|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: Mar 2015

Location: Tuttle, Ok

Posts: 4

|

Why not drill the fire wall for brake booster?

Greetings Gurus!

I have spent many hours reading about brake upgrades and am ready to whip in to O'Reilly's and buy a brake booster and dual master cylinder for my drum/drum 65 C10 economy restoration. Sounds like a 1970 C10 booster/master cylinder combo should work for drum/drum with no need for a proportioning valve or metering block. I'll just need to do a little plumbing. What is the big fascination with not drilling holes in the fire wall? I've read page after page about Cap'n Fab's bracket and extending the linkage, but why? is there a clearance issue that I'm not seeing? This doesn't look nearly as clean to me as a flush mount booster. Plus it costs money (which my wife apparently needs for groceries) and who is actually scared about drilling holes in these trucks? We do it all the time for everything else. What am I missing guys? Thanks in advance for the sage wisdom |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Apr 2012

Location: Wisconsin

Posts: 3,322

|

Re: Why not drill the fire wall for brake booster?

While I do like the Captains bracket and its top of the line quality ! It , to me is so simple and in my opinion , cleaner, to bolt it right to the firewall.The down side to drilling is from a restoration standpoint , leaves 4 drilled holes and some grinding inside the firewall. If you had a super nice low mile survivor type truck I would never do this! Only thing I dont like about the 67 72 boosters is the size and distance from the firewall and clutter with the brake lines. Heres several I did using 1965 1966 Impala brake boosters and these boosters look factory in shape and size.

__________________

IS IT an EATON or Chevrolet rear axle https://67-72chevytrucks.com/vboard/...d.php?t=843778 The hubcap thread http://67-72chevytrucks.com/vboard/s...d.php?t=702839 WANTED : 1963-1966 6 Cylinder Fan Shroud WANTED :1964-1966 PANEL TRUCK |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jul 2015

Location: Seattle

Posts: 228

|

Re: Why not drill the fire wall for brake booster?

i'm doing a '76 booster and MC (disc/drum) and am in the same boat about direct firewall mounting. After holding the booster in place and realizing how big it is I saw no way that I could add a bracket and push it farther out into the engine bay. I'll be using one of the original holes and drilling a couple more, but the linkage matches up almost perfectly. I also chopped off part of the bracket that didn't sit well with me visually. I should be mounting in the next few days after it's painted, i'll post more pics on my build thread (linked in my sig)

Keep us posted on your progress

__________________

1961 Chevy Apache "BoomStick" -First build, lots of plans, little experience. What's the worst that could happen? http://67-72chevytrucks.com/vboard/s...d.php?t=694506 |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Mar 2015

Location: Tuttle, Ok

Posts: 4

|

Re: Why not drill the fire wall for brake booster?

Outstanding! Yes, I wish I was starting with a low mile really desirable piece, but that is just not the case.

So, I see the cleanliness of the '65 Impala booster. That's obtainable enough, but that is another single reservoir master cylinder. Did you just play the "Match the Master Cylinder to the Booster" game in the parts store. I think the kids at the counter would get a kick out of that. It's probably just an intermediate shaft issue anyway, right? |

|

|

|

|

|

#5 | |

|

Registered User

Join Date: Apr 2012

Location: Wisconsin

Posts: 3,322

|

Re: Why not drill the fire wall for brake booster?

Quote:

Edit , I should also ad that I've let several guys and lady's drive my trucks that I've converted, they all loved how easy the trucks stopped. My wife has driven every truck I've owned, manual drums or otherwise, she likes these power brakes or disc brakes the best.

__________________

IS IT an EATON or Chevrolet rear axle https://67-72chevytrucks.com/vboard/...d.php?t=843778 The hubcap thread http://67-72chevytrucks.com/vboard/s...d.php?t=702839 WANTED : 1963-1966 6 Cylinder Fan Shroud WANTED :1964-1966 PANEL TRUCK |

|

|

|

|

|

|

#6 |

|

hillbilly

Join Date: Apr 2007

Location: hampton,tn

Posts: 459

|

Re: Why not drill the fire wall for brake booster?

Would a 73-87 booster/master cylinder combo work? I would rather do this but I will have to make a brace for the clutch master cylinder no matter what I do

__________________

-1962 C-10 |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Apr 2008

Location: Md

Posts: 2,451

|

Re: Why not drill the fire wall for brake booster?

I Think it depends on your skill, comfort level of making parts yourself. My 62 had a hydraulic clutch hole and MC hole. This goes back 25 years so before Al Gore invented the internet. I had a donor 83 front end, rebuilt the disc's brake front cross member, master cylinder and booster. Covered holes in the firewall with aluminum plate. Drilled holes for the booster bracket and made a new rod for the brake booster. There are some challenges getting this all correct and accurate. If your handy give it a shot. In the 2nd photo you may see elongated nut extending the booster rod.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=635605 |

|

|

|

|

|

#8 |

|

Never Ending Projects

Join Date: Jul 2006

Location: San Diego, CA

Posts: 3,836

|

Re: Why not drill the fire wall for brake booster?

So I assume everyone is drilling a 1" lower hole in the brake pedal, so you get the correct pedal ratio. If you hook a power booster to the factory non power brake pedal hole, you will get a low pedal and touchy brakes.

The later factory angled brackets were to angle the push rod down so it would not bind, when mounted 1" lower. They might be ugly but they served a purpose. This is also why I believe the original factory booster had a pivot linkage within the mounting bracket, to allow it to be mounted to the original mounting hole but have the correct pedal ratio. YMMV

__________________

. 1965 C10 Panel,  Tiki Express http://www.67-72chevytrucks.com/vboa...d.php?t=506580 SOLD Tiki Express http://www.67-72chevytrucks.com/vboa...d.php?t=506580 SOLD1968 Chevy C10, Long, Fleetside, Hot Rod Hauler http://67-72chevytrucks.com/vboard/s...d.php?t=313233 SOLD 1965 Chevy C10, Long, Fleetside, Hot Rod C10 http://67-72chevytrucks.com/vboard/s...d.php?t=415702 SOLD We were given two ears and one mouth for a reason... listen twice as much and speak half as often... |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Nov 2008

Location: kannapolis, nc

Posts: 508

|

Re: Why not drill the fire wall for brake booster?

I used a 84 k10 booster

__________________

2000 c3500 utility bed 7.4l 5sp manual old body style. Cab and chassis 1964 GMC K10 1965 Chevy C50 |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Mar 2014

Location: Cambridge, Ontario

Posts: 507

|

Re: Why not drill the fire wall for brake booster?

Hi ianwcox,

Here's how I flush-mounted a small CPP booster in my '63. I made a template out of aluminum to be able to see how big the new opening had to be. Due to the brace on the inside of the firewall, I shifted the opening toward the driver's side of the truck by about 3/16". I drilled some small holes to see exactly where they were breaking thru. Everything looked good, but the lower holes were partly on a rib on the firewall. I then drilled the holes to size. To cut away the rib to allow the mounting nuts to sit flat, I used a modified "backwards" 15/16" hole saw. I flipped the hole saw around backwards, stuck it thru the hole from the inside with the hand drill on the outside to cut away the rib at the hole locations. I hope the pics make sense...

__________________

* My 63 C10 SWB Fleetside (converted to BBW): http://67-72chevytrucks.com/vboard/s...58#post6851558 @johnny_lamebridge on Instagram

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Mar 2014

Location: Cambridge, Ontario

Posts: 507

|

Re: Why not drill the fire wall for brake booster?

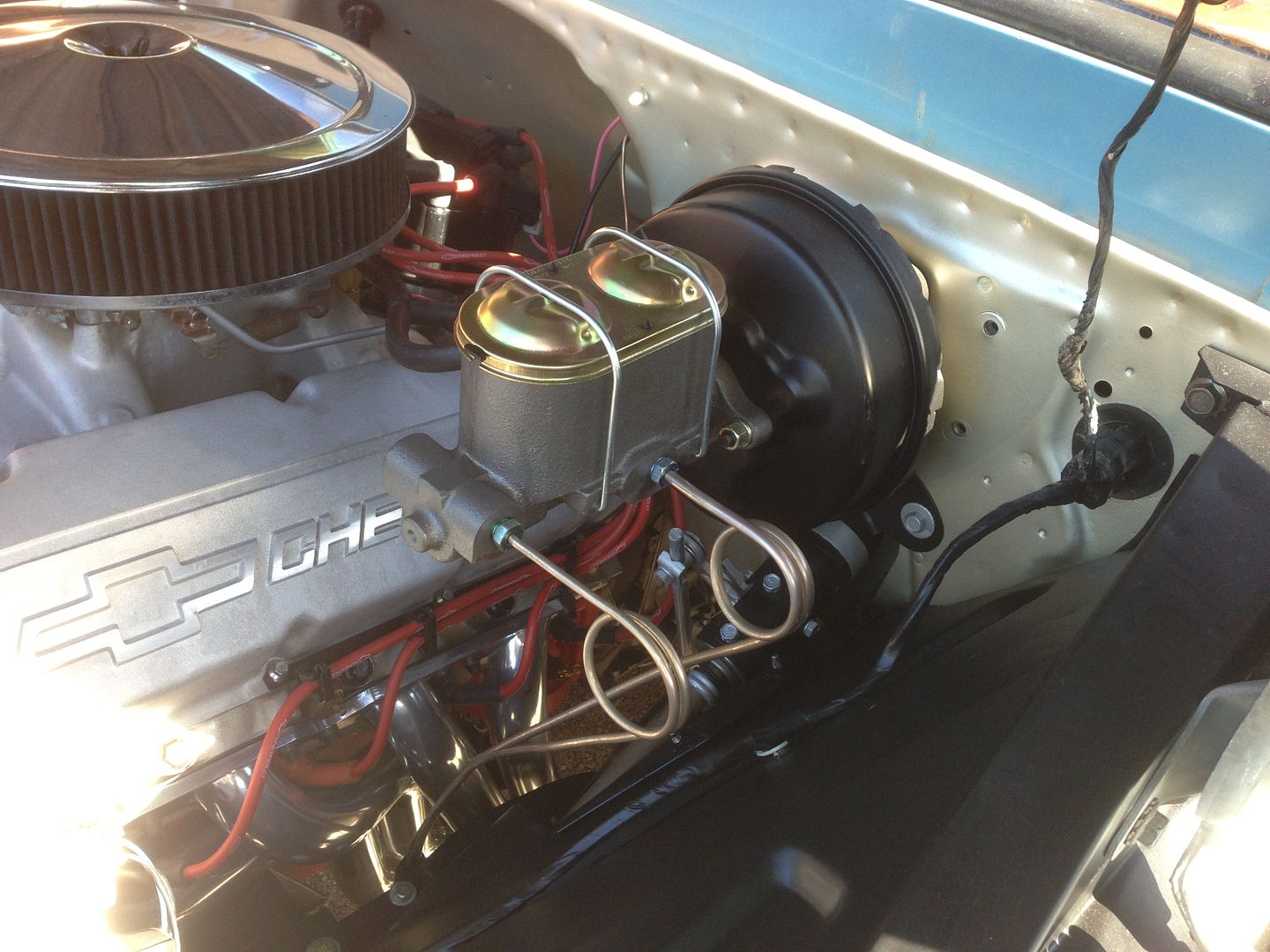

Here's what it looks like...

__________________

* My 63 C10 SWB Fleetside (converted to BBW): http://67-72chevytrucks.com/vboard/s...58#post6851558 @johnny_lamebridge on Instagram

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Feb 2009

Location: southeasternfoothillsofusa

Posts: 1,557

|

|

|

|

|

|

|

#13 | |

|

Registered User

Join Date: Mar 2014

Location: Cambridge, Ontario

Posts: 507

|

Re: Why not drill the fire wall for brake booster?

Quote:

Seriously though luvbowties... This was the booster supplied by CPP in their '63 C10 disc brake conversion kit. I just removed the supplied booster mounting bracket.

__________________

* My 63 C10 SWB Fleetside (converted to BBW): http://67-72chevytrucks.com/vboard/s...58#post6851558 @johnny_lamebridge on Instagram

|

|

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Feb 2009

Location: southeasternfoothillsofusa

Posts: 1,557

|

Quote:

.........NOT the prettiest and neatest installation, though(works great for rat rods!). The brackets seem to be both accurate and neat, and take out all the guesswork!!! Sam |

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jul 2015

Location: Seattle

Posts: 228

|

Re: Why not drill the fire wall for brake booster?

Here is my '76 booster and MC mocked up after cleaning, trimming the bracket and painting. Currently it's being held by one bolt in an original hole, so i'll have to drill a few more. The top hole on the bracket is one I drilled to get a high location on the bracket to secure it.

__________________

1961 Chevy Apache "BoomStick" -First build, lots of plans, little experience. What's the worst that could happen? http://67-72chevytrucks.com/vboard/s...d.php?t=694506 |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Nov 2013

Location: North Bend Wa

Posts: 355

|

Re: Why not drill the fire wall for brake booster?

I'll add my experience. I used the technique shown here to flush mount a power booster with a dual master cylinder on a 65 C20 with stock drum brakes. I drilled additional holes in the pedal at 1" and 1 1/2" below the stock hole. I started with 1" bore dual master cylinder that was for a manual disc brake square body C10 and mounted it on a 8" dual diaphragm booster. Thinking I didn't need a 1 1/8 master when I still had the stock front drums that had been run by a 1" single master cylinder stock. With the booster mounted flush to the firewall I didn't have the benefit of the booster being angled up for better push rod geometry and was limited to using the 1" lower hole as the 1 1/2" lower hole in the pedal arm would not work without binding. I adjusted the brakes but did not add a 10lb residual valve to start with and could not get the brakes to engage. I tried a 1 1/8" master cylinder for a power disc brake square body C10 and with this I got the brakes to engage with a lot of pedal travel and they were very grabby and hard to control. I was at the go big or go home point so I bought a 1 5/16" bore master cylinder for a 1980 C30. With this I had plenty of stopping power that was easy to control but still more pedal travel than I wanted. After adding a 10lb residual valve to the fronts I now have stopping power and pedal travel I am very happy with.

Side notes:I used master cylinders intended for front disc brakes hopping that I will change to front discs soon. I don't plane to add a residual valve to the rear as it may increase the tendency of the rears to lock up early. The 1" bore master cylinder was designed to have the front brakes plumbed to the rear master cylinder reservoir, the 1 1/8" master cylinder was designed to have the front brakes plumbed to the front reservoir, and the 1 5/16" bore master cylinder is designed to have the front brakes plumbed to the rear reservoir. Not saying anybody should do what I did, just sharing.

__________________

65 C20 292 4spd 4:56 Eaton HO52 |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Oct 2016

Location: san bernardino ca

Posts: 1,611

|

Re: Why not drill the fire wall for brake booster?

Just drill it.

|

|

|

|

|

|

#18 |

|

Moderator

Join Date: Aug 2011

Location: China Spring, TX

Posts: 7,280

|

Re: Why not drill the fire wall for brake booster?

Here are pics of the brake pedal assembly (off the truck) with the booster installed.

Capn Fabs bracket doesnt change the factory mounting holes and as you see the factory uses the bracket inside the truck for strength.

__________________

Master Chief, US Navy, Retired 1964 C10 Step-side Short Bed - In Progress 2009 2500HD Duramax LTZ 1948 GMC Panel 1956 Big Window Stepside 1953 5 Window Chevy Stepside 1932 Coupe New Seat Foam for Bench Seats? |

|

|

|

|

|

#19 | |

|

Registered User

Join Date: Dec 2014

Location: portland oregon

Posts: 292

|

Re: Why not drill the fire wall for brake booster?

Quote:

thanks for the visual, this make much more sense now

__________________

1961 c10 longbed - gone 1964 c10 swb |

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Nov 2013

Location: North Bend Wa

Posts: 355

|

Re: Why not drill the fire wall for brake booster?

Having the booster out a ways from the firewall a little like the CaptainFab bracket does would have decreased the angle of my push rod. With that I may have been able to use the hole I drilled 1 1/2" lower on the pedal arm and also a smaller bore master cylinder.

__________________

65 C20 292 4spd 4:56 Eaton HO52 |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Oct 2016

Location: san bernardino ca

Posts: 1,611

|

Re: Why not drill the fire wall for brake booster?

It looks cleaner with the booster next to the firewall.

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Nov 2013

Location: North Bend Wa

Posts: 355

|

Re: Why not drill the fire wall for brake booster?

I really like having it back out of the way as much as possible.

__________________

65 C20 292 4spd 4:56 Eaton HO52 |

|

|

|

|

|

#23 |

|

60-66 Nut

Join Date: Mar 2007

Location: Coeur d'Alene, Idaho

Posts: 23,246

|

Re: Why not drill the fire wall for brake booster?

Thank you Rocknrod. Most people just don't understand the importance of the booster/master assembly being bolted directly to the pedal bracket the way GM designed it to be.

__________________

Power Steering Box Adapter Plates For Sale HERE Power Brake Booster Adapter Brackets For Sale '63-'66 HERE and '67-'72 HERE and '60-'62 HERE and "60-'62 with clutch HERE Rear Disc Brake Brackets For Sale. Impala SS calipers HERE Camaro Calipers HERE D52 Calipers HERE 6 Lug HERE Hydroboost Mounting Plates HERE |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Oct 2016

Location: san bernardino ca

Posts: 1,611

|

Re: Why not drill the fire wall for brake booster?

If no one changed anything everything will still be stock nothing will be custom.

|

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Columbia, SC

Posts: 1,926

|

Re: Why not drill the fire wall for brake booster?

Here is my 2 cents. I have a 1963 inline 230 in my 1963 truck. I found a brake booster that would allow me to keep my 1963 factory air cleaner. The new brake booster with disc/drum MC was $99 delivered. You can see the complete installation process - LINK HERE TO MY BLOG POST.

I used the CaptainFab bracket because it still keeps the engine bay looking clean. I'm very pleased with how the brakes perform and how things look clean inside the engine bay.

__________________

My 65 C10 build: www.lugnutz65chevystepside.weebly.com Want to know more about T5 transmissions? My website has a T5 Info Page and a Step by Step T5 rebuild. |

|

|

|

|

| Bookmarks |

|

|