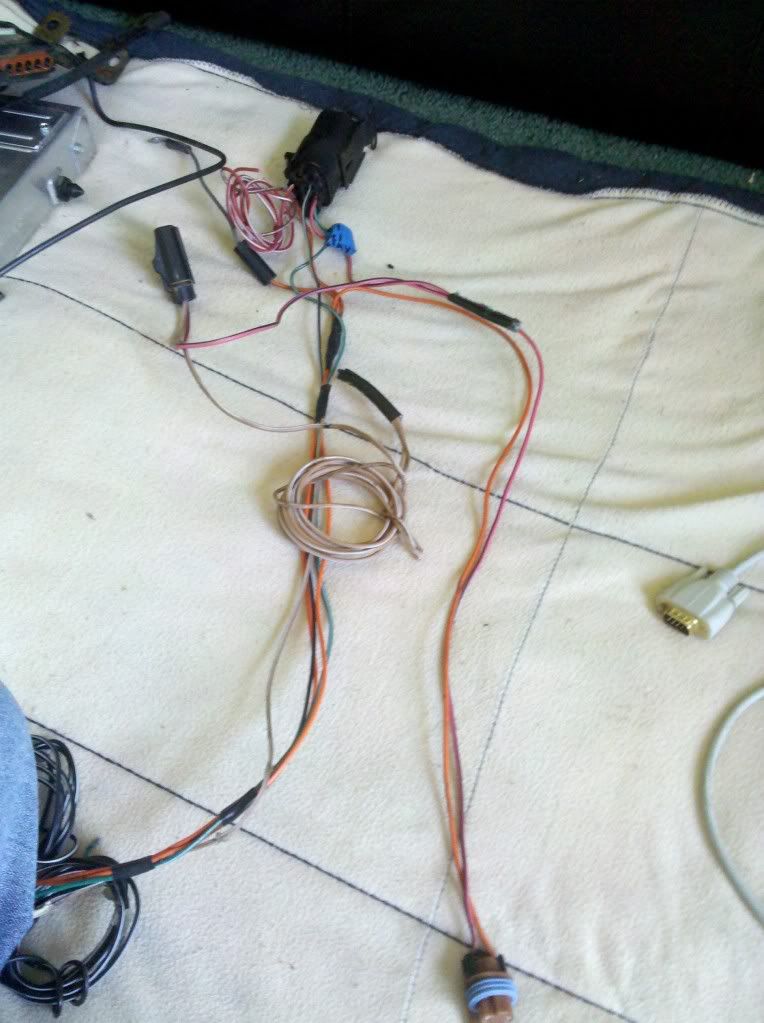

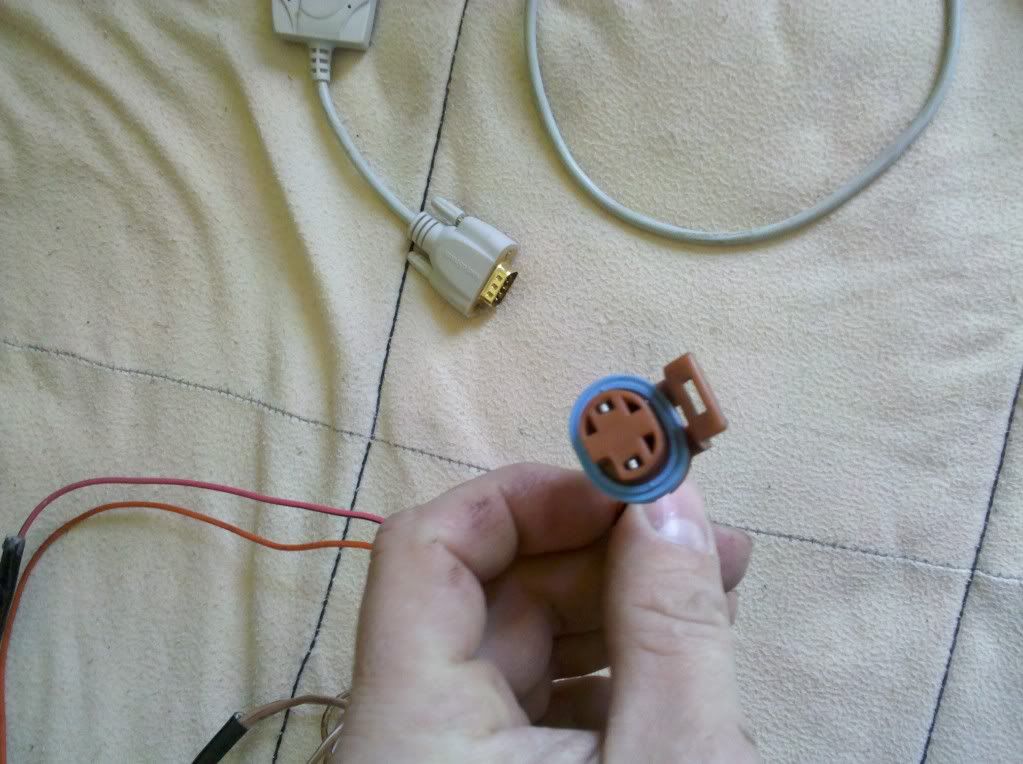

here is the updated diagram and pic of my surge tank.

Keith |

|

|

|

|

|

#568 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Keith

Very nice - it should work. My only concern is to protect fuel system components from damage - rocks, etc. BTW where did you source that tank - is it home brew?? //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#569 | |

|

Registered User

Join Date: Jul 2010

Location: Colorado Springs, Colorado

Posts: 19

|

Re: Tbi swap build thread

Quote:

I got really lucky with the tank. I found it on my dads property. It is a high pressure tank from a very old refrigerator. I only had to add one port. I cleaned it out and pressure tested it for two weeks at 90 psi before deciding to use it. Thanks again Keith |

|

|

|

|

|

|

#570 |

|

Registered User

Join Date: Jul 2010

Location: Colorado Springs, Colorado

Posts: 19

|

Re: Tbi swap build thread

Rollover/low oil pressure cut off

Here is a diagram of the circuit I am considering adding to my truck. The idea is to interrupt the ground to the fuel pump relay, effectively turning off the relay and the fuel pumps in the event of an abnormal loss of oil pressure. i.e. rollover or loss of oil. When in park or neutral, relay 2 provides ground. This is for starting and the 2 second FP burst at POST. When in drive, relay 1 provides ground. If there is a loss of oil pressure while in drive, ground is disconnected, and the fuel pumps turn off. The only concern I have is that I could not find the specs for the oil pressure switch I have. ( it is three wire, shaped like a roll of quarters ). Im worried it might shut the fuel pumps off at low idle. Feedback? Thanks Keith Picture removed 9/5. Last edited by kcblazer75; 09-06-2010 at 09:59 AM. |

|

|

|

|

|

#571 |

|

Getting Old; Going Broke

Join Date: Apr 2010

Location: Owasso OK

Posts: 2,764

|

Re: Tbi swap build thread

Not a TBI swap, but a TBI replace, need some guidance so thought I'd make a quick post for the gurus.

First, making sure this is the wire we undo to time it with. We have the replacement motor all hooked up, new Holley TBI, edelbrock TBI intake, all new sensors... it's all new. Runs good, then runs bad, runs good, then runs bad. I now know we did not time it correctly, since we did not undo any wire, so need to be certain this is it for an 87 R10, came factory with a 350TBI. The wire I'm seeing is a tan wire with a black stripe on it, just comes out of a loom, and goes back in, to the drivers side fender of the brake booster. And second, I'm really hoping I do not have to chip it or send it out for a tune, but I'm sure there is a strong chance of it. We replaced the engine with a GM 12499529 crate motor. Horsepower: 290 @ 5100 RPM Torque: 326 ft/lbs @ 3750 RPM Max Rec. RPM: 5100 RPM Compression Ratio: 8.5:1 Heads: Cast Iron 76 cc Chamber - 1.94 Intake valve/1.5 Exhaust valve Camshaft Lift: .450 Intake /.460 Exhaust Flat Tappet Duration @ .050" (222°Int/222° Exh) Lifters: Flat Tappet Connecting Rods: Powdered Metal Block: 4-bolt main Pistons & Pins: Aluminum Crankshaft: Cast Iron Nodular, 3.480" Stroke Rocker Arm: 1.5 Ignition Timing: 34° BTDC total advance Edelbrock 3704 TBI Intake Manifold Holley 502-6 Throttle body Just in case anything matters, which I know it will.

__________________

Why is every used 350 sbc out of a corvette? There's only two things that excite a man, expensive toys and real expensive toys. VEGETARIAN: That's an old Indian word meaning "I don't hunt so good." When the going gets tough, switch to power tools. Last edited by RandyP; 08-30-2010 at 10:12 AM. |

|

|

|

|

|

#572 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

1) The single pin connector is used to set base timing (EST bypassed). For stock C/K trucks it is 0 deg, F bodies with TBI it is 6 deg. There is a detailed step by step procedure how to set base timing. 2) The 290HP crate motor is a poor choice for a stock TBI system (or Holley equipped for that matter). The problem lies with cam that GM chose for that crate engine having 222/222 deg (0.050) duration. It is nice rumbling cam for carb equipped rod, but it is poor choice for a truck. The rest of the engine is great, but this cam used on the 68-81 L-46 and L-82 Corvettes does not create enough vacuum at idle for stock ECM calibration. You can try mail order chips (tbichips.com) service or swap in 'TBI friendly' camshaft better suited for truck duty. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#573 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Try to locate GM part number stamped on metal portion of the sensor body. Take a trip to a Chevy Dealer parts counter and see what his parts books have to say. From what I know - 4 to 6 PSI is a range, but there are exceptions as well. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#574 |

|

Registered User

Join Date: Nov 2010

Location: Ishpeming, MI

Posts: 36

|

Re: Tbi swap build thread

Ok 1st of all This thread

I have learn quite a bit a big thank you to all! I have learn quite a bit a big thank you to all!Just to let ya's know I have read this from pg1 to pg23 whew alot of  going on. going on.OK now on to the Q's . 1. Their is a link to a fuse block If if remember wright anyways the link is dead! 2.Ok I have the original ALDL plug out of the 88 pickup do I just route the wires required for this wright into this plug or is there something to go between IE fuses . 3. Even thoe I read through this front to back and followed the printout where do I hook the Injector power up along with the other power ? 4. I have the single (BIG) relay for the fuel and their is a pink/black wire that comes out of that and goes to a plug their is also a Orange wire and they are both connected to a plug I think this is the oil press plug am I wright.... Bottom look lets see g/w to com p/b to fuse and (plug no clue) b/w ground tie org to tie, What do I do with the red/white?    Here is a reference pic I was wondering if I could put the senor in the location in the red square? I have read many different things on the injectors and now confused can some one tell me witch ones these are?  Sorry for the size no clue on how to make them smaller. thanks for any info..... Last edited by Chad77; 11-13-2010 at 01:51 AM. Reason: needed to add |

|

|

|

|

|

#575 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

1) Few questions first - what are you working on, model, year, etc? Second, what is the year of TBI system that you are using? 88??? Regarding fuse link - you may want to take a snapshot of it and posted. There are several and things changed over the years. So the key to this is to identify what it is, how it works and is it really needed. 2)ALDL connector needs a handful of wires routed to ECM and ground: Pin A Ground (black/white or black) - make sure that it ties to ground and ECM A12 Pin B Diagnostic (white/black) ) Pin C can be omitted Pin D SES - (brown/white) very handy if your panel SES light is not working Pin E Serial data (orange) 3) Injectors need +12V power from IGN circuit - fuse box. The key is to find circuit that is hot when ignition is in RUN and CRANK. I use a BOSCH relay powered by IGN (purple wire that powers ignition coil) to provide separate circuit for injectors. You'll need 10 AMP fuse for circuit protection. ECM has two power circuits. Battery on B1 - use 10 AMP circuit and run to battery (always hot) circuit and the other is IGN On - Pin A6 (pink/black) also use 10 AMP inline fuse for circuit protection. You'll have to find circuit in your fuse box that is hot with ignition on and during cranking! 4) You are describing Fuel Pump relay (FP) FP relay socket should have orange wire - that goes to battery via fuse link, Gray wire - that wire provides switched power to FP in the gas tank (or inline). Pink Black wire on FP socket is used to prime or test fuel pump. The oil pressure switch usually has three wires: orange, gray and brown. Orange goes to battery, gray goes to FP and brown is used for dash light or gauge. FP socket should have two more wires: dark green and black-white. These are used by ECM to power FP relay. 5) Sure - take pictures. It makes everything easier. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

| Bookmarks |

|

|